Aluminum pressure die casting is a highly efficient and precise manufacturing process used to produce complex metal parts with tight tolerances.

Aluminum pressure die casting is a highly efficient manufacturing process used to produce complex and high – quality metal parts. This process involves injecting molten aluminum into a mold cavity under high pressure, ensuring precise and consistent part production.

Understanding the detailed steps and significance of each stage in the aluminum pressure die – casting process is crucial for manufacturers aiming to achieve high – quality results and maintain production efficiency.

This article will provide a comprehensive overview of the aluminum pressure die – casting process, explaining each step and its importance in delivering high – quality parts.

By mastering these steps, manufacturers can optimize their production processes, reduce defects, and enhance overall part quality.

Design and Tooling

- Design Phase: Engineers design the part using computer-aided design (CAD) software. The design must consider factors such as part geometry, wall thickness, draft angles, and the need for any internal features.

- Tooling: A two-part mold, typically made from high-grade steel. The mold consists of a stationary half (cover die) and a moving half (ejector die). The mold cavity can match the desired shape of the part. The tooling can ensure accurate replication of the part.

Preparation of the Die

- Cleaning: The die can remove any residual metal, lubricants, or debris from previous castings. This is crucial to ensure a smooth surface finish and prevent defects.

- Lubrication: A release agent is applied to the die surface. This helps in easy ejection of the part after solidification and also protects the die from excessive heat and wear.

Metal Preparation

- Material Selection: Aluminum alloys have excellent strength-to-weight ratio, corrosion resistance, and good mechanical properties. The most common alloys include A380, A360, and A356.

- Melting: Melting the aluminum alloy in a holding furnace. The temperature can ensure the metal is at the optimal casting temperature, typically around 650-700°C (1200-1300°F).

Injection

- Injection System: Transfering the molten aluminum to the shot sleeve of the die casting machine. The machine applies high pressure (usually ranging from 100 to 200 MPa) to force the molten metal into the die cavity at high speed.

- Filling: The metal fills the die cavity in a matter of milliseconds. The high pressure and speed ensure that the metal reaches all the intricate details of the mold, resulting in a well-defined part.

Solidification

- Cooling: After metal injecting into the die, it begins to cool and solidify. The die can accelerate the solidification process with cooling channels. This is important to minimize cycle time and ensure consistent part quality.

- Cycle Time: The time it takes for the metal to solidify depends on the part thickness and the cooling system. Typically, it ranges from a few seconds to a minute.

Ejection

- Opening the Die: After the part solidifing, the die will open. The ejector pins in the ejector die push the part out of the mold cavity.

- Trimming: Sometimes, excess material such as flash or runners may need to be trimmed off the part.

Post-Processing

- Inspection: Workers inspect the part for defects such as porosity, inclusions, or surface imperfections. They may use non-destructive testing methods like X-ray inspection or ultrasonic testing for critical parts.

- Secondary Operations: Depending on the application, the part may undergo additional processes such as machining, heat treatment, or surface finishing (e.g., painting, plating) to meet the final specifications.

Quality Control and Recycling

- Quality Control: Throughout the process, strict quality control measures are in place to ensure consistency and adherence to specifications. Statistical process control (SPC) can monitor critical parameters.

- Recycling: Workers collect and recycle any scrap or defective parts. Since aluminum is highly recyclable, they can reuse the recycled material in the melting process, which reduces waste and cost.

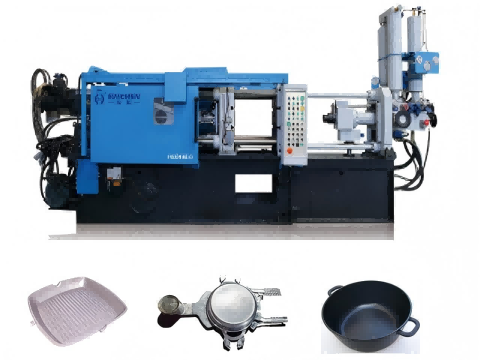

How HAICHEN’s Solution Works in Real Production

HAICHEN die casting machines are known for stability and precise control. They give reliable support in every step above. Here is an example making an aluminum fry pan.

- Project and Challenge

- HAICHEN Solution and Process

Project and Challenge

A customer needed to make a deep aluminum fry pan, 28 cm wide and 7 cm tall. The pan had thin walls (4 mm bottom, 2.8 mm side) and needed a smooth surface. It also had to heat evenly and be made in large numbers very fast.

HAICHEN Solution and Process

- Machine and Mold Work: We used a HAICHEN 650-ton cold chamber machine. Its strong clamping system kept the large mold steady during injection. HAICHEN engineers helped improve the mold’s gate design, using a center gate for smooth filling.

- Precise Injection Control: We used the machine’s 3-stage injection system. First, slow speed to seal the shot sleeve. Then, high speed to fill the thin walls. Finally, high pressure to pack the metal. This reduced cold marks and shrinkage holes.

- Accurate Temperature Control: The machine’s multi-zone mold temperature controllers cooled the bottom and sides of the mold evenly. This kept the pan’s size consistent and made it strong.

With the HAICHEN solution, the pan’s cycle time stayed under 45 seconds. The product yield was over 98.5%. The wall thickness was even, and the surface was good enough for non-stick coating later. The customer’s production efficiency improved a lot.

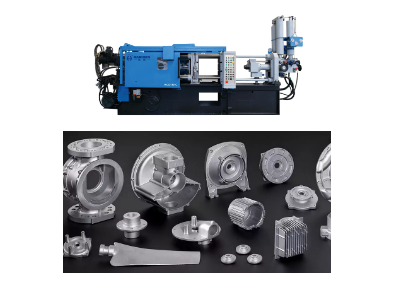

Die Casting machine supplier: Haichen Machinery

Haichen Machinery is a Chinese company specializing in the manufacturing and supply of aluminum cold chamber die casting machines, hot chamber die casting machines and related equipment. We offer a range of die-casting solutions, including cold chamber die casting machines, which are commonly used for aluminum, magnesium, and other non-ferrous alloys.

Aluminum pressure die casting is a highly automated and efficient process, making it suitable for high-volume production. It offers advantages such as high dimensional accuracy, good surface finish, and the ability to produce complex geometries.