In die casting, a thermocouple is a temperature – sensing device that provides real – time temperature measurements, ensuring precise control and monitoring of the molten metal and mold temperatures to maintain production quality and efficiency.

In the die – casting industry, precision and control are paramount for producing high – quality parts. One of the key components that facilitate this precision is the thermocouple.

These temperature – sensing devices provide real – time feedback, which is crucial for maintaining optimal conditions and enhancing process reliability.

This article will delve into the function of thermocouples in die – casting and how they contribute to the overall process.

By understanding the role of thermocouples, manufacturers can gain deeper insights into optimizing their operations and improving part quality.

Understanding Thermocouples

- Definition

- Types

Definition

A thermocouple is a temperature – sensing device that consists of two dissimilar metals joined together at one end. Heating the junction produces a measurable small voltage that converts to a temperature reading.

Types

There are several types of thermocouples, each with its own temperature range and sensitivity. Common types used in die casting include:

- Type K: Made of chromel and alumel, it is one of the most widely used thermocouples due to its wide temperature range and reliability.

- Type J: Made of iron and constantan, it is known for its high sensitivity and is often used for lower temperature applications.

The function of the thermocouple in Die Casting

- Temperature Monitoring

- Process Control

- Safety

Temperature Monitoring

Operators use thermocouples to monitor molten metal temperature, mold conditions and other critical die casting machine components. This real – time data is essential for maintaining the optimal temperature conditions for the casting process.

Process Control

By providing accurate temperature readings, thermocouples allow operators to make adjustments to the casting process as needed. This can include adjusting the injection speed, pressure, or cooling time to ensure consistent part quality.

Safety

Thermocouples also play a crucial role in ensuring the safety of the die casting operation. By monitoring the temperature of the molten metal and the mold, they can help prevent overheating, which can lead to defects or machine damage

Choosing the Right Thermocouple

- Application Needs

- Machine Compatibility

Application Needs

The choice of thermocouple depends on the specific requirements of the die casting application. Consider factors such as temperature range, sensitivity, and durability.

Machine Compatibility

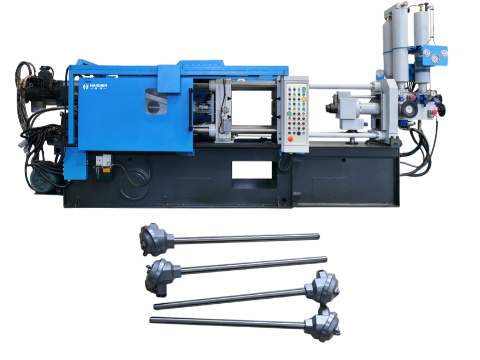

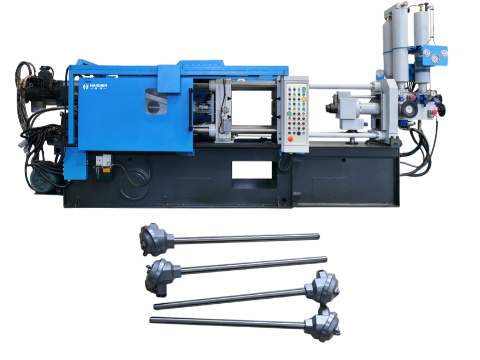

Ensure that the thermocouple is compatible with the die casting machine and its control system. HAICHEN‘s machines are designed to work with a variety of thermocouples, providing flexibility and reliability.

HAICHEN: Your Partner in Die Casting Excellence

At HAICHEN, we specialize in manufacturing high – quality die casting machines equipped with advanced features, including thermocouples, to ensure precise temperature control. Our machines feature precision, efficiency, and safety, ensuring every part produced meets the highest standards. Whether you are starting a new project or upgrading your existing equipment, HAICHEN has the solutions to meet your needs.

Understanding the function of the thermocouple in die casting is essential for achieving high – quality and consistent castings. By monitoring and controlling temperature, thermocouples play a crucial role in the die casting process.