Zinc medals are applicable to a wide range of instances from sporting activities to corporate, commemorative events, and personal commemorations.

Zinc alloys offer a variety of advantages including low weight, high strength, ease of casting, and good surface treatment, making them ideal for medal production. Zinc medals are applicable to a wide range of instances from sporting activities to corporate, commemorative events, and personal commemorations.

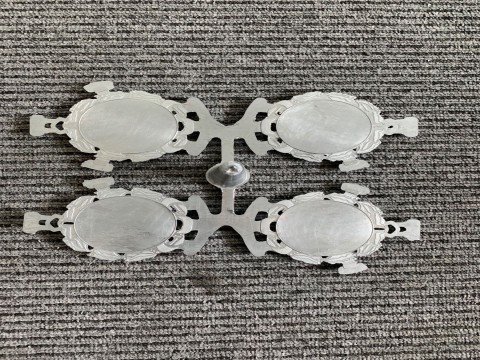

In terms of manufacturing processes, zinc alloys medals are either die cast or die struck cast. High precision and complex medal designs can be created using the die cast method, whereas mold casting is preferred for medals that need fine surface treatment. Zinc alloy’s low melting point and excellent fluidity guarantees that the mold can be filled completely, capturing all the details of the medal.

Zinc alloys are very suitable, applicational for making various types of medals. Due to its low cost, high durability, easy casting and processing. The following are the 5 common kinds suitable for making with zinc alloy:

- Sports medals

- Commemorative medals

- Customized medals

- Children’s medals

- Corporate event medals

Zinc alloy medals kind: Sports medals

Zinc alloys often use to make medals in sports competitions, such as gold, silver and bronze medals used in marathons, sports games and other events. These medals are usually highly durable and lightweight. They can decorate by electroplating to enhance their appearance and collection value.

Low melting point and high fluidity

The melting point of zinc alloy is only 385 ° C, much lower than that of copper (1083 ° C) or silver (961 ° C), resulting in lower energy consumption and minimal mold wear during die-casting. Its high fluidity can fill complex molds, achieve fine textures (such as reliefs and hollows), and perfectly present details such as event logos and landmark buildings.

Surface treatment compatibility

Zinc alloy substrates can enhance their texture through processes such as electroplating (real gold/silver/imitation gold), spraying, and polishing. For example, if the medal is required to have a “soft luster and no fingerprints”, zinc alloy can meet this standard after coating treatment, and the coating has strong adhesion and is not easy to peel off.

Commemorative medals

- Excellent casting performance

- Diversity of surface treatment

Zinc alloys are also commonly used to make commemorative medals, such as medals for commemorative events, company celebrations, or personal achievements. These medals are usually beautifully designed. They can preserve for a long time, and have a certain collection value.

Excellent casting performance

Zinc alloy has a low melting point (385-470 ℃), good fluidity, and can accurately fill mold details. It is suitable for making complex three-dimensional shapes (such as reliefs, hollows, thin-walled structures) and achieving high-precision pattern presentation. In contrast, materials such as copper and aluminum are prone to porosity or incomplete filling under the same process.

Diversity of surface treatment

It can be highly polished to achieve a smooth mirror effect.

Compatible with electroplating (gold/silver/antique copper, etc.), baking paint, imitation enamel and other processes to meet different visual needs.

Strong adhesion of electroplating and better color durability than aluminum alloy (aluminum alloy electroplating is prone to peeling off).

HAICHEN Practice of zinc alloy medal making

HAICHEN die casting machines offer high stability and precise control. They help solve many challenges in the zinc door handle production process.

Zinc alloy medal request

A door handle maker wanted to raise the yield rate for chrome plating on a high-end product line. They also wanted to lower the failure rate in strength tests due to internal pores.

HAICHEN’s Process Analysis and Machine Solution

HAICHEN engineers found the root cause: unstable injection speed and slow intensifier response on the old machine. They suggested a new HAICHEN servo die casting machine. It has a precise injection control system and real-time feedback.

Process Optimization and Parameter Setting

For the zinc door handle production process, they set a slower slow-shot speed for smooth air venting. They set a faster start point for fast-shot and higher final intensification pressure for dense filling.

Results Achieved

After the change, the casting surface got much better. This gave an excellent base for plating. The chrome plating yield rate went up by 18%. Also, the internal quality became stable. The strength test pass rate went above 99.5%. Overall production efficiency improved.

Customized medals

- Excellent liquidity and low melting point

- Dimensional stability and tolerance control

Due to its strong plasticity, zinc alloy is suitable for making medals with various complex designs, including 3D designs and personalized patterns. This property makes zinc alloy an ideal choice for customized medals.

Process adaptability: Precision casting and complex design implementation

Excellent liquidity and low melting point

The melting point of zinc alloy is only 385 ° C (much lower than the 1083 ° C of copper), and with high fluidity, it can perfectly fill the fine texture of the mold, achieving complex designs such as relief and hollowing (such as the fine patterns of Asian Games medals).

Take an example, the medals of the Hangzhou Asian Games medals. They are made of zinc alloy substrate electroplated with precious metals, with a surface texture clarity of micrometer level.

Dimensional stability and tolerance control

The solidification shrinkage rate is less than 0.7%, ensuring the consistency of medal size during mass production (diameter error ≤± 0.1mm), avoiding later mechanical processing, and shortening the construction period by 15-30%.

Haichen is a manufacturer of medal die casting machine.This machine to make medals and mainly can produce products as follow: challenge coins, lapel pins, medals, belt buckles, key chains, police badges, dog tags, cufflinks, patch and poker chips.

With durable machine running performance and good pre-sales, in-sales and after-sales service. Haichen medal making machine has been exported to many countries. We can provide you with professional advice and solutions, including how to cast medals, working principles of casting machines. Our medal making machine has helped many factories succeed through high efficiency production.

Children’s medals

- Balance between lightweight and safety

- Corrosion resistance and surface treatment advantages

- Adapt processing performance to complex designs

It is also commonly used to make children’s medals due to its lightness and durability, such as honor medals awarded in kindergartens or school activities.

Balance between lightweight and safety

The density of zinc alloy is 6.5-7.2 g/cm ³, which is between aluminum alloy (2.7 g/cm ³) and brass (8.4-8.7 g/cm ³). This feature gives the medal a metallic texture while avoiding accidental injuries (such as smashing) to children while wearing or playing due to excessive weight.

Comparative analysis: Copper medals have a high density, aluminum medals are easily deformed, and zinc alloys achieve a balance between weight and structural strength.

Corrosion resistance and surface treatment advantages

Zinc forms a dense basic zinc carbonate film in room temperature air, which can prevent further oxidation. Combined with electroplating processes such as gold/silver plating, zinc alloy medals can maintain their luster for a long time, and the surface coating has strong adhesion and is not easily peeled off.

Adapt processing performance to complex designs

Zinc alloy has a low melting point (385-470 ℃), good fluidity, and is suitable for die-casting molding. It can precisely manufacture details such as reliefs and hollows of medals, meeting children’s needs for cartoon shapes and text patterns.

Corporate event medals

- High precision molding capability

- Compared to copper or stainless steel

They are also suitable for employee rewards or team honors in corporate activities. The company logo and text can be customized to reflect the company’s brand image.

High precision molding capability

Zinc alloy has a low melting point (generally between 375-390 ° C), excellent flowability (thermal conductivity of 104.7-116 W/m · K), and can perfectly replicate complex mold details, achieving high-precision designs such as relief and hollowing.

Compared to copper or stainless steel

zinc alloy is easier to achieve thin-walled structures (such as 8.6mm thickness at the edge of the medal), reducing weight while maintaining strength, meeting the three-dimensional requirements of the medal’s “highest pattern 9.5mm”.

Zinc alloy has become an ideal substrate for corporate event medals due to its low-cost precision casting capability, rich surface decoration potential, and reliable environmental adaptability.

Haichen zinc alloy medal die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine.They have durable and highly precise features. Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

Haichen have rich experience of manufacturing many kinds of zinc medals as per each customer’s specific demand. We can also supply full production line including zinc alloy medal making machine, medal molds, auto ladle, auto sprayer and other necessary auxiliary equipment.