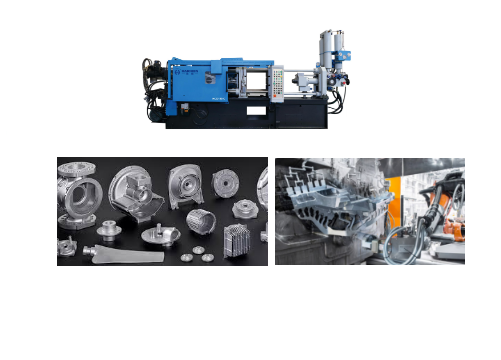

Aluminum die casting is widely used in many fields, making it one of the most popular materials for this manufacturing process.

When selecting die casting materials, consider specific application requirements such as strength, weight, cost, environment, etc.

Aluminum die casting is suitable for high-strength and lightweight needs, zinc die casting is suitable for precision and low-cost production, and magnesium die casting is suitable for lightweight and complex structural parts.

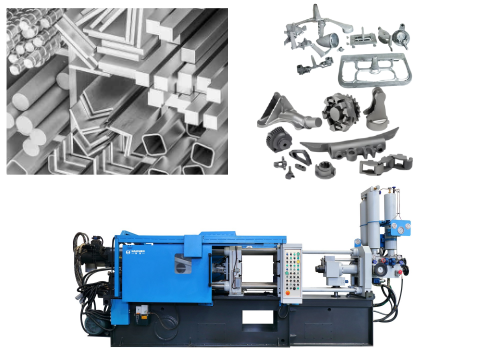

Aluminium

Aluminum is a metallic chemical element with the chemical symbol Al, atomic number 13, and atomic weight of approximately 27.

It is the third most abundant element in the earth’s crust (after oxygen and silicon) and the most abundant metallic element, but usually in the form of compounds such as silicates or oxides, the main ore being bauxite.

The reasons for aluminium used in die casting

Lightweight of aluminum die casting

- Low Density: Aluminum has a low density, making it much lighter than many other metals. This is particularly beneficial in industries like automotive and aerospace, where weight reduction is crucial for fuel efficiency and performance.

High Strength-to-Weight Ratio

- Durability: Despite its light weight, aluminum offers excellent strength, providing durability and resistance to wear and tear.

Excellent Corrosion Resistance of aluminum die casting

- Oxidation Resistance:Aluminum naturally forms a thin oxide layer on its surface, which protects it from corrosion. This makes it ideal for use in environments where moisture and other corrosive elements are present.

Good Thermal and Electrical Conductivity

- Heat Dissipation: Aluminum’s high thermal conductivity makes it suitable for components that need to dissipate heat, such as heat sinks and electronic housings.

- Electrical Applications: Its good electrical conductivity also makes it useful in electrical and electronic applications.

Ease of Machinability

- Machining: Aluminum is relatively easy to machine, allowing for precise and intricate designs. This is particularly important in die casting, where complex shapes and fine details are often required.

Recyclability

- Sustainability: Aluminum is 100% recyclable without losing its properties, making it an environmentally friendly option. Recycled aluminum requires significantly less energy to process compared to primary aluminum production.

Cost-Effectiveness

- Material Cost: While aluminum can be more expensive than some other materials, its benefits often outweigh the costs, especially when considering the total lifecycle and performance of the product.

- Production Efficiency: The die casting process with aluminum is highly efficient, allowing for high-volume production with minimal waste.

Aesthetic Appeal

- Surface Finish: Aluminum can be easily finished with various surface treatments, such as anodizing, painting, or polishing, to enhance its appearance and provide additional protection.

Dimensional Stability

- Precision: Aluminum maintains dimensional stability during the die casting process, ensuring that the final product meets tight tolerances and specifications.

Versatility

- Wide Range of Applications: Aluminum’s properties make it suitable for a wide range of applications, from automotive parts and aerospace components to consumer electronics and household items.

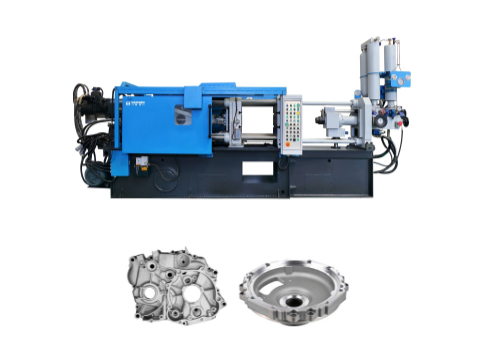

Haichen aluminium die casting machine supplier

Haichen is a well-known supplier of aluminum die casting machines, offering a range of equipment designed for high-quality and efficient die casting processes.

And we mainly supply cold chamber and hot chamber die casting machines.

Our range of products and customization options make them a reliable choice for manufacturers looking for high-quality die casting solutions.

Whether you need a fully automatic system or a semi-automatic machine, Haichen offers equipment that can meet diverse production requirements.