The purpose of servo motor in die casting machines is to ensure precision, energy efficiency, and consistent part production.

The servo motor in a die-casting machine controls injection speed and pressure with extreme precision.

By managing these parameters, it keeps the mold movement synchronized, so cavities fill cleanly and parts meet specifications.

The improvement translates into better surface finishes, less scrap, and lower kilowatt-hours per kilogram of metal processed.

Working Principle and Technical Characteristics of Servo Motors

Definition and Basic Structure

A servo motor translates a voltage instruction into mechanical travel with sub-degree repeatability.

The equipment consists of a rotor with a field magnet, a sub-micron extensional encoder, a compact control board, and a gearbox yielding high auger torque at reduced input shaft speed.

By constantly sampling movement rates and orientation, the assembly maintains a recurrent control loop that clashes with error in the milliseconds.

Workflow

- Signal Input: The digital master board forwards a modulated pulse code, toning pulse width to designate shaft rotation angle or velocity demand.

- Torque Generation: The electro-metal coils modulate RMS current to synthesize the exact magnetic pull, making the rotor align with a nip curve torque at preset amperes.

- Real-time Feedback: The encoder emits square waves, pulse per millimeter, quantifying the angle error in micro-radians. The control node subtracts this degree from the ask and generates a dip proceed.

- Dynamic Correction: The main micro executes the dip, rewrites management RMS and templates digital pulse width, and closes the error loop, fully within fifty milliseconds.

The purpose of servo motor

- Precision Alongside Control

- Energy Efficency

- Contract of speed and die energy responsiveness

- Consistency And Repeatability

- Reduced Servicing

- More Green

Precision Alongside Control

They have a major importance in providing precice energy control to the die casting process.

Motors work to control the position, speed, and movements of the machine.

Without this level of precision, it would be impossible to achieve repeatable part fabrication in terms of surface texture, dimensions, and finishing touches.

Energy Efficency

Their energy savings is one of the most notable advantages of servo motors.

Other hydraulic systems operate continuously, but these motors only work when movement is needed.

In the die casting machine, this gives room for a lot more energy savings.

Contract of speed and die energy responsiveness

These motors provide the best speeds along with incredibly fast response times. After that, this allows the die casting machines to increase pace of production.

When conditions change, the motors can quickly adapt to speed changes. This leads to more efficient production cycles.

Consistency And Repeatability

The servo motor’s application guarantees that die casting will be performed with consistency and repeatability.

This is particularly valuable for mass production in which every single component has to pass rigorous testing and quality evaluation.

Reduced Servicing

Operators of die casting machines will benefit from reduced servicing costs and downtime because servo motors are less maintenance intensive when compared with hydraulic systems.

More Green

Servo motors are lesser waste produced than other motors, making them more efficient and environmentally friendly for die casting operations.

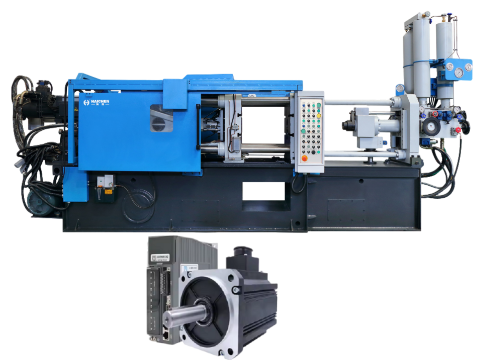

HAICHEN Servo System: Engineering Practice from Precision Control to Process Closure

HAICHEN deeply integrates servo motor technology into its complete die casting solutions. The value goes beyond simple energy saving and speed control; it enables predictable, repeatable, and stable production processes.

- System-Level Integration

- Case Study: Solving Challenges in New Energy Battery Pack Casting

- Measurable Results

System-Level Integration

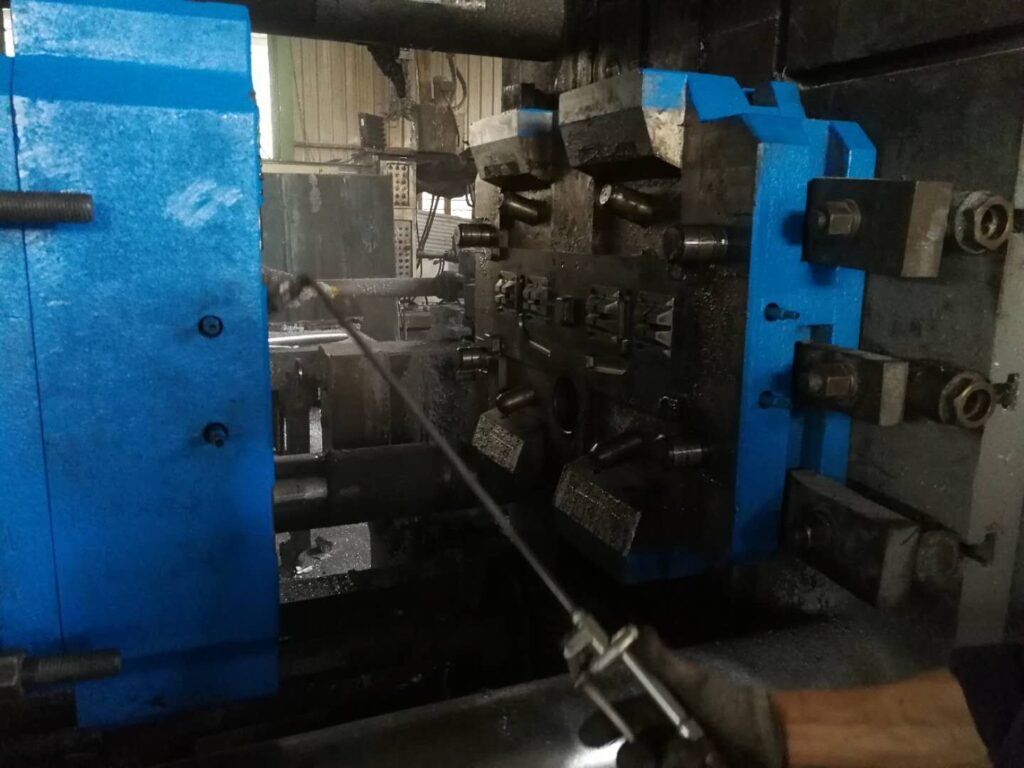

HAICHEN’s servo system works closely with the main machine controller, sensors, and database. It not only follows set injection profiles but also makes millisecond-level adjustments based on real-time feedback (like material position, mold temperature). This creates an adaptive, closed-loop process control, ensuring highly consistent conditions for every shot.

Case Study: Solving Challenges in New Energy Battery Pack Casting

A customer used a HAICHEN 1200T machine to make large, thin-wall battery pack housings. Traditional hydraulics were too slow to respond with pressure at the end of fill, causing low density in some areas. HAICHEN provided a high-response dual servo pump system. One pump was for high-speed filling, the other for instant ultra-high intensification, with smart software managing the switch. This kept intensification time stable under 25 milliseconds.

Measurable Results

This solution raised the product’s internal quality (X-ray inspection pass rate) from 93% to over 99.5%. Also, the servo system’s efficient energy management cut the average power use of that hydraulic unit by about 40%. This demonstrates the dual advantage of HAICHEN’s servo solution: pushing process limits and lowering overall operating costs.

HAICHEN: Manufacturer of Die Casting Machines

Casting Die Machines are manufactured using the latest technologies like servo motors which HAICHEN takes pride in.

To guarantee that all die casting works are performed to the highest level, we produce machines that work with unparalleled precision, efficiency, and reliability.

HAICHEN has established an unrivaled reputation because, with their unwavering focus on innovation and quality, die-casting manufacturers across the globe looking to produce high-grade components can rely on them as key partners.

As mentioned above, die casting machines require servo motors because the enable greater control over energy savings, and reliability, enhancing the entire casting process.

They are integral to high-performance and high-quality castings while reducing waste, thus serving die casting operations.