Zinc die casting machine market size is forecast to increase by USD 2.85 billion, at a CAGR of 4.7% between 2024 and 2029.

Think of it as a niche industry where specialized equipment molds molten zinc into precise shapes—everything from car parts to smartphone components.

The zinc die-casting machine market continues to grow globally, especially in regions such as Asia, North America and Europe.

Now, this market isn’t just surviving; it’s thriving globally. Regions like Asia, North America, and Europe are leading the charge.

For example, Asia-Pacific (APAC) alone is projected to hit a market value of $2.7 billion by 2032, driven by booming automotive and electronics sectors .

Meanwhile, North America’s market is expected to reach $1.2 billion in 2024, thanks to advancements in lightweight materials for industries like aerospace .

Here’s the kicker: China isn’t just playing the game—it’s reshaping it. As the world’s top producer, China’s market share is skyrocketing.

Why? They’re doubling down on tech upgrades (think smart automation and energy-efficient machines) and tapping into high-demand sectors like electric vehicles.

Reports predict China’s zinc die-casting industry will focus heavily on eco-friendly processes, like lead-free alloys, to meet global sustainability standards.

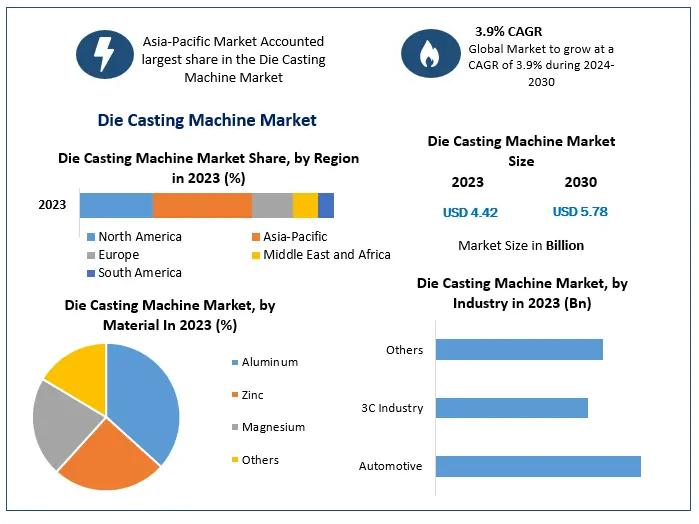

The global zinc die casting machine market size and growth rate

Global zinc alloy die-casting machine market size forecast from 2023 to 2029:

Industry analysts estimate that the global die-casting zinc alloy output value will reach USD 1 million by 2029, with a compound annual growth rate (CAGR) ranging from 3.9% to 7.13% during the 2023-2029 period.

Regional distribution of the zinc die-casting machine market

The zinc die-casting machine market shows a distinct regional distribution worldwide, mainly concentrated in

- North America

- Europe

- Asia-Pacific region

North America:

North America is one of the important regions in the zinc die-casting machine market, especially the United States and Canada.

Due to the development of the automotive industry, North America has a strong market demand for the application of zinc die-castings.

In fact, North America holds a certain share in the die-casting machine market, but its market share is relatively stable, mainly due to the maturity of technology and the relatively high consumption level.

Europe:

Europe is another major region in the zinc die-casting machine market. Countries such as Germany, France, and Italy have shown strong market demand for magnesium alloy die-castings.

The die-casting machine market in Europe is mainly dominated by German enterprises.

With a relatively high market share and strong competitiveness in the high-end die-casting machine field.

Asia-pacific region:

The Asia-Pacific region is the fastest-growing area for the zinc die-casting machine market, especially in China and Japan.

As the world’s largest producer and consumer of automobiles, China has a strong demand for magnesium alloy die-castings driven by the lightweighting of automobiles.

In Japan, the demand for magnesium alloy die-castings in the aerospace and electronic products sectors is constantly increasing, becoming an important growth point in the magnesium alloy die-casting market in the Asian region.

In addition, China also has strong competitiveness in the manufacturing of die-casting machines.

There are more than 3,000 die-casting enterprises in China.

The global die-casting machine manufacturing industry is mainly distributed in China, Japan, Switzerland, Italy, Germany and the United States.

Among them, the output of Japan, Germany, Italy and Switzerland accounts for about 20% of the global total, and their output value is about 50%.

They also dominate the markets of developed countries such as Europe and North America.

Other regions:

Latin America, the Middle East and Africa, such as South Africa, have relatively small shares in the zinc die-casting machine market.

However, with the development of globalization, the market demand in these regions is also gradually increasing.

For instance, due to the rapid development of manufacturing in India and Southeast Asian countries, the demand for die-casting machines has been increasing year by year.

Zinc Market Demand & Applications

Zinc alloys have good corrosion resistance and thermal conductivity, making them excellent in applications that require temperature control.

Such as kitchen cabinets, appliances, and industrial equipment.

In addition, zinc die castings are also used in many industries such as auto parts, furniture hardware, and electronic equipment housings.

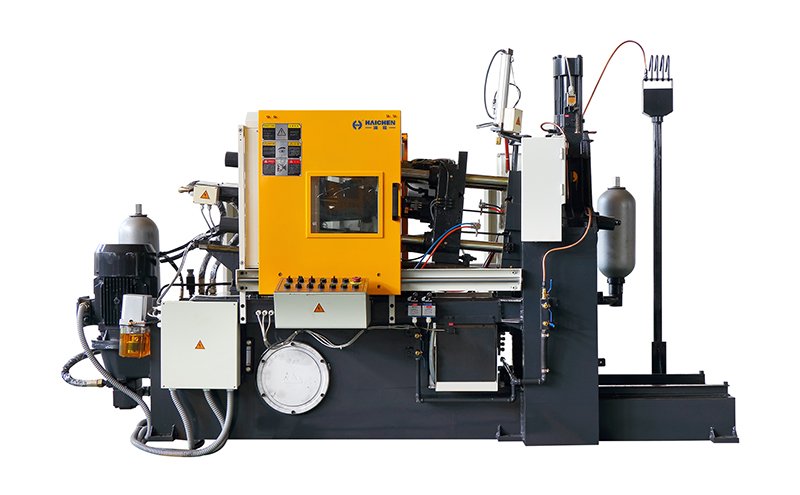

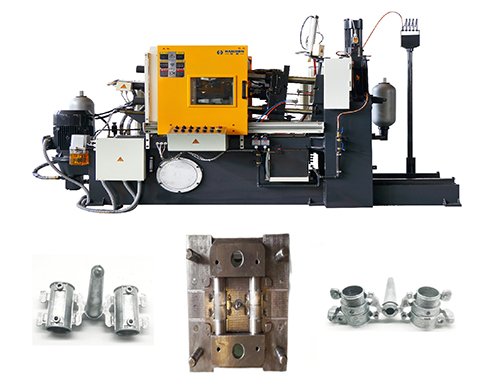

Haichen has provided customers with different models of hot chamber die-casting machines and molds for the production of door handles, medals, connectors, and other items.

Haichen’s zinc die-casting

Zinc die casting is a metal forming process that involves injecting molten zinc alloy into a steel mold cavity.

Where it is rapidly cooled and cured under high pressure to produce metal parts with complex shapes and precise dimensions.

Haichen’s zinc die casting process is widely used in several industries due to its efficiency, cost-effectiveness, and suitability for high-volume production.

The zinc die casting process involves several steps, starting with the zinc alloy being melted at high temperatures and then injected into a pre-prepared steel mold through a die casting machine.

The mold cavity is precision machined to ensure high accuracy and tight tolerances.

After injection, the molten metal cools and solidifies rapidly under high pressure, forming the final part.

Haichen’s entire die casting process is highly automated and has a short production cycle, making it suitable for large-scale production.

Zinc die casting machine development trends

- Overall market growth trend

- Regional market distribution

- End application

- Technological innovation and application field expansion

Overall market growth trend

The zinc alloy die casting industry has shown a steady growth trend in recent years.

Especially in the fields of automobiles, home appliances and construction.

With the advancement of manufacturing technology, zinc alloy die castings have made significant breakthroughs in improving mechanical properties, surface quality, production efficiency and reducing costs.

In 2022, China’s zinc alloy die casting output reached 408,000 tons, accounting for 8.0% of the total die casting output.

Regional market distribution

North China and East China are the main consumption areas of die-cast zinc alloy, accounting for 63% and 59% respectively.

Other regions such as South China and Central China also have some market demand, but relatively little.

End application

Zinc alloy die castings are widely used in home appliances, automobiles and construction.

Among them, the market demand in the home appliance and automobile fields is relatively stable.

While the market demand in the construction field is greatly affected by the real estate market.

The peak of the real estate market has passed, but the subsequent performance of sectors.

Such as exports, automobiles and home appliances is expected to have a positive impact on market demand.

Technological innovation and application field expansion

Zinc alloy die-casting machine will pay more attention to technological innovation and application field expansion.

Improve the overall performance through new materials and new technologies, and use environmentally friendly materials to reduce energy consumption in the production process and reduce the impact on the environment.

With the continuous innovation of technology and the continuous improvement of technology.

The application field of zinc alloy die casting will be further expanded, and the market demand will continue to grow.