To produce zinc pipe fittings, specialized machines known as zinc pipe fitting making machine are used.

These machines cope with the exceptional characteristics of zinc for its exact and uniform machining throughout the process.

Zinc pipe fitting manufacturing machinery consists of several functional units: melting furnaces, die casting sets, and post-processing equipment which provide strong fittings.

This article focuses on the various types of machinery for production of zinc pipe fittings and HAICHEN, the leading manufacturer of die casting machines, provides cutting edge technology solutions to maintain quality and efficiency in production.

Following are some machines that are frequently utilized in the production of zinc pipe fittings:

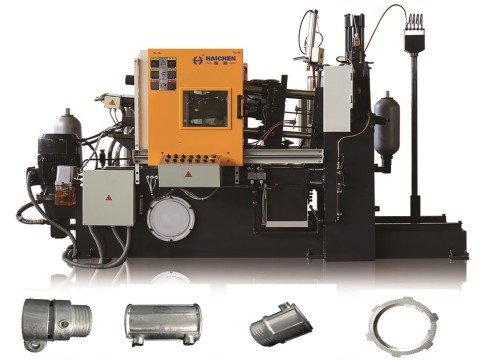

Die Casting Machine

In the production of pipe fittings, with the aid of molds (dies), cast zinc is injected into relevant locations. Substantial amounts of intricately shaped parts are produced by means of screw or rotary die casting machines. These machines are with a guarantee of long-term reliability and minimal maintenance requirements.

Molding Machines

As with every other machine in the system, the molding machine completes the work by shaping the pipe fittings after the molten zinc is injected into the proper mold. These machines are constructed to handle the extreme pressures and temperatures associated with zinc casting. They guarantee that the cavities of the molds are filled uniformly with zinc, thus ensuring that the fittings produced have the least possible defects.

Machining Centers

- Lathes

- Drilling Machines

During the first stages, the surface and dimensions of the zinc pipe fittings are usually cast and rough machined. This initial level of cutting is normally accomplished on one of the computer-controlled machining centers available. Above all these machine tools are equipped with automated systems for loading and unloading the work pieces and are controlled by an onboard computer that executes pre-programmed sequences for drilling, threading, or cutting operations.

Lathes

With the use of lathes, perform the turning operations in the final stages of manufacturing zinc pipe fittings. Lathes enable the creation of threads on fittings, as well as achieving defined geometric cut shapes through rotational cutting.

Drilling Machines

Use drilling machines when creating holes and bores in the zinc pipe fittings for the particular design. With perfect accuracy before, during and after drilling. Above all these machines help achieve the precise dimensions and proper placement required for the integration of the assembly.

Finishing Equipment

- Grinding Machines

- Deburring Machines

Surface treatment systems, polishing machines and vibratory finishing machines are use to enhance the surface appearance. And quality of zinc pipe fittings and their surface is treated before distribution and use.

Grinding Machines

Zinc Pipe fittings undergo surface finishing and polishing to meet the standard of having smooth surfaces. Tight tolerances, as well as the enhanced aesthetic usually associated with the refined appearance.

Deburring Machines

The removal of sharp edges, burrs, and excess materials that often accompany fittings after manufacturing is do using Deburring machines. This stage improves ease of use as well as safety of the fitted pipes.

Inspection and Testing Equipment

The process of producing Zince pipe fittings includes quality control as a core aspect. The pipe fitting has to meet the industrial standards and specifications, which are ensure using Inspection and testing equipment. Such as Coordinate measuring machines (CMMs), hardness testers, as well as leak detection systems.

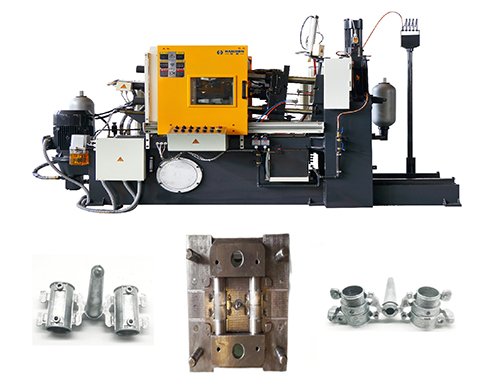

Haichen Zinc pipe fitting making machine

We provide advanced die casting machines and offer solutions tailored to each customer to enhance production of zinc pipe fittings. Machines design to enhance quality, efficiency, as well as sustainability during production are offer at Haichen. Die casting, molding and machining, as well as finishing are all performed by the machines in an interconnected sequence which allows for streamlined production. By choosing HAICHEN, you can trust that you are investing in technology that supports both quality production and environmental responsibility.

HAICHEN Hot Chamber Die Casting Machines in Practical Application

For the actual production of zinc pipe fittings, the appropriate machine tonnage (clamping force) is selection base on part size, weight, and complexity. HAICHEN Hot Chamber Machines, with their stable performance and precise control, are well-suite for these requirements.

Application Example: Production of Serialized Zinc Alloy Elbow Fittings

A professional plumbing components manufacturer needed to produce a series of zinc alloy elbow fittings ranging from 1/4 inch to 2 inches. The parts required smooth internal walls, precise dimensions, standard threads, and the ability to pass high-pressure sealing tests.

For small-sized elbows (1/4″ to 3/4″):

- Machine Selected: HAICHEN 50-ton Hot Chamber Die Casting Machine.

- Suitability: These parts have low net weight and small projected area. The 50-ton clamping force is sufficient to keep the die securely closed against injection pressures (typically 400-600 bar), preventing flash.

- Performance: The machine’s high-response servo injection system enables fast, smooth cavity filling, ensuring complete formation even in thin-walled sections. Its rapid cycle time (exceeding 18 cycles per minute) ensures high-volume output. The stable furnace temperature control maintains metal purity and fluidity, reducing defects like flow marks or cold shuts.

For larger or more complex elbows/tees (1″ to 2″):

- Machine Selected: HAICHEN 90-ton Hot Chamber Die Casting Machine.

- Suitability: Larger parts have a greater projected area and require higher cavity pressure. The 90-ton clamp provides a greater safety margin and can accommodate dies with more complex features or side-cores.

- Performance: The machine’s higher injection force and larger furnace capacity suit heavier castings. Its precise closed-loop injection control allows for programmable multi-stage speed and pressure profiles, optimizing the metal fill pattern. This effectively reduces internal porosity, significantly improving part density to meet stringent hydrostatic pressure test requirements. Machine stability ensures consistent part quality over long production runs.

In conclusion, by employing a combination of these machines and processes. Manufacturers can efficiently produce high-quality zinc pipe fittings that meet industry standards for performance, durability. And reliability in plumbing systems, leveraging the capabilities of zinc pipe fitting making machines.