Die casting plunger rod is a core component that is responsible for transmitting the force generated by the hydraulic system to the shot sleeve, thereby propelling the molten metal into the mold cavity at high speed.

The performance of the injection rod depends on the design accuracy such as straightness and diameter, the thermal stability of the material, and the maintenance conditions such as alignment and lubrication.

Based on the above, the core function of the injection rod is to act as a force transfer medium, ensuring that molten metal is accurately and quickly injected into the mold cavity under high pressure while withstanding the harsh working environment.

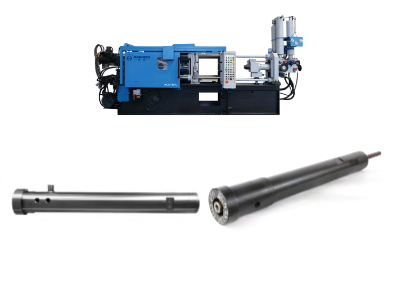

Die casting plunger rod

To begin with, the plunger rod is a crucial component of the injection system in a die casting machine, acting as a power transmission element.

It connects the hydraulic cylinder to the plunger tip, and during the die casting cycle, its axial movement pushes the plunger tip inside the shot sleeve, thereby forcing molten metal into the die cavity.

This process operates under high pressure and high temperature conditions; therefore, the plunger rod must exhibit high strength and durability.

Specifically, in cold-chamber die casting, operators first pour molten metal into the shot sleeve, and then the plunger rod rapidly advances to complete the injection.

Injection Rod-Related Components

Injection Head: Connected to the front end of the plunger rod, it provides a sliding seal on the cartridge holster.

It is made of special steel or beryllium copper and often includes wear rings for enhanced sealing and wear resistance.

The tip is cooled directly through the coolant system of the plunger rod.

Injection Barrel: Acts as a guide and container for molten metal.

The plunger rod moves within it, and the durability of the sleeve is crucial to prevent wear and tear.

The function of die casting plunger rod

In the die casting process, the function of the plunger rod is to push out the molten metal from the injection nozzle or barrel and inject it into the cavity of the mold.

So as to complete the filling and molding of the metal.

- Transfer of Molten Metal of die casting plunger rod

- High-Pressure Injection

- Improving casting accuracy and quality

- Reducing porosity and condensation defects

- Speed & Pressure Control

- Durability & Wear Resistance

- Extend Equipment Life and Increase Productivity

Transfer of Molten Metal of die casting plunger rod

The plunger rod connects to the plunger (piston) inside the shot sleeve.

When the machine cycles, the plunger rod moves forward, forcing the molten metal from the shot sleeve into the die cavity.

High-Pressure Injection

The plunger rod applies significant pressure (typically 1,000 to 20,000 psi) to ensure the molten metal fills the die completely before solidifying.

Improving casting accuracy and quality

The precise design and material selection of the plunger rod is critical to ensuring the accuracy and quality of the casting.

For example, plunger rods are often made of high-strength steel and heat-treated to improve their wear and heat resistance.

In addition, the sealing performance between the plunger rod and plunger head affects the surface quality of the casting and the occurrence of internal defects..

Reducing porosity and condensation defects

During the die casting process, if the molten metal flows into the mold too quickly or at too low a temperature, it can lead to porosity or condensation defects.

Therefore, we need to strictly control the movement speed and pressure of the plunger rod to ensure that the metal flows smoothly into the mold and cools and solidifies properly.

Speed & Pressure Control

The plunger rod moves in a precisely controlled manner, often in two stages—slow for air evacuation and then fast for filling—to optimize casting quality.

Durability & Wear Resistance

Since it operates under high pressure and temperature, the plunger rod is usually made from hardened steel or other durable alloys to resist wear and deformation.

Extend Equipment Life and Increase Productivity

To extend the life of the plunger rod and increase productivity, a plunger sleeve is often installed between the plunger rod and the injection nozzle.

The sleeve not only protects the plunger rod from wear and tear, but also reduces friction, which reduces maintenance costs and extends equipment uptime.

Die casting plunger rod supplier: Haichen Machinery

Haichen Machinery is a well-known supplier of die casting machine plunger rods and other related components for the die casting industry.

We specialize in providing high-quality, durable, and precision-engineered plunger rods that are essential for the efficient operation of cold chamber die casting machines.

Key Features of Haichen Machinery Plunger Rods

Material: High-quality alloy steel (e.g., H13) with heat treatment for wear resistance.

Precision Machining: Ensures smooth operation and longevity.

Surface Treatment: Often includes nitriding or chrome plating for enhanced durability.

Compatibility: Designed to fit various die casting machine brands (e.g., LK, Buhler, Frech, UBE, Toshiba, etc.).

Customization: Available in different sizes and specifications to match machine requirements.

If you need plunger rods, plunger tips, sleeves, or other die casting spare parts, we can provide it.