Cold chamber die casting method is a process used to produce metal parts with high precision and good surface finish.

It is particularly suitable for metals with high melting points, such as aluminum, magnesium, and copper alloys, which would otherwise damage the plunger and other components if cast using the hot chamber method.

Cold chamber die casting method manufacturing process

Cold chamber die casting is an efficient and reliable metal die casting process, especially suitable for the production of precision parts with high melting point metals.

Melting the Metal

- Melt the metal in a separate furnace, typically outside the die casting machine.

- This allows for better control over the temperature and composition of the molten metal.

Transferring the Metal

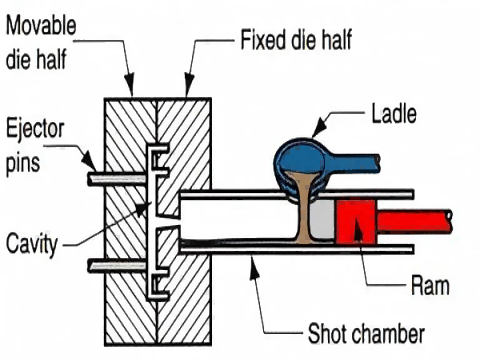

- Once the metal reaches the desired temperature, use a ladle to transfer the molten metal from the furnace to the cold chamber.

- The cold chamber is a cylindrical sleeve attached to the die casting machine.

Injection

- A hydraulically operated plunger then forces the molten metal from the cold chamber into the die cavity.

- The die is a metal mold that has been precision-machined to the shape of the desired part.

Cooling and Solidification

- The molten metal cools and solidifies within the die cavity, taking the shape of the die.

- Cooling channels within the die help to speed up this process.

Ejection

- Once the metal has solidified, the die opens, and ejector pins push the casting out of the die cavity.

Trimming and Finishing

- Remove the casting from the machine, and any excess material (such as flash or sprues) is trimmed off. Additional finishing processes, such as machining or surface treatment, may be performed as needed.

Advantages of cold chamber die casting method

High Precision: The cold chamber method allows for the production of parts with tight tolerances and complex geometries.

Good Surface Finish: The process produces parts with smooth surfaces, often reducing the need for additional finishing.

Suitable for High Melting Point Metals: It is ideal for metals that would damage the equipment in a hot chamber process.

Haichen cold chamber die casting machine supplier

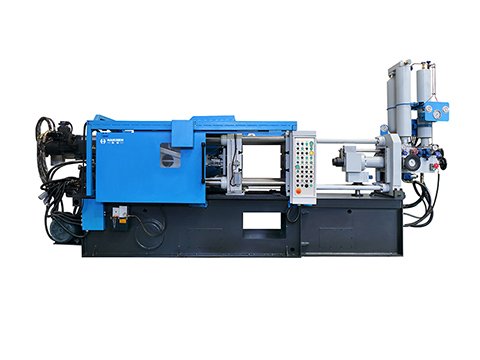

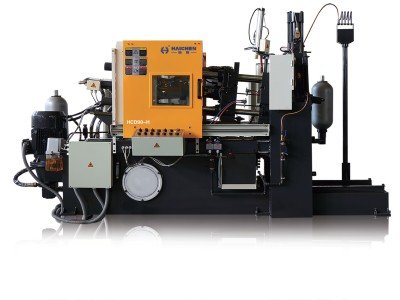

Haichen is a well-known manufacturer and supplier of die casting machines, including cold chamber die casting machines and hot chamber die casting machines. We produce high-quality, reliable, and efficient die casting equipment that caters to various industries.

And Haichen’s cold chamber die casting machines can handle metals with high melting points, such as aluminum, magnesium, and copper alloys, making them suitable for a wide range of applications.

If there is any demand for cold chamber die casting machines, welcome to consult us.