The gooseneck in die casting is a crucial component that transfers molten metal from the injection system to the mold cavity, ensuring smooth and efficient metal flow during the casting process.

The gooseneck is a vessel that houses the casting chamber and immerses itself in the furnace melt. It transports molten metal from the furnace to the die.

Manufacturers typically make this component from forged or cast hot-forming steel.

Forged goosenecks have higher material homogeneity, while cast goosenecks are less prone to stress cracks due to their even wall thickness transitions.

This article will provide a detailed explanation of what the gooseneck is and its importance in die – casting operations.

Key Features of the Gooseneck

Shape: The gooseneck is typically curved or bent, resembling the neck of a goose, which gives it its name.

Material: Made from heat-resistant materials to withstand high temperatures and corrosive molten metals.

Function: Acts as a conduit for transferring molten metal from the furnace to the injection system.

Integration: In hot-chamber machines, the gooseneck submerges itself in the molten metal, enabling quick and efficient metal delivery.

How the gooseneck works:

- The gooseneck immerses itself in the molten metal in the furnace.

- When the plunger (or piston) retracts, molten metal fills the gooseneck.

- The plunger then pushes the metal through the gooseneck and into the die cavity under high pressure.

- After the metal solidifies in the die, the plunger retracts, and the process repeats.

Applications of the gooseneck:

- The gooseneck is primarily used in hot-chamber die casting, which is ideal for casting low-melting-point metals like zinc, magnesium, and lead alloys.

Advantages of the gooseneck:

- Faster cycle times compared to cold-chamber die casting.

- Efficient metal transfer due to the gooseneck’s direct contact with the molten metal.

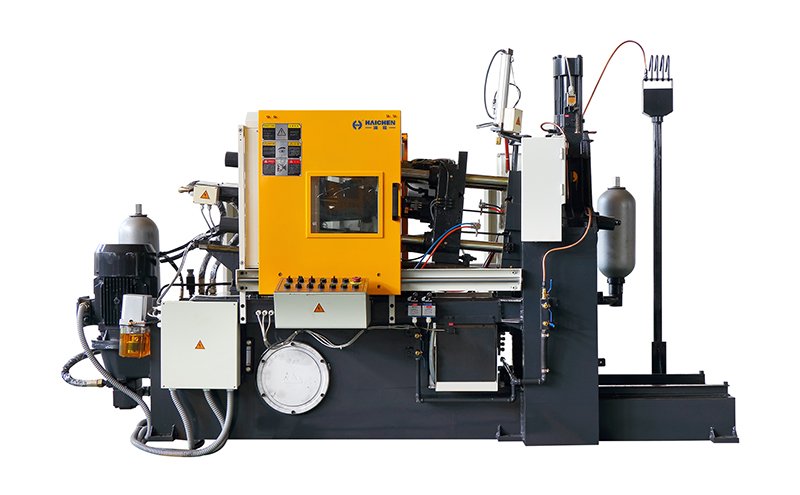

Haichen hot chamber die casting machine gooseneck

Haichen is a company known for producing high-quality die casting machines. In a Haichen hot-chamber die casting machine, the gooseneck is a critical part, as it is in all hot-chamber machines.

Key Features of Haichen Gooseneck

Precision Engineering: Haichen goosenecks are precision-engineered to ensure smooth and efficient metal flow, minimizing turbulence and defects in the cast parts.

Heat Resistance: Made from materials that can withstand the high temperatures of molten metals without degrading.

Corrosion Resistance: Designed to resist corrosion from molten metals, ensuring a longer lifespan.

Ease of Maintenance: Haichen machines feature a design that ensures easy maintenance, including the gooseneck, to reduce downtime.

Applications

Haichen hot-chamber die casting machines, including their goosenecks, are commonly used for casting:

Zinc alloys: Widely used in automotive, electronics, and consumer goods.

Magnesium alloys: Used in lightweight components for aerospace and automotive industries.

Lead alloys: Used in batteries and radiation shielding.

In summary, the gooseneck is a critical component in hot-chamber die casting machines, enabling efficient and rapid delivery of molten metal into the die cavity.