Hot chamber casting machine materials mainly use zinc alloy, lead alloy, tin alloy and so on.

Hot Chamber Die Casting is a metal die casting process characterized by the injection of molten metal directly into the mold cavity. This process is often used to produce castings of low melting point metals, such as zinc, lead, tin and magnesium alloys.

Hot Chamber Die Casting Machine is mainly used for casting low melting point alloys, such as zinc, lead, tin and magnesium. The characteristic of hot chamber die casting machine is that its injection system (including piston, gooseneck and gate) is directly immersed in molten metal, thus maintaining the high temperature of the metal to reduce heat loss and improve fluidity.

Hot Chamber Die Casting process

- Molten metal: The metal is heated to an appropriate temperature (usually below 700°C) in the hot chamber and kept in a molten state.

- Filling the mold: The piston rises to open the feed port, and the molten metal flows into the runner and into the mold cavity.

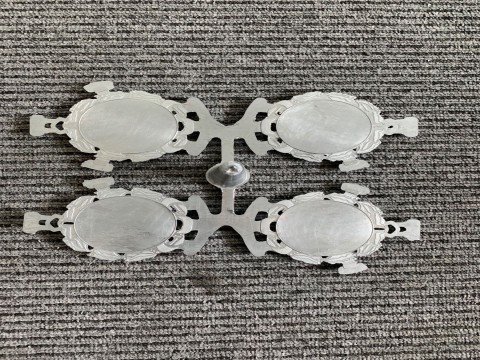

Cooling and solidification: The metal cools and solidifies in the mold, and then the mold opens and the finished product is taken out.- Ejection and cleaning: The casting is pushed out of the mold using an ejector pin, and subsequent trimming and polishing operations are performed.

During the hot chamber die casting process, the molten metal is maintained in a high temperature furnace that is integrated with a hydraulic injection system. When the mold needs to be filled, the hydraulic piston draws the molten metal from the furnace into the mold cavity through the gooseneck. This design ensures that the metal remains at a high temperature during the injection and cooling process, thereby improving the mechanical properties and surface quality of the casting.

Advantage of hot chamber die casting machine

- High productivity

- Suitable for low melting point alloys

- Reduce thermal fatigue

- High degree of automation

- Suitable for thin-walled parts

- High productivity

The hot chamber die casting machine has a very short cycle time, usually 15 times/minute, which makes it extremely productive. For example, some literature mentions that the hot chamber die casting machine can produce up to 500 parts per hour, which is significantly better than the production speed of the cold chamber die casting machine. - Suitable for low melting point alloys:

Hot chamber die casting machines are particularly suitable for processing low melting point metals such as zinc, tin, lead and magnesium. These metals have good fluidity at high temperatures, which makes it easy to fill the mold, while reducing defects caused by long cooling time. - Reduce thermal fatigue:

Because the injection system of the hot chamber die casting machine is immersed in molten metal, its mechanical parts are less subject to thermal shock, thereby extending the service life of the equipment. In contrast, the cold chamber die casting machine needs to transfer the molten metal from the furnace to the injection system, which increases the risk of thermal fatigue. - High degree of automation:

Hot chamber die casting machines are usually equipped with automatic heating systems and automatic pouring systems, which can achieve highly automated operations, reduce manual intervention, and improve production efficiency and consistency. - Suitable for thin-walled parts: Hot chamber die casting machines are suitable for producing thin-walled parts because their fast filling time and high pressure ensure that the molten metal fills the mold evenly, resulting in high-quality surface and dimensional accuracy.

The main advantages of hot chamber die casting machines are their high production efficiency, suitability for low melting point alloys, reduced thermal fatigue, high degree of automation, suitability for thin-walled parts production and optimized weight-to-cost ratio. These features make them an important manufacturing tool in many industrial fields such as automotive, aerospace and consumer electronics.

Hot chamber casting machine materials: zinc alloy

Zinc is the most popular metal when it comes to hot chamber pressure die casting. The zinc casting boasts high strength and hardness along with good wear properties.

Its alloys melt at a relatively low temperature of around 420oC, making it compatible with this process.

It also possesses good electrical and thermal conductivity, making it an exceptional choice for components containing electronic circuitry. Moreover, it has high fluidity in molten form, which improves its dimensional tolerance and allows for the manufacturing of complex geometric features like thin walls.

Common zinc alloys materials include:

- Zamak 3: A general-purpose zinc alloy that is easy to cast and offers excellent dimensional stability. In North America, more than two thirds of zinc die castings use Zamak 3. Example uses include ceiling fans and plumbing components.

- Zamak 2: A slightly stronger and more expensive alloy with added copper content. It often uses to produce tooling for plastic injection molding.

- Zamak 5: A zinc alloy close in composition to Zamak 3 but with greater tensile strength and lower ductility. Popular for products like automotive parts and wheel balancing weights.

Hot chamber casting machine materials: lead alloy

A lead alloy is the primary metal material uses in a hot chamber die casting machine. As its low melting point makes it suitable for this type of casting process where the molten metal continuously supplies from a built-in furnace directly into the mold; other metals often used in hot chamber die casting include zinc and tin alloys.

- Low melting point: The key advantage of using lead alloys in hot chamber die casting is their relatively low melting point, which allows for efficient melting and injection into the mold.

- Application suitability: Lead alloys often uses for applications where high production rates and intricate details are required due to the fast casting cycle possible with hot chamber machines.

Hot chamber casting machine materials: tin alloy

A tin alloy is another normal metal material uses in a hot chamber die casting machine. As hot chamber machines specifically design for metals with low melting points, making tin alloys a suitable choice for this process.

- Low melting point: This is the key characteristic that makes tin alloys ideal for hot chamber die casting, allowing the metal to be easily melted and injected into the mold.

- Applications: Tin alloys are often used to create small, intricate parts due to their good fluidity in the molten state.

Therefore, hot chamber die casting machines mainly use low melting point metals such as zinc, lead, tin and magnesium alloys. These materials widely use in industrial production due to their good casting properties and low cost.

Haichen hot chamber die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine.They have durable and highly precise features. Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.