A380 aluminum alloy is widely recognized as the most versatile die-cast aluminum alloy.

In fact, it achieves the optimal balance among casting performance, mechanical strength, cost-effectiveness, and thermal stability.

Additionally, it exhibits excellent fluidity, making it suitable for complex shapes and thin-walled parts while maintaining high dimensional stability.

Moreover, it offers resistance to high temperatures and corrosion, furthermore, its electrical and thermal conductivity are outstanding.

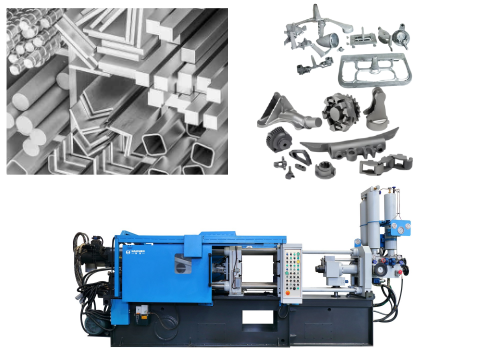

Aluminum for die casting,aluminum is one of the most commonly used materials in die casting, and its best choice depends on needs.

Characteristics and benefits of aluminum

- Lightweight and high strength

- Corrosion resistance

- High thermal conductivity

- Recyclability

- Good processability

Lightweight and high strength

Aluminum has a lower density but higher strength and hardness, making it suitable for manufacturing lightweight parts.

Corrosion resistance

In addition, aluminum has excellent corrosion resistance, especially when exposed to moisture or chemical environments.

High thermal conductivity

At the same time, aluminum has a higher thermal conductivity than many other metals, making it very useful in applications where heat dissipation is required.

Recyclability

Secondly, aluminum is a fully recyclable material with environmental advantages.

Good processability

Aluminum has better processing properties than iron, steel and titanium, and is easy to form and polish.

Aluminum die casting alloys

- ADC12 (Al-Si8Mg)

- A380 (Al-Si11Cu3)

- A360 (Al-Si12Mg)

- A383(ADC12)

- A390 (Al-Si12Mg4Cu)

ADC12 (Al-Si8Mg)

This is one of the most commonly used aluminum die casting alloys with good mechanical properties, flowability, and surface finish.

A380 (Al-Si11Cu3)

This alloy offers a balance of mechanical and casting properties and is preferred for many applications.

A360 (Al-Si12Mg)

It has higher strength and corrosion resistance, and is suitable for parts that require higher mechanical properties.

A383(ADC12)

Similar to ADC12, but with slightly lower mechanical properties.

A390 (Al-Si12Mg4Cu)

It has higher corrosion resistance and strength, and is suitable for high temperature environments.

Selection of the best aluminum die casting alloy

- Application requirements

- Cost and performance balance

- Specific applications

Application requirements

If high strength and high temperature resistance are required, A360 or A390 can be selected; If good flow and surface finish are required, ADC12 or A380 can be chosen.

Cost and performance balance

The ADC12 and A380 are widely recommended for their excellent overall performance and low cost.

Specific applications

For example, A390 is suitable for components that require high strength and corrosion resistance, such as automotive engine blocks.

Emerging aluminum die-casting alloys

- Al-Si alloy properties

- Al-Si-Mg alloys Properties

- Al-Mg alloy Properties

- Al-Mg alloy Properties

- Al-Cu alloy properties

- Al-Mg-Cu alloy performance

- Ultra-high strength aluminum alloy Performance

- New high-strength and toughness aluminum alloy Performance

- Other new alloys Properties

Al-Si alloy properties

Al-Si alloy is the most widely used series of die-cast aluminum alloys, with good thermoplastic rheological properties, small linear shrinkage and high temperature strength.

By adding rare earth elements (such as Fe, Zn, Ni, etc.), the microstructure and mechanical properties of the alloy can be optimized.

Mainly used in the power system, transmission system, steering system, chassis assembly, body and other components of the automobile.

Al-Si-Mg alloys Properties

Al-Si-Mg alloys form Mg2Si solid solutions by adding Mg and Cu elements.

Which significantly improves the comprehensive properties of the alloys.

This alloy has high elongation and good corrosion resistance.

Suitable for automotive body structural parts, such as body shells, brackets and bases

Al-Mg alloy Properties

Al-Mg alloy has high strength and good corrosion resistance, but its elongation is low.

Use in automobiles, communications, construction machinery and other fields.

Al-Cu alloy properties

Al-Cu alloy has high strength and good plasticity, but its elongation varies greatly.

Mainly used in the manufacture of auto parts.

Al-Mg-Cu alloy performance

Al-Mg-Cu alloy combines the advantages of Al-Mg and Al-Cu alloys, has high strength and good corrosion resistance, and is suitable for the manufacture of auto parts.

Ultra-high strength aluminum alloy Performance

Ultra-high strength aluminum alloy significantly improves the strength, plasticity and wear resistance of the material by adding trace elements, surface composite treatment and metal matrix composite materials.

It is suitable for aerospace, automobile manufacturing, electronic communication and other fields.

New high-strength and toughness aluminum alloy Performance

The new high-strength and toughness aluminum alloy forms a solid solution of Mg2Si by adding Mg and Cu elements, which has high elongation and good corrosion resistance.

For example, Auralic-2 and Auralic-3 alloys have a yield strength of up to 169 MPa, an elongation of 10%, and a tensile strength of up to 190 MPa at a high temperature of 200°C.

It is suitable for automobile body structural parts.

Other new alloys Properties

including Silafont-300, Msimal-59, Castasil-37 and other alloys, these alloys significantly improve the strength and corrosion resistance of materials by adding rare earth elements or fiber reinforced materials.

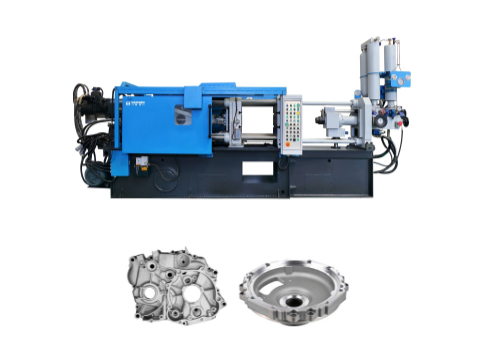

Which alloy should we choose for your project?

No one alloy is suitable for all applications.

Therefore, Haichen suggests that you should carefully consider which aspects are most important to your production.

For example, A380 alloy is the most widely used casting alloy on the market and is suitable for a variety of applications, such as the casting of aluminum road studs.

However, depending on the specific application of the final product, the A380 may not be the best choice.

Therefore, Haichen also offers many customers an alternative material, A360, which has better corrosion resistance.

While casting is more difficult, in many cases this challenge can be overcome. In general, by identifying which properties are more important to your specific situation, you can more easily determine which alloy is best for your application.

You can visit our die casting services page to learn more about the die casting solutions offered by Haichen.