Low Pressure Die Casting (LPC) is an advanced casting technology mainly used to produce thin-walled and complex-shaped metal parts.

This technology avoids the common problems of pores and oil bubbles in high-pressure casting by injecting molten metal into the mold at a lower pressure, while improving material utilization and product quality.

Low pressure die casting is a process where molten metal is pushed into a mold from below using gentle air pressure. This article explains how this method works. We will list its main advantages and typical uses.

- Low Pressure Die Casting Process Principle

- Main features

- Process steps

- Application Areas

- Advantages and Disadvantages

Low Pressure Die Casting Process Principle

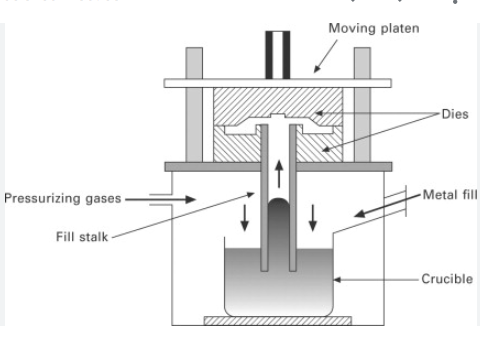

In the low-pressure die casting process, the mold is usually installed above a sealed crucible containing molten metal. The molten metal guides from the bottom to the mold cavity through a riser. Compressed air or inert gas injects below the liquid surface of the molten metal, pushing the molten metal upward and filling the mold cavity.

- 1.1. The Sealed Furnace and Fill Tube

- 1.2. Applying Controlled Air Pressure

- 1.3. Solidification and Cycle Completion

The Sealed Furnace and Fill Tube

A furnace holds the molten metal, like aluminum. A fill tube connects the furnace to the mold above it. The furnace is sealed so air pressure can build up inside.

Applying Controlled Air Pressure

Gentle air pressure pushes on the surface of the molten metal. This pressure forces the metal to rise slowly up the fill tube and into the mold cavity. The pressure stays on during filling.

Solidification and Cycle Completion

Once the mold is full, the metal cools and solidifies under pressure. After solidification, the air pressure is released. The leftover liquid metal in the tube flows back into the furnace. Then the mold opens to remove the part.

This method can effectively avoid oxidation and the formation of inclusions, thereby improving the purity and surface quality of the casting.

Main features

- Precise control

- Reduce defects

- Suitable for complex designs

- Production efficiency

Precise control

Low-pressure die casting can accurately control the filling of the mold cavity, ensuring the dimensional accuracy and surface finish of the casting.

Reduce defects

Due to the smooth flow of molten metal without turbulence, the casting has lower porosity and less oxide layer, which improves the overall quality of the casting.

Suitable for complex designs

Low-pressure die casting is particularly suitable for the production of parts with complex geometries and thin-walled structures, such as wheels, cylinders, etc. in automotive parts.

Production efficiency

Although low-pressure die casting is slower, its production cycle is short and suitable for mass production.

Process steps

- Mold preparation

- Molten metal processing

- Pressure filling

- Cooling and solidification

- Demolding and cleaning

Mold preparation

The mold usually made of high-temperature resistant materials. Coat with a ceramic coating to prevent molten metal from sticking.

Molten metal processing

After the molten metal heats to the appropriate temperature. It slowly injects into the mold cavity through a vertical pipe.

Pressure filling

Compressed air or inert gas injects below the liquid surface of the molten metal, pushing the metal upward and filling the mold cavity.

Cooling and solidification

The metal in the mold cavity cools and solidifies under pressure to form the final casting.

Demolding and cleaning

After the casting is cooled, the mold is opened, the casting is taken out and subsequently processed.

Application Areas

Low-pressure die casting widely uses in industries such as automobiles, aerospace, electronics and household appliances. For example, in the automotive industry, it uses to produce wheels, cylinder blocks and other high-performance light alloy parts.

Common Applications and Industry Use, this process is ideal for specific types of products.

- Automotive Wheels and Structural Parts

- High-Strength Aerospace Components

- Other Demanding Engineering Parts

Automotive Wheels and Structural Parts

Car wheels are a classic product for low pressure die casting. The process makes them strong, light, and good-looking. It is also used for chassis parts and suspension components.

High-Strength Aerospace Components

The aerospace industry needs very reliable parts. This process makes dense, high-integrity castings for aircraft fittings and engine parts.

Other Demanding Engineering Parts

Many industries use it for parts that must be strong and leak-tight. Examples include hydraulic blocks, pump housings, and high-quality valve bodies.

Advantages and Disadvantages

Advantages of the Low Pressure Die Casting Process

It offers several key benefits for part quality and production.

- Excellent Metallurgical Quality

- High Material Yield and Efficiency

- Good Surface Finish and Dimensional Accuracy

Excellent Metallurgical Quality

The metal fills the mold smoothly with little turbulence. This results in very few gas pores inside the part. Therefore, low pressure die casting produces strong, dense castings, which is good for safety parts.

High Material Yield and Efficiency

The process uses no risers and has a very small biscuit. Almost all the metal goes into the part itself. This means much less waste metal compared to other methods. It saves material cost.

Good Surface Finish and Dimensional Accuracy

The controlled fill produces parts with a smooth surface. Also, the mold cools evenly, which leads to stable dimensions. This often reduces the need for extra machining.

Disadvantages

- Slow production speed

- Not suitable for the production of thin-walled parts (thickness less than 3mm).

Low-pressure die casting is an efficient and reliable casting process, especially suitable for the production of high-quality, complex-shaped metal parts. Its wide application in multiple industrial fields proves its important position in modern manufacturing.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.