Furnace is so crucial in die casting because it controls the melting metal temperature, improve energy and cost effective, etc.

The furnace plays a vital role in the die casting process. It is not only responsible for the melting and temperature control of the metal, but also directly affects the quality of the castings.

The furnace is the “thermal heart” of the die-casting process. It not only melts and maintains the metal, but also determines casting quality. Like mold life, and production efficiency through precise and stable temperature control.

Technologies such as PID, dual temperature measurement, and high-efficiency insulation materials are used to minimize temperature fluctuations. Significantly reducing defects, improving consistency, and achieving energy savings—the core requirements of modern die-casting furnaces.

- Furnace function of die casting

- Temperature Control and Consistency

- Energy efficiency and cost effectiveness

- Adapt to the needs of different metals

- Reduce transportation losses

- Support high-quality casting production

Furnace function of die casting

The furnace is the key equipment for melting metal in the die casting process. The metal is heated above the melting point in the furnace to form liquid metal. Which is then it inject into the mold to form the casting.

- Melting

- Holding

- Impurity Control and Metal Purification

- Impact on Cycle Time

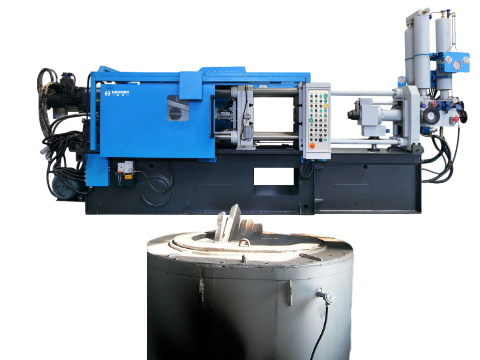

For example, in hot chamber die casting, the furnace directly installs inside the die casting machine. And the metal directly inject from the furnace into the mold. Without the need for an additional transportation process, thereby improving efficiency and reducing heat loss.

Melting

- The furnace is responsible for converting solid raw materials into liquid metal. This is the first step in die casting and the only energy input. Without a reliable melting process, subsequent high-speed injection, filling, and solidification processes are impossible.

- Different alloys (such as aluminum, zinc, and magnesium) require different melting temperatures, and the accuracy of the furnace’s temperature control directly affects the alloy’s fluidity and chemical composition.

Holding

- After melting, the metal must be maintained at the set pouring temperature in a holding furnace to prevent cooling or crystallization before being transferred to the mold. The design of the holding furnace determines the temperature fluctuation range of the metal throughout the cycle, which in turn affects filling integrity and casting dimensional accuracy.

- In hot chamber die casting, the furnace is built directly into the machine, minimizing the distance the metal travels from the furnace to the mold, minimizing heat loss and maximizing cycle speed. 3. Temperature Uniformity and Thermal Efficiency.

- The furnace’s internal heating elements, insulation lining, and temperature monitoring system work together to ensure uniform temperature, preventing localized overheating or cold spots that could lead to metal oxidation, inclusions, or porosity.

- Modern furnaces are also optimized for energy consumption and heat recovery, reducing operating costs while maintaining metal quality.

Impurity Control and Metal Purification

- Deoxidizers, degassing agents, and impurity removers can be added during the melting and holding processes to help remove oxide scale, gaseous matter, and solid inclusions.

- The high temperature environment provided by the furnace is a prerequisite for these chemical treatments to be effective.

- Surface slag is removed through filtration or decantation to ensure the purity of the metal entering the mold.

Impact on Cycle Time

- The furnace’s heating rate and insulation capacity determine the minimum duration of each die-casting cycle. Hot chamber die-casting furnaces can complete the melt-injection-solidification process in approximately 20 seconds, significantly improving the efficiency of large-scale production.

- If the furnace temperature control is unstable, the insulation or preheating time will need to be extended, which will directly slow down the production line.

Temperature Control and Consistency

The furnace is not only responsible for melting the metal, but also must precisely control the temperature of the metal. Too high a temperature can cause the metal to oxidize or degrade. While too low a temperature can result in insufficient fluidity.

- Core Equipment for Melting and Holding

- Why Temperature Control is Critical

- Temperature consistency brings multiple benefits

Therefore, the furnace must be able to stably maintain the required temperature range. That to ensure the quality and consistency of the castings.

Core Equipment for Melting and Holding

- Die casting requires rapidly melting metal and maintaining it at the appropriate liquidus temperature in an extremely short time. The furnace is responsible for achieving the dual tasks of “rapid melting and precise holding,” serving as the heat source for the entire process.

- Common furnace types include electric arc furnaces, induction furnaces, crucible furnaces, and holding furnaces, all of which can maintain the metal’s chemical composition and fluidity at high temperatures.

Why Temperature Control is Critical

- Metal Fluidity and Filling Quality: Metal temperature directly determines its viscosity and fluidity. Insufficient temperature can lead to incomplete filling, defects such as cold shuts and pores; excessive temperature can exacerbate oxidation and cause thermal cracking.

- Solidification Process and Microstructure: Temperature control determines the solidification rate and grain structure, which in turn influences the mechanical properties and surface quality of the casting.

- Mold Life: If the metal temperature provided by the furnace differs significantly from the mold preheat temperature, thermal shock can occur, leading to hard spots and cracks on the mold surface and shortening mold life.

Temperature consistency brings multiple benefits

- Defect reduction: Through PID control and dual temperature measurement technologies, furnace temperature fluctuations can be controlled within ±5°C, significantly reducing defects such as porosity, shrinkage, and thermal cracking caused by temperature fluctuations.

- Improved production efficiency: With stable temperatures, filling and cooling times are more predictable, cycle times are shortened, and overall productivity is increased.

- Energy and cost savings: Precise temperature control reduces overheating and heat loss, improving energy efficiency and reducing operating costs.

- Product consistency: The metal temperature is the same every time it is cast, ensuring repeatable dimensional accuracy, surface finish, and mechanical properties, meeting the quality standards of demanding industries such as automotive and aerospace.

Energy efficiency and cost effectiveness

- Energy Efficiency Directly Impacts Costs

- Energy Costs

- Metal Loss

- Equipment Lifespan and Maintenance

- Overall Production Costs

Modern furnace design focuses on energy efficiency. For example by using efficient equipment such as induction furnaces or electric arc furnaces. These equipment are able to heat the metal quickly and use less energy. In addition, by optimizing the melting and holding processes, it can reduce the production costs significantly and improve melting efficiency.

Energy Efficiency Directly Impacts Costs

- Energy costs can account for up to 25%–30% of the total cost of a die-cast product, with furnace energy consumption accounting for the highest proportion, with approximately 58%–67% of production costs attributable to the melting furnace.

- Inefficient furnaces (most traditional gas-fired or resistance furnaces have a thermal efficiency of only 15%–40%) result in significant heat loss, fuel waste, and metal oxidation, which in turn increases raw material and energy costs.

- By improving furnace thermal efficiency (e.g., using induction furnaces, heat recovery systems, or high-efficiency burners), energy consumption can be reduced by 10%–30%, significantly reducing production costs.

Energy Costs

In a typical aluminum die-casting plant, a 10% reduction in energy consumption for a single high-efficiency furnace can translate into hundreds of thousands of yuan in annual electricity and gas savings.

Metal Loss

Compared to gas-fired furnaces, electric furnaces can reduce oxidation losses by 0.2%–0.5%. In large-scale production, this can save thousands of kilograms of aluminum, directly translating into a significant reduction in raw material costs.

Equipment Lifespan and Maintenance

High-temperature-resistant, low-thermal-expansion lining materials and heat recovery systems can extend the furnace’s lifespan by 5–10 years, reducing replacement and overhaul costs.

Overall Production Costs

Taking all these factors into account, an optimized furnace can reduce the unit cost of die-cast parts by 5%–15%, offering significant economic advantages in highly competitive industries such as automotive and electronics.

Adapt to the needs of different metals

- Different types of metals require different melting conditions. For example, light metals such as aluminum and magnesium usually use crucible furnaces or induction furnaces.

- While low melting point metals such as zinc and copper. They are more suitable for built-in furnaces in hot cavity die casting. The choice of furnace directly affects the melting speed, fluidity and quality of the final casting.

HAICHEN furnace solutions in die casting

- Solve Temperature Instability for an Automotive Supplier

- Reduce Energy Costs for a Consumer Goods Maker

Solve Temperature Instability for an Automotive Supplier

A Chinese auto parts maker had porosity defects in aluminum wheels. The problem was temperature swings in their old furnace. HAICHEN engineers suggested a new resistance furnace with precise digital control. The new system kept the aluminum temperature within ±5°C. Porosity defects dropped by over 90%, and wheel strength increased.

Reduce Energy Costs for a Consumer Goods Maker

A manufacturer of zinc alloy fittings saw very high electricity bills. Their old furnace had poor insulation. We replaced it with a HAICHEN-recommended energy-saving furnace. The new furnace used 30% less power. It also melted metal faster, supporting a 15% increase in production speed.

Delivering Complete and Efficient Melting Systems

As a professional die casting machine manufacturer, HAICHEN understands the entire process. We know that a top machine needs a top furnace. Our advantage is offering matched systems. We select the right furnace technology for your metal and production goals. This ensures seamless operation from melting to casting, giving you high quality, low waste, and the best return on investment.

Reduce transportation losses

- In cold chamber die casting, it need the metal need transferred from an external furnace to the die, which increases heat loss and operational complexity.

- In contrast, the built-in furnace of hot chamber die casting reduces this link. Thereby improving production efficiency and reducing the risk of casting defects.

Support high-quality casting production

- The furnace not only affects the melting process of the metal, but also determines the surface quality and internal structure of the casting. For example, using high-quality crucible materials.

- Such as silicon carbide) can avoid metal contamination, thereby improving the surface finish and mechanical properties of the casting

Therefore, choosing the right furnace type and optimizing its performance are key factors. That to ensure the success of the die casting process.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.