The function of jet cooling in die casting is to rapidly cool molten metal using high-velocity jets, ensuring uniform solidification.

Jet cooling is a key step in die casting production, which can significantly improve the efficiency and quality of finished products. This technology uses high-pressure water (or gas) to spray into the mold to quickly cool down and solidify the molten metal.

Especially when manufacturing thin-walled complex parts, uniform cooling must be maintaine – this is directly related to product dimensional accuracy and defect control.

Next, we will explain the specific role of jet cooling in die casting and analyze its actual value to product quality.

Core functions and working principles of jet cooling

Jet cooling actively manages heat during die-casting. This technology directs high-pressure water flow to precisely control mold temperature. Its main goal is to maintain consistent temperature distribution across the mold surface.

- Workflow

- Thermodynamic principle

Workflow

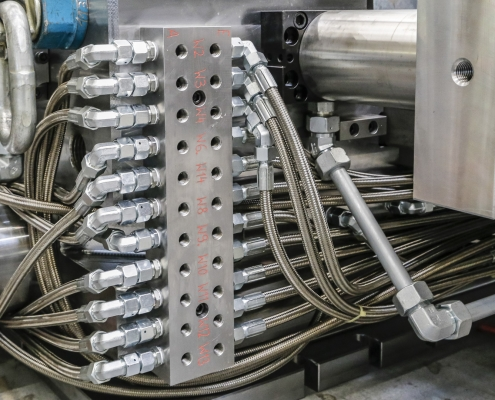

- Intensive cooling phase: A high-pressure pump (up to 20 bar) injects cooling water into the mold. This water is delivered through a small pipe with a diameter between 1.2 and 2.8 mm, directly acting on the core pin of the mold or the area with particularly high temperature for rapid cooling.

- Removal of residual water: After the cooling step, the system will immediately blow the inside of the pipe with compressed air. This operation is to ensure that there is no residual water in the pipe, so as to avoid the risk of water turning into steam and causing explosion in a high temperature environment.

- Check the tightness: Before starting the next working cycle, the system automatically pressurizes the pipe. This pressurization process is to check whether the sealing performance of the entire system is good and confirm that there are no water leaks, so as to ensure that the operation of the next cycle is safe.

Thermodynamic principle

The core function of jet cooling is to achieve rapid cooling of the mold by precisely controlling the high-pressure water flow. When the high-pressure water flow directly impacts the high-temperature mold surface, it will cause nucleate boiling. This process includes two key heat dissipation mechanisms:

- Phase change heat absorption: water vaporizes instantly when it contacts the high-temperature surface, absorbing a large amount of heat (the latent heat of vaporization is much higher than the specific heat capacity of water);

- Forced convection: The strong impact force generated by the high-pressure water flow continuously removes the heated liquid and replenishes the low-temperature cooling water, significantly enhancing the heat exchange.

Compared with traditional cooling methods (such as natural convection or low-pressure water flow), this combined heat dissipation mechanism increases the heat exchange efficiency per unit time by 30-50%. In actual industrial applications, this technology also includes subsequent operations: compressed air is introduced to remove residual water at the moment of cooling, and the system sealing is ensured by pressure detection to ensure the safety of the cycle.

Five core values of jet cooling for die casting quality

- Eliminate defects and improve product yield

- Shorten cycle time and increase production capacity

- Extend mold life and reduce maintenance costs

- Efficient use of energy and resources

- Breaking through the bottleneck of complex structure manufacturing

Eliminate defects and improve product yield

Rapid cooling reduces metal shrinkage around the core pin, significantly reduces shrinkage rate (up to 30%+) and welding cold shut defects.

Avoid aluminum adhesion and surface cracks caused by local overheating, and improve the surface finish of castings.

Shorten cycle time and increase production capacity

Casting solidification speed is increased by 40%+, mold opening time is shortened. And single machine daily production capacity is increased by 15-20%.

Extend mold life and reduce maintenance costs

Core pin thermal stress is reduced by 50%+, fracture and plastic deformation are prevented. And mold life is extended by 30-60%.

Reduce the use of release agent (reduced by about 25%), and indirectly reduce mold corrosion.

Efficient use of energy and resources

Closed-loop systems (such as Ahresty JECSS-M) save 90%+ water and consume only 1/3 of traditional water cooling.

Atomized spray reduces the amount of coolant by 60% compared to immersion cooling.

Breaking through the bottleneck of complex structure manufacturing

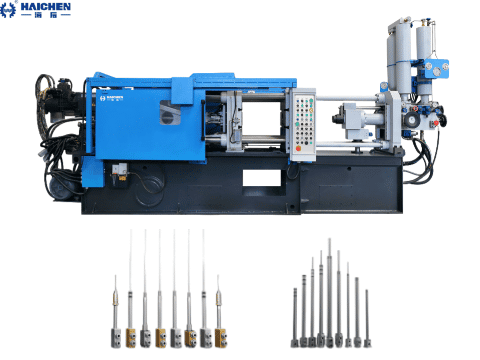

It can cool ultra-fine core pins of φ4-10mm, solving the problem that traditional cooling cannot cover deep cavity and thin wall areas.

Technical Implementation and System Composition of Jet Cooling

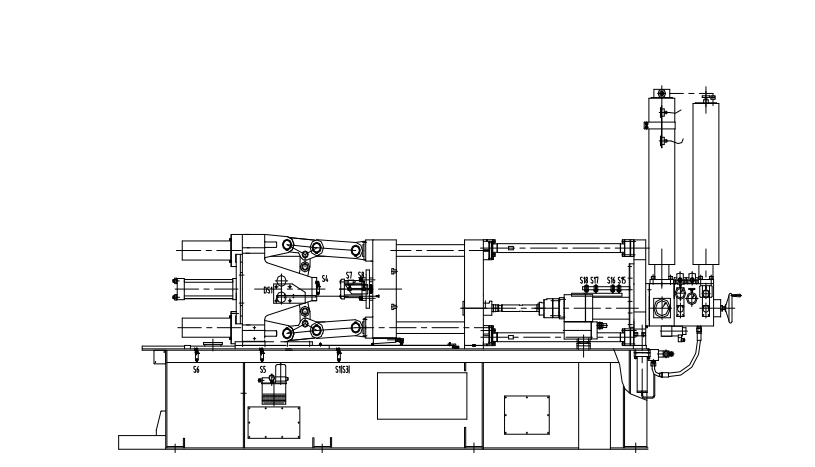

The jet cooling system achieves precise temperature reduction for mold hot spots by integrating high-pressure water lines, precision control valves, and sensors. Core components include a high-pressure pump station, solenoid jet valves, dedicated cooling pipes, and an air-blow clearing unit.

The workflow starts at a specific phase of the die casting cycle. The controller signals specific jet valves to open, directing high-pressure coolant through small-diameter pipes to strike high-temperature mold areas (e.g., cores).

Upon contact, heat is rapidly removed via phase-change absorption and forced convection. After injection, compressed air immediately purges the pipes to remove residual liquid. Followed by a seal integrity check before the next cycle.

HAICHEN’s Integrated Intelligent Jet Cooling Solution

HAICHEN integrates jet cooling as part of its intelligent temperature control system, not as a standalone function. We plan jet point layouts and cooling strategies based on thermal analysis of the customer’s part and mold, with deep linkage to the main machine control.

- System Integration and Process Coordination

- Case Study: Solving Warpage in Large Thin-Wall Parts

System Integration and Process Coordination

The HAICHEN machine control system allows programmable control of each jet valve’s timing, duration, and pressure. These parameters are set in coordination with the injection profile. And conventional cooling in other mold areas to achieve dynamic thermal balance management. For instance, jet cooling can be triggered immediately after filling for local thick sections to balance the overall solidification rate.

Case Study: Solving Warpage in Large Thin-Wall Parts

A customer producing large thin-wall aluminum battery trays for new energy vehicles faced issues. The part had numerous reinforcing ribs (5mm thick) inside. Which created severe hot spots under traditional cooling, leading to poor flatness and internal shrinkage.

- Challenge: The slender cores forming the ribs were difficult to cool, as conventional water channels couldn’t be installed. Causing significant thermal stress from temperature differences.

- HAICHEN Solution: On an HAICHEN 8800T machine, we integrated a targeted jet cooling system for 12 key rib cores in the mold. The system initiated a 3-second high-pressure water mist spray to the specified cores within 0.5 seconds after metal filling.

- Result: Cooling efficiency for the critical hot spots improved by over 60%, reducing the overall temperature gradient. The part’s flatness was controlled within 0.3mm, and the pass rate from internal X-ray inspection increased from 88% to 99.5%. The production cycle time was also shortened by approximately 7%.

In the die casting process, jet cooling plays a key role. It directly improves the quality of the finished casting, production efficiency and dimensional accuracy by rapidly cooling the core components of the mold. Whether it is automotive parts, electronic product housings or industrial equipment components. This technology is an indispensable core link in the modern die casting process.

Leading manufacturers such as HAICHEN can provide customers with full-link solutions from equipment to processes by integrating intelligent injection systems. And establish technological barriers in high-end markets such as new energy vehicles and 3C precision parts.