The purpose of a conveyor in die casting is to automate part transfer, improve efficiency, and ensure safe handling of castings.

In the die – casting industry, conveyors play a crucial role in optimizing the production process and ensuring efficiency.

From the moment a part is cast to its final packaging, conveyors facilitate seamless material handling, reducing manual labor and increasing throughput.

A conveyor system is designed to transport cast parts from the die – casting machine to various post – processing stations, such as trimming, inspection, and packaging.

Whether it’s moving heavy components or delicate finished products, conveyors are integral to maintaining a smooth and uninterrupted workflow.

This article will explore the key purposes of conveyors in die – casting and how they contribute to the overall production workflow.

The purpose of a conveyor in die casting

- Efficient Part Handling

- Streamlined Production Workflow

- Quality Control and Inspection

- Integration with Post-Processing Stations

Efficient Part Handling

Conveyors are essential for the efficient handling of cast parts. They automate the process of moving parts from the die casting machine to downstream operations, reducing the need for manual labor and minimizing the risk of damage to the parts during handling.

Haichen Practice: In Haichen’s integrated solutions for kitchenware manufacturers, after the 280X70 aluminum pot is demolded from the die-cast mold, it is automatically received by a custom-designed high-temperature resistant mesh belt conveyor. The conveyor belt speed is synchronized with the die-casting machine’s cycle time, avoiding scratches or deformation that may be caused by manual handling, and directly sending the pot into the forced cooling channel, laying the foundation for efficient production.

Streamlined Production Workflow

By integrating conveyors into the die casting process, manufacturers can create a streamlined production workflow. Conveyors smoothly transport parts through the production line, eliminating bottlenecks and boosting efficiency.

Quality Control and Inspection

Conveyors incorporate inspection stations where quality controllers visually examine cast parts or automated systems perform defect detection. This allows for early detection of defects and ensures that only high-quality parts proceed to the next stage of production.

Integration with Post-Processing Stations

Engineers design conveyors to connect directly with trimming units, CNC machining centers, and automated packaging lines. This integration ensures that parts move efficiently through each stage of the production process, reducing cycle times and increasing throughput.

Types and Design of Conveyors

- Horizontal Conveyors

- Inclined Conveyors

- Curved Conveyors

- Custom Design

Horizontal Conveyors

- Suitable for short-distance transportation.

- Advantages and application scenarios.

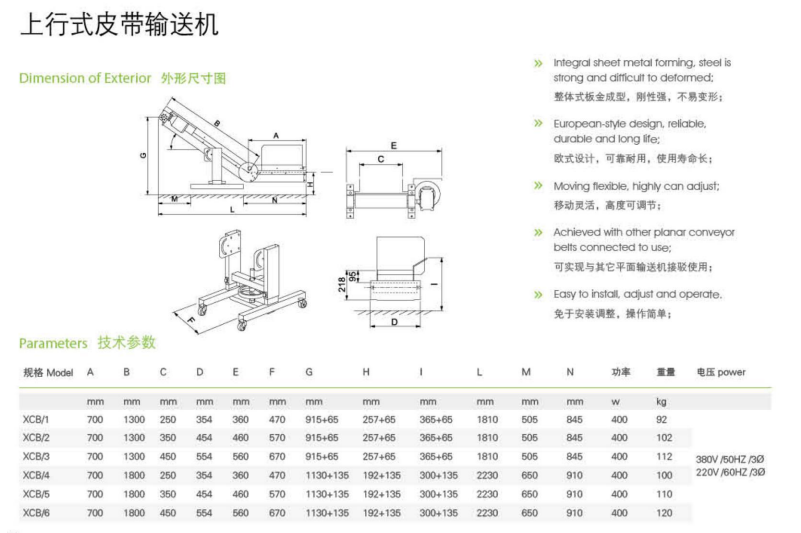

Inclined Conveyors

- Ideal for multi-level production layouts.

- Advantages and application scenarios.

Curved Conveyors

- Suitable for complex layouts and space optimization.

- Advantages and application scenarios.

Custom Design

- Tailoring conveyor systems to meet specific production needs.

- Enhancing production flexibility and adaptability.

Maintenance and Optimization of Conveyors

- Importance of Regular Maintenance

- Optimizing Conveyor Performance

- Energy Efficiency and Environmental Impact

Importance of Regular Maintenance

- Inspecting wear and tear on the conveyor.

- Timely replacement of damaged components.

Optimizing Conveyor Performance

- Adjusting conveyor speed and load.

- Utilizing advanced sensors and control systems.

Energy Efficiency and Environmental Impact

- Implementing energy-efficient motors and drive systems.

- Reducing energy consumption and environmental impact.

Safety and Reliability of Conveyors

- Safety Features

- Enhancing Reliability

Safety Features

- Emergency stop buttons and safety guards.

- Preventing injuries to operators and damage to equipment.

Enhancing Reliability

- Using high-quality materials and components.

- Ensuring long-term stable operation and minimizing downtime.

HAICHEN: Your Partner in Die Casting Solutions

At HAICHEN, we specialize in manufacturing advanced die casting machines designed to meet the highest standards of precision and reliability. Our machines integrate high-efficiency conveyor systems that handle parts smoothly and consistently. Whether you are producing automotive parts, aerospace components, or other high-precision products, HAICHEN offers the tools and expertise to help you achieve your production goals.

Why Choose HAICHEN?

- Advanced Technology: Our die casting machines are equipped with state-of-the-art control systems and precision components to ensure high-quality production.

- Custom Solutions: We offer tailored machine configurations to meet specific production needs, including conveyor design, material type, and production volume.

- Quality and Reliability: HAICHEN machines are built to the highest standards of quality and reliability, ensuring consistent performance and minimal downtime.

- Comprehensive Support: Our commitment to customer satisfaction includes comprehensive after-sales support, technical assistance, and maintenance services.

Conveyors are integral to the die casting process, providing efficient part handling, streamlined production workflows, quality control, and seamless integration with post-processing stations.