Heat treatment for die casting usually includes these:

- Annealing

- Normalizing

- Quenching

- Tempering

- Solution Treatment

These steps improve the mechanical properties of die castings, such as mechanical strength, fatigue strength, ductility and impact strength, as well as dimensional stability.

Common methods include solution heat treatment and aging, which together create the highest strength properties.

Other treatments like annealing reduce hardness and stress, while stress relieving at lower temperatures reduces residual stress.

The specific process, like T5, T6, or T7 for aluminum, depends on the alloy and the desired properties, such as increased hardness, ductility, or thermal stability.

Annealing

The purpose of annealing is to reduce the hardness of the material and improve the plasticity and toughness.

Soft annealing is usually employed, heated to 850°C, then cooled to 650°C at a rate of 10°C per hour, and finally air-cooled.

For zinc die castings, one of the heat treatment methods recommended by Haichen is annealing, which can reduce deformation, improve plasticity, and extend life.

Normalizing

Normalizing is to heat the steel to 30~50 °C above AC3, keep it warm and cool it in the air to obtain a finer pearlite structure.

The cooling rate after normalizing affects the amount of ferrite precipitated and thus the hardness.

Quenching

Quenching is to heat the steel above the phase change temperature (AC1 or ACm).

And after heat preservation, at a fast cooling rate (such as water cooling)

That is greater than the critical cooling rate of the steel to obtain a martensitic structure with high hardness.

600-900°C, usually preheated in two stages, the first stage is at 600-650°C, and the second stage is at 820-850°C.

Austenitization temperature: 1000-1030°C.

Quenching medium: high-speed gas/circulating atmosphere, vacuum quenching, salt bath furnace or flow pellet furnace, etc.

Tempering

Tempering is a heat treatment process that reheats quenched parts to a temperature below the AC1 line, with enough time to stay warm, and then cools down to room temperature.

Temperature:Die-casting die tempered three times, hot forging die and extrusion die tempered twice to achieve the required hardness

Holding time:Lasts for two hours and guarantees the tempering temperature to avoid tempering brittleness.

Solution Treatment

Involves heating the casting to a specific temperature, dissolving alloying elements into a single phase, and then quenching to retain that phase at room temperature.

Haichen recommends this heat treatment for aluminum die castings because it significantly improves mechanical properties (strength, hardness, corrosion resistance) and dimensional stability.

And reduce the impact of casting defects such as porosity and grain roughness.

Why use heat treatment?

Haichen recommends that every customer heat treat die castings, because heat treatment is widely used in the manufacturing process of metal materials and castings to improve the product performance of die castings by changing the internal structure and properties of the materials.

- Improved Mechanical Properties

- Mitigating Residual Stress

- Improved processing performance

- Extended Life and Reliability

- Control Microstructure

Improved Mechanical Properties

Heat treatment can significantly improve the strength, hardness, toughness, wear resistance, and ductility of materials.

For example, the strength of the alloy can be increased several times by several times through solution treatment and aging treatment such as the hardness of LM25 alloy changes over time.

Heat treatment also improves the processability of materials (e.g., increased machinability) and corrosion resistance (e.g., corrosion resistance of aluminum-silicon alloys).

Mitigating Residual Stress

Rapid cooling during casting can lead to internal residual stresses, potentially triggering deformation, cracking, or premature failure.

Heat treatment eliminates or relieves these stresses through heating and cooling processes, improving dimensional stability and longevity.

Improved processing performance

Heat treatment can soften the material such as annealing treatment, facilitate subsequent processing such as cutting, forming, and reduce work hardening.

Extended Life and Reliability

By optimizing material properties (e.g., improving wear resistance and fatigue resistance), heat treatment can extend the service life of parts and reduce maintenance costs.

Control Microstructure

Heat treatment achieves precise control of properties by changing the grain structure, phase composition, and microstructure distribution of materials.

Heat Treatment Process

The thermal treatment process for die casting is structured around four sequential steps.

Each step plays an important part in stabilizing the size & crystalline structure of the parts.

Enhancing their mechanical properties, improving their machining performance, and removing any internal stress.

- Casting Solidification

- Solution Annealing

- Quenching

- Artificial Aging

Casting Solidification

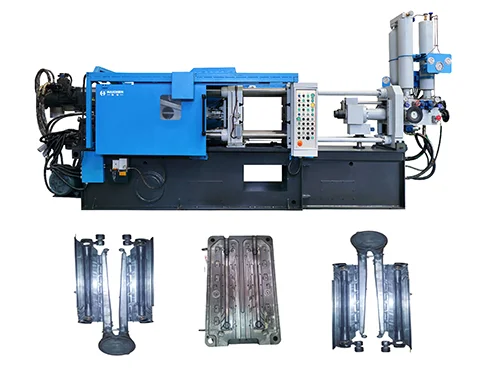

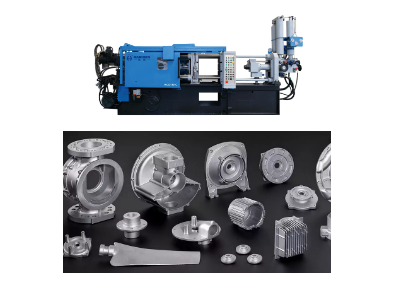

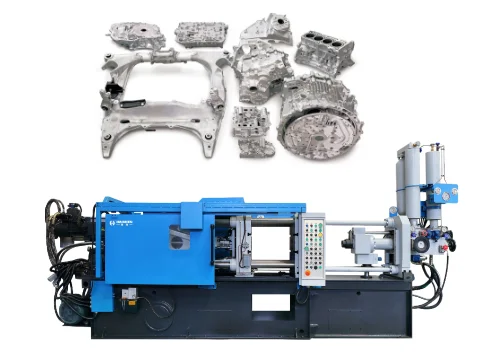

Injecting molten metal into the mold cavity at high speed and rapidly cooling the metal down is the initial step of die casting.

This complete process is done with die casting machines.

Fast cavity filling and fast cooling removes any chance of filling gaps in the mold or disturbed structural stability of the parts.

Solution Annealing

Annealing helps with stabilizing the shape and size of die casting parts.

It’s an important step which also removes the casting stress of the parts caused by machining.

Annealing of die casting parts is done at 450-490 ℃ temperature for a brief time.

Quenching

Die casting parts undergo solution treatment, also known as cold treatment, to maximize the dissolution of reinforcing elements.

This process involves annealing or heating the parts to around 500°C for several hours, followed by rapid quenching in water at 60-100°C.

Artificial Aging

Aging encompasses a low-temperature tempering technique that includes both natural and artificial aging.

Natural aging refers to the aging of parts at ambient room temperature.

While artificial aging involves subjecting them to temperatures ranging from 120 to 280℃ for extended durations.

Incomplete artificial aging

It is performed at ~120℃ temperature for 3-4 hours.

Incomplete artificial aging of die casting parts increases their tensile strength, toughness, and plasticity at the cost of lower corrosion resistance.

Complete artificial aging

It is performed at ~150-180℃ temperature for >5 hours.

It sufficiently increases the tensile strength of parts at the cost of lower elongation.

Over-aging

It is performed at ~280℃ temperature for >3 hours.

It strengthens the parts by increasing their stress resistance and corrosion resistance.

Haichen‘s Heat Treatment Specifications

- Equipment requirements

- Operation specification

Equipment requirements

The annealing furnace should be closed, insulated, and equipped with an exhaust device; Local air supply and cooling devices should be installed at the job post.

During heat treatment, especially when heated to high temperatures without protection, this can easily lead to scrapping of the mold or burning the surface layer.

For this reason, Haichen usually uses equipment such as vacuum furnaces, salt bath furnaces or inert gas furnaces for heat treatment.

Operation specification

Haichen requires the operator to handle the material as gently as possible when loading and unloading to reduce the noise caused by the collision of the casting.