Choose precision die casting because offering high precision, cost-effectiveness, productivity, material versatility and environmental friendliness.

Precision die casting, with its extremely short forming cycle. Extremely high injection frequency, fully automated process, and the ability to achieve high precision. And low waste in a single forming process. These can achieve significant cost and time advantages in mass production. Therefore, it has become the preferred metal forming process for high-volume manufacturing. Especially in industries such as automobiles, electronics, and home appliances).

We anyalize this topic as consider precision die casting reasons mainly like: its ability to produce high-quality, precise, and complex parts efficiently and cost-effectively. These making a preferred choice for industries requiring high-volume production and stringent quality standards.

- Choose precision die casting reasons

- High Production Efficiency

- Precision and Complexity

- Haichen Precision Die Casting machine supplier

Choose precision die casting reasons

- Dimensional Accuracy

- Cost-Effectiveness of die casting molds

- Cost-Effectiveness of choose precision die casting

- Die Casting is a preferred manufacturing process for several reasons

- Surface Finish of choose precision die casting

- Thin-Wall Parts

- Consistent Quality

- Technological Advancements

Dimensional Accuracy

- The process offers exceptional dimensional accuracy. Achieve tolerances as precise as 0.1 mm for the first 2.5 cm (0.004 inch for the first inch).

- For each additional centimeter, tolerances can be as fine as 0.02 mm (0.002 inch per inch). This precision reduces the need for post-production machining, saving both time and costs.

Cost-Effectiveness of die casting molds

- While the initial setup costs for Precision Die Casting can be high due to the expense of creating the molds. The cost per part decreases significantly as production volume increases.

- This economy of scale makes it an attractive option for producing numerous identical parts. Reducing overall manufacturing costs in the long run.

Cost-Effectiveness of choose precision die casting

- Precision Die Casting is suitable for various metals, particularly aluminum, zinc, and magnesium.

- These materials offer excellent mechanical properties. Such as high strength, durability, and wear resistance. Making them ideal for applications where components need to withstand high stress and harsh operating conditions.

Surface Finish of choose precision die casting

- Die Casting produces parts with smooth surfaces, often reducing the need for additional finishing operations.

- This high-quality surface finish is particularly beneficial for applications. Where aesthetic appeal and surface integrity are important, such as consumer electronics and automotive parts.

Thin-Wall Parts

- The process can create thin-walled parts with walls as thin as 0.75 mm (0.030 inches), which is thinner than what can be achieved with other casting methods like sand casting.

- This capability is particularly beneficial for applications requiring lightweight yet strong components, such as in the electronics and consumer goods industries.

Consistent Quality

- Precision Die Casting ensures consistent quality and repeatability, minimizing waste and rework.

- This consistency is crucial for industries like automotive and aerospace, where component reliability and performance are critical.

Technological Advancements

- Recent advancements in Precision Die Casting technology have focused on improving process control and reducing defects.

- Innovations such as real-time monitoring and advanced cooling techniques have enhanced the quality and reliability of die-cast components.

High Production Efficiency

- Short production cycle and fast turnover

- Suitable for mass production

- High capacity and automation compatibility

- High material utilization and low waste

- One-time die investment with decreasing costs

Short production cycle and fast turnover

Each step of die casting (injection-holding-mold opening) is completed in seconds or even sub-seconds. With an overall cycle time far shorter than traditional casting processes such as sand casting and investment casting.

Suitable for mass production

Once the die is manufactured, tens of thousands or even millions of pieces can be produced continuously in a very short time. The die has a long lifespan and high reusability, significantly reducing the cost per piece.

High capacity and automation compatibility

High-pressure injection and rapid cooling enable high-speed assembly line operations. And easy integration with robots and automated handling systems, further increasing capacity.

High material utilization and low waste

Molten metal rapidly fills the mold cavity under high pressure, achieving near-net-shape forming. This reduces subsequent processing requirements, minimizes die casting material waste, and makes the overall cost more competitive.

One-time die investment with decreasing costs

Die costs account for a large proportion in the early stages, but as production volume increases. The amortization of die costs per unit decreases rapidly. Especially at batch sizes of tens of thousands to hundreds of thousands of pieces, where the cost advantage is most significant.

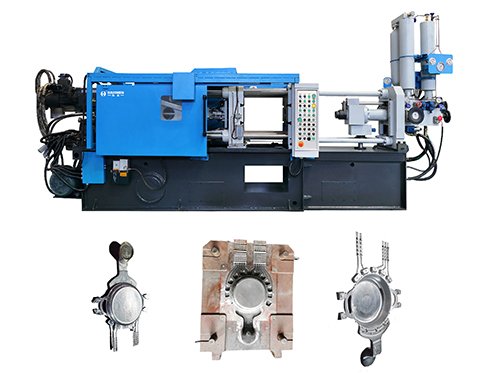

Haichen precise die casting of automotive sensor case

One of Haichen customers who need to make aluminum sensor housings. The parts had thin walls and required a very smooth surface for sealing. Their old machine could not hold tight tolerances, causing leaks. HAICHEN provided a 350-ton cold chamber machine with a high-precision injection system and stable clamping. With this machine, the customer achieved perfect dimensional control and surface quality. Leakage issues ended, and they secured a long-term supply contract.

HAICHEN Machine Advantage for Precision

Our machines are built for precision. Features like digital servo valves, rigid machine frames, and precise temperature control work together. They ensure every shot is the same as the last. This repeatability is the foundation of precision die casting. For manufacturers, it means they can confidently produce complex, high-value parts.

Precision and Complexity

- Extremely High Dimensional Accuracy and Tight Tolerances

- Capable of Achieving Complex Geometries

- Exquisite Surface Quality

- High Repeatability and Batch Consistency

- Precision Die Casting excels at producing complex parts with intricate details and tight tolerances.

- The high-pressure injection ensures that molten metal fills even the smallest mold cavities, capturing fine features and achieving high precision.

- This is crucial for components requiring detailed designs and exact specifications. Such as those used in the automotive and electronics industries.

Extremely High Dimensional Accuracy and Tight Tolerances

- Through high-pressure injection and precision molds, die castings achieve extremely small dimensional deviations. Meeting stringent assembly requirements and significantly reducing subsequent processing costs.

- This precision is particularly critical in industries with extremely high dimensional requirements, such as automotive, aerospace, and electronics.

Capable of Achieving Complex Geometries

- Precision die casting can create complex features such as internal channels, heat dissipation fins, thin walls, sharp corners, and chamfers in a single process, which is difficult to achieve with traditional machining.

- High Design Freedom: Multifunctional structures can be integrated into single components, improving product integration.

Exquisite Surface Quality

Due to the smooth surface of the mold, die castings often possess excellent surface finish, reducing or eliminating subsequent grinding and painting processes.

High Repeatability and Batch Consistency

Once the mold is manufactured, each subsequent part produced maintains almost identical dimensions and quality, making it suitable for mass production with a low scrap rate.

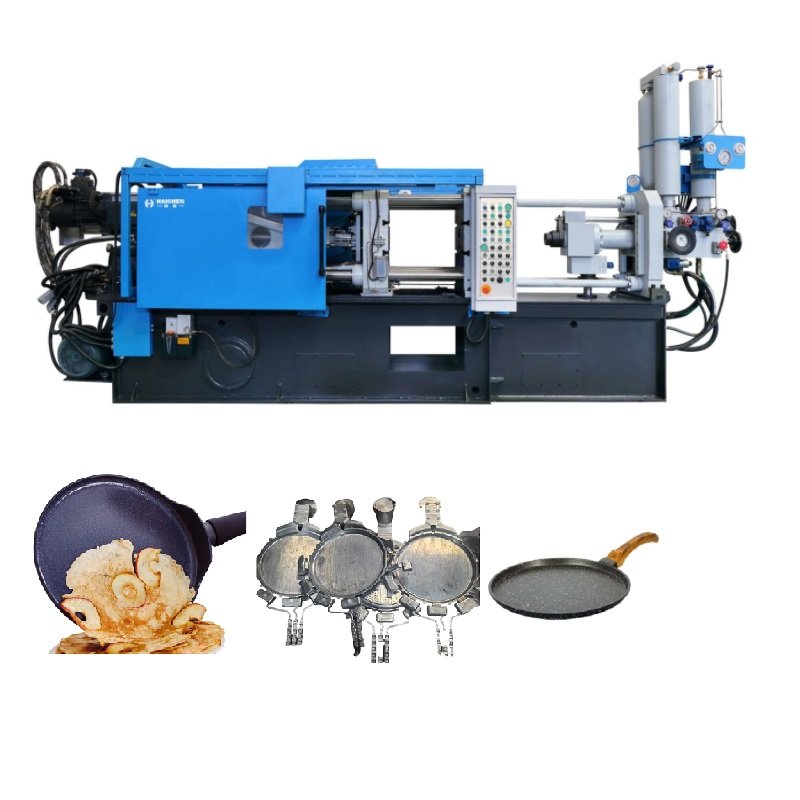

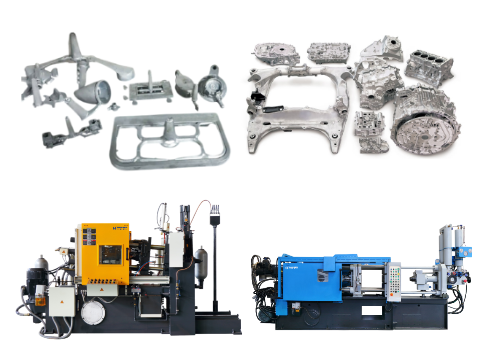

Haichen Precision Die Casting machine supplier

Haichen is a well-known supplier of die casting machines. And it relates equipment, specializing in high-quality, efficient, and reliable solutions for the die casting industry.

Wprovides a variety of die casting machines, including:

Cold Chamber Die Casting Machines: Ideal for aluminum and copper alloys.

Hot Chamber Die Casting Machines: Suitable for zinc, magnesium, and other low-melting-point alloys.

Besides die casting machines, we also supply auxiliary eqiupments. If there is any demand, welcome to consult us.