Components used in the automotive, aerospace, consumer electronics, and hardware industries require high-precision thin wall metals. Zinc die casting is used to manufacture these parts because it has the capability of making complex parts with high accuracy.

As with all die casting methods, zinc die casting is a multistep process that combines the steps of melting, molding, and molding molten zinc alloy into the desired shape under high pressure.

Zinc die casting is quite popular because it is cost-effective and has high productivity, excellent accuracy, and remarkable part quality with superb surface finishes.

This article will explore the various uses of zinc die casting and why it is a preferred choice for many industries.

What is zinc die casting used for?

Zinc die casting is a versatile manufacturing process used across various industries for producing high – precision, lightweight, and durable components.

It is particularly popular in the automotive sector for creating intricate parts such as engine mounts, brake components, and transmission housings, where strength and weight reduction are crucial.

In the electronics industry, zinc die – cast parts are used for housings and enclosures due to their excellent dimensional stability and surface finish.

Zinc die casting is also widely used in the consumer goods sector for items like door handles, locks, and decorative fittings, thanks to its ability to produce complex geometries with tight tolerances.

Additionally, the aerospace industry benefits from zinc die – cast parts for their high strength – to – weight ratio and corrosion resistance, which are essential for aircraft components.

Automotive Industry

Functional Components

Die casting in zinc alloy provides automakers with components for key automobile systems with advanced performance. These systems are:

- Engine Components: Parts such as mounts, brackets and housings are critical from an engine’s functionality perspective. And are often made from zinc die cast parts because of their exceptional strength and durability.

- Interior and Exterior Trim: Zinc die cast is capable of producing high quality trim parts such as fuel and service doors as well as high quality and durable handles, precision windows and dashboard components. These parts have excellent corrosion resistance as well as a high quality finish.

Advantages

- High Strength: Zinc alloys offer strength and rigidity needed for automobile components.

- Precision: Zinc die casting ensures parts are made with exact precision. And therefore less time and costs are incurre during assembly.

- Corrosion Resistance: Parts made of zinc and exposed to harsh conditions are beneficial as zinc naturally has corrosion resistance.

Consumer Electronics

Enclosures and Housings

In the case of the enclosures and housings of consumer electronics, Zinc die cast parts are use widely. These parts provide:

- Strength and Durability: Everyday used electronic devices made of zinc alloys are able to provide strength and durability.

- Aesthetic Appeal: Zinc die cast parts improves the quality and electronics devices and ensures the high – qualityness surface finish.

Advantages

- Precision: Complex shapes and modern design of the electronic devices, thin – walled parts of areable to produced with zinc die cast.

- Lightweight: Portable electronic devices are usually made of zinc, as it is stronge and relativly lightweight for other metals.

Hardware and Tools

Fasteners and Components

Zinc die – cast parts are widely use in the production of hardware and tools. These include:

- Screws and Bolts: Zinc – plated fasteners offer excellent corrosion resistance and a high – quality finish.

- Tool Handles: Zinc die – cast handles provide a comfortable grip and durability.

Advantages

- Corrosion Resistance: Zinc’s natural resistance to corrosion makes it ideal for hardware exposed to outdoor elements.

- Cost – Effective: Zinc die casting is a cost – effective solution for producing high – volume hardware components.

Medical Devices

Precision Components

Zinc die – cast parts are use in the medical industry for producing precision components. These include:

- Surgical Instruments: Components such as handles, clamps, and other surgical tools benefit from the precision and strength of zinc die – cast parts.

- Medical Equipment Housings: Zinc die – cast housings provide durability and a high – quality finish for medical devices.

Advantages

- Precision: The high – precision nature of zinc die – cast ensures that medical components meet stringent quality standards.

- Biocompatibility: Zinc alloys can be engineere to be biocompatible. Making them suitable for use in medical applications.

Comparing Aluminum/Magnesium Die Casting: Scenario-Based Selection Guide

| Parameters | Zinc Die Casting | Aluminum Die Casting |

| Density (g/cm³) | 6.6–7.2 | 2.7 |

| Tensile Strength (MPa) | 250–400 | 160–310 |

| Thin-Wall Capability (mm) | 0.3 | 0.8–1.2 |

| Mold Life (Times) | >750,000 | 80,000–100,000 |

| Applications | Precision small parts, complex thin-walled parts | Lightweight large structural parts |

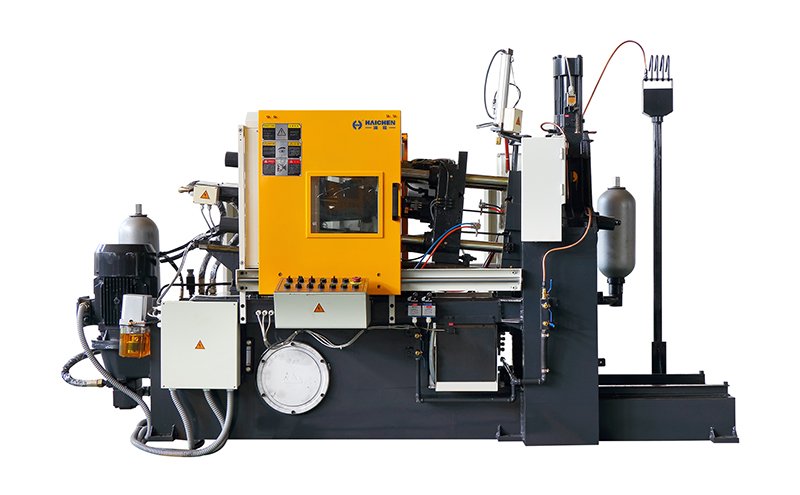

HAICHEN: Your Partner in Die Casting Excellence

At HAICHEN, we are industry leaders in manufacturing die casting machines of outstanding quality that are extremely precise. Our machines are equip with advanced features that guarantee constant and high-quality production. From automotive and medical parts to consumer and electronic hardware, all can be cater at HAICHEN.

Haichen Zinc Die Casting – Medal Production

Precision Medal Manufacturing:

We have over ten years of experience in zinc alloy medal and commemorative coin casting.

For example, we have configured a 90-ton hot chamber die casting machine, using a 4-cavity mold to efficiently produce zinc alloy round medals with a diameter of 70 mm and a thickness of only 1.4 mm.

Haichen’s precision injection control and temperature management system ensures that every medal has a clear design and a bright surface, meeting the demanding requirements of high-end gifts and souvenirs.

High-End Automotive and Industrial Parts:

Our zinc die casting solutions also serve industries with stringent performance requirements.

Haichen ensures that its products meet 100% automotive safety standards through optimized mold design (using high-quality mold steel with a special cooling channel layout) and stable injection processes.

Engineering Support and Defect Prevention:

Haichen understands that the success of zinc die casting begins with excellent mold and process design.

We adopt advanced engineering methods, using mold flow analysis software for simulation during the mold development phase.

This can help predict the filling pattern of molten metal, optimize the gating system and venting, and effectively prevent potential defects such as porosity, cold shuts or incomplete filling before putting it into actual production, saving customers valuable trial molding time and costs.

Zinc die casting is extremely popular due to its versatility and reliability. It is used in the manufacturing industry because it can be relied upon to produce parts that need to be strong, precise and are needed in corrosive environments.