Tank capacity for die casting machines is the volume of hydraulic oil that can be held in the die casting machine tank, usually in liters (L).

The die casting machine tank capacity is directly related to machine lubrication, cooling, stability, energy efficiency. And with productivity, environmental impact, cost-effectiveness, process and quality control.

Selection of die-casting machine tank capacity should base on the specific model of the machine. Also with working conditions, hydraulic system requirements, and safety factors such as comprehensive consideration. To ensure that the tank capacity not only meets the work requirements but also has sufficient safety margins.

- Impact of Tank Capacity on Die Casting Machine Performance

- How to choose the die casting machine tank capacity

- Process parameters

Impact of Tank Capacity on Die Casting Machine Performance

- Lubrication and cooling

- System pressure and stability

- Continuity of operation

- Energy efficiency

- Environmental impact

- Process Parameter Control

- Quality control

- Die casting machine specifications

Lubrication and cooling

The oil in the tank is responsible for lubricating and cooling the moving parts of the die casting machine. Adequate oil volume ensures stable oil temperature during operation of the system and avoids overheating of components, thus reducing wear and prolonging component life.

System pressure and stability

the tank capacity needs to be large enough to maintain stable pressure in the hydraulic system. When the hydraulic oil circulates in the system, the larger tank can reduce the change of oil temperature and keep the system pressure constant, so as to ensure the stability of the die casting process .

Continuity of operation

A larger tank reduces the number of refuelings and improves the continuity of production. During long production runs, this reduces downtime due to refueling, increasing productivity.

Energy efficiency

Fuel tank capacity affects energy efficiency. A larger fuel tank maintains fuel temperature better and reduces energy consumption, as fluctuations in fuel temperature can lead to a decrease in energy efficiency.

Environmental impact

Energy consumption and environmental impact can be reduced by maintaining the oil in the optimal temperature range.

Process Parameter Control

Tank capacity is critical to maintaining process parameters in the die casting process, such as fill rate, pressure and cycle time, which directly affect product quality.

Quality control

Oil tank capacity is also related to quality control during the die casting process. For example, by monitoring and adjusting the oil temperature in real time, product defects can be reduced and product quality can be improved .

Die casting machine specifications

Different models of die casting machine oil tank capacity is different. Different machine brand manufacturers have different design drawing. For example, some die casting machine oil tank capacity may be 3600 liter.

How to choose the die casting machine tank capacity

- Tonnage of die casting machine

- Hydraulic System Requirements

- Oil quality

Tonnage of die casting machine

The larger the tonnage of the die casting machine, the more oil required for its hydraulic system, so the tank capacity needs to be increased accordingly. For example, a larger die-casting machine may require a larger tank to ensure an adequate supply of hydraulic oil.

Hydraulic System Requirements

Hydraulic systems require sufficient oil for lubrication and cooling, and tank capacity must ensure that the oil can be circulated and cooled efficiently throughout the production cycle.

Oil quality

Tank capacity also relates to the quality of the oil. A larger tank will better maintain the cleanliness and temperature of the oil, thus extending the life of the oil and reducing maintenance costs.

Process parameters

- Neglecting the actual production demand

- Oil tank capacity is too small

- Excessive Fuel Tank Capacity

- Oil circulation and cooling are not considered

- No room for expansion

Process parameters in the die casting process, such as filling speed, pressure and cycle time. They are all directly affect product quality. The tank capacity needs to be able to support the stable operation of these parameters.

The following are some common misconceptions that should be avoided when choosing the capacity of a die casting machine tank:

Neglecting the actual production demand

When choosing the tank capacity, not only the tonnage of the die casting machine should be considered, but also the actual production demand, including the production volume, die size and complexity and other factors .

Oil tank capacity is too small

Too small a tank capacity may lead to high oil temperature, oil oxidation and sludge generation, affecting the performance and life of the hydraulic system.

Excessive Fuel Tank Capacity

Excessive fuel tank capacity may result in unnecessary cost increases and wasted space.

Oil circulation and cooling are not considered

The tank capacity needs to ensure that the hydraulic oil has enough circulation and cooling space to maintain a stable oil temperature and prevent the oil from overheating.

No room for expansion

When selecting tank capacity, a certain amount of room for expansion should be reserved to accommodate possible future production expansion or process changes.

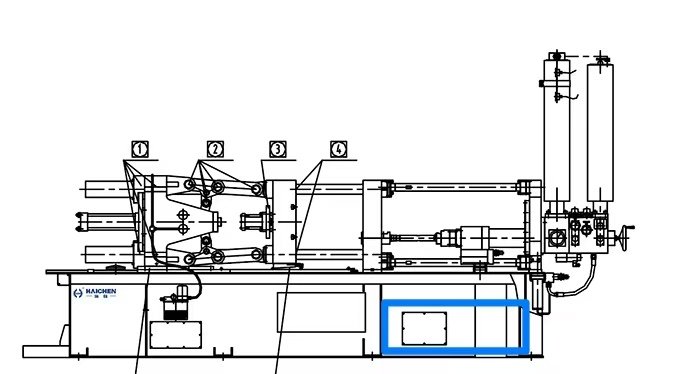

Haichen die casting machine tank capacity

Haichen is one Chinese die casting machine manufacturer. We produce durable and high precision cold chamber and hot chamber die casting machines with more than 10years production experience.

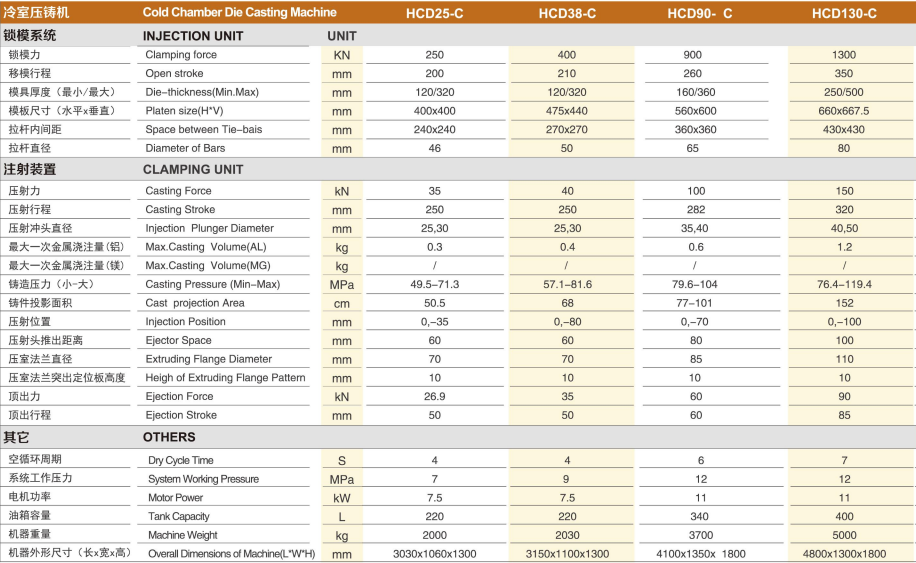

Below is the parameter table of our Haichen brand cold chamber die casting machines. And you can check and find other machine tonnage in our full range of Haichen catalog.

Hot chamber die casting machine and cold chamber die casting machine, oil tank also different.

You can check the tank capacity of each of our die casting machines against the table, and you can also select a die casting machine with different tank capacity according to your product design requirements. If you need, please leave us a message, we will be glad to reply you quickly.