The zinc door handle production process uses zinc alloy as material. It gets the rough part by die casting, then goes through post-processing to make the final product.

Zinc alloy door handles are a common door handle material with many advantages and application requirements. Because they have good corrosion resistance and wear resistance and are suitable for a variety of environments. Zinc alloys are easy to process and form, and can use to manufacture complex shapes and thin-walled precision hardware.

Zind door handle can treat with a variety of surface treatments such as electroplating, painting, and polishing to present a variety of colors and styles. So zinc alloy door handles are relatively low in cost and suitable for large-scale production

The die casting manufacturing of zinc alloy door handle production process usually includes the following main 6steps:

- material preparation

- mold design and preheating

- Injection

- Cooling and solidification

- Take out

- Post-processing

Material preparation

- Low melting point

- Superior mechanical performance

- Molding advantages

- Environmental Characteristics

Generally, the melting point of zinc alloy is between 419-420°C. During the heating process, other elements may need to be added to improve the properties of the alloy, such as magnesium or silicon, etc. So zinc alloy (mainly Zamak series) material has become the core material of door handles due to the following characteristics:

Low melting point

(385-420 ℃) improves die-casting efficiency, and the mold life can reach more than 500000 times.

Superior mechanical performance

Hardness 65-140HB, tensile strength 260-440MPa, superior to aluminum alloy.

Molding advantages

capable of casting 0.4mm thin-walled structures with a tolerance accuracy of ± 0.05mm, achieving complex geometric shapes.

Environmental Characteristics

Compliant with Zinc Mark certification requirements, with a zinc content of over 80% to ensure material traceability.

Mold design and preheating

- Mold material selection

- Mold structure design

- Pin design

The mold is made of steel and needs to be specially designed according to the product design. Before die casting, the mold need preheat to a certain temperature. That’s to ensure rapid solidification and reduce defects when the metal is injected.

Mold material selection

Tool steel or special alloy steel is usually used to ensure the wear resistance and heat resistance of the mold.

Mold structure design

This including pouring system, cooling system, and ejector structure. The design of the pouring system should ensure that the molten metal can evenly fill the mold, avoiding defects such as porosity and shrinkage. The cooling system is used to control the temperature of the mold, ensuring rapid solidification of the molten metal in the mold and reducing thermal stress.

Pin design

Pin is used to eject molded parts, and its shape and size should be optimized according to the specific structure of the door handle to ensure the quality of the workpiece during the ejection process.

Preheating process

- Preheating temperature

- Preheating method

Preheating is an essential step in the zinc alloy die-casting process. It aims to increase the mold temperature, reduce the temperature difference between the molten metal and the mold. Thereby reducing thermal stress and improving the quality of castings.

Preheating temperature

According to literature, the preheating temperature for zinc alloy molds is usually between 200-350 °

Preheating method

- Natural gas flame heating: Heating molds through natural gas flames, suitable for small and medium-sized molds.

- Electric heating rod heating: By using an electric heating rod to locally heat the mold, it is suitable for situations that require precise temperature control.

- Mold temperature machine heating: Use a mold temperature machine to heat the mold as a whole, suitable for large or complex structure molds.

Injection

The molten zinc alloy is injected into the mold cavity at high pressure and speed. This process usually complete within a few seconds, for example, the cycle time of the hot chamber die casting process can be as short as a few seconds. During the injection process, the molten metal enters the mold cavity at high speed (10-100 m/s) and high pressure (2-250 MPa).

Cooling and solidification

- The Effect of Cooling Rate on Solidification Structure

- Process control of cooling and solidification

In the mold cavity, the zinc alloy cools rapidly and solidifies. To ensure the integrity and quality of the casting, the mold needs to apply a certain clamping force to prevent deformation during the injection process.

The Effect of Cooling Rate on Solidification Structure

The cooling rate has a significant impact on the solidification structure of zinc alloys. We can see as the cooling rate increases, the solidification structure of the alloy will refine, so improving its mechanical properties. For example, in the hot chamber die casting process, controlling the cooling rate is crucial for preventing zinc layer cracking and improving its corrosion resistance. In addition, an increase in cooling rate can lead to the refinement of zinc grains, thereby reducing internal stress and crack formation.

Process control of cooling and solidification

In the manufacturing process of zinc alloy door handles, precise control of cooling and solidification is required. For example, in the die-casting process, the temperature control of the mold and the design of the cooling system are crucial to ensure uniform cooling of the metal and avoid defects such as shrinkage, cold shut, etc. In addition, temperature control of the mold can also reduce thermal stress, thereby improving the dimensional stability and surface quality of the castings.

Take out

When the casting is completely solidified, the mold opens and the ejection mechanism ejects the product from the mold. This step requires good control of the thickness of the die casting to avoid quality problems caused by uneven thickness.

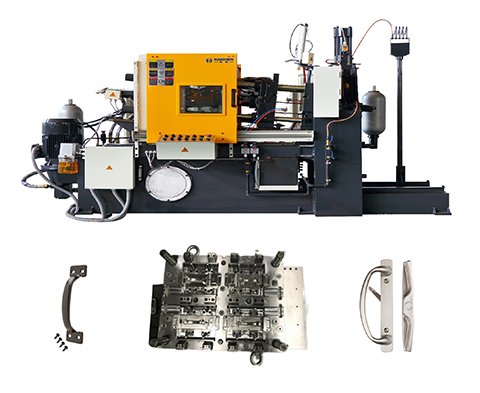

HAICHEN Practice Of Zinc Door Handle Production Process

HAICHEN die casting machines offer high stability and precise control. They help solve many challenges in the zinc door handle production process.

Customer Need

One of Haichen door handle maker customers wants to raise the yield rate for chrome plating on a high-end product line. They also wanted to lower the failure rate in strength tests due to internal pores.

HAICHEN’s Process Analysis and Machine Solution

HAICHEN engineers found the root cause: unstable injection speed and slow intensifier response on the old machine. They suggested a new HAICHEN servo die casting machine. It has a precise injection control system and real-time feedback.

Process Optimization and Parameter Setting

For the zinc door handle production process, they set a slower slow-shot speed for smooth air venting. They set a faster start point for fast-shot and higher final intensification pressure for dense filling.

Results Achieved

After the change, the casting surface got much better. This gave an excellent base for plating. The chrome plating yield rate went up by 18%. Also, the internal quality became stable. The strength test pass rate went above 99.5%. Overall production efficiency improved.

Post-processing

- Electroplate

- Spray painting and powder coating

- Polishing and Grinding

- Assembly and packaging

The zinc alloy door handle after die casting may need further surface treatment or machining to meet the accuracy and appearance requirements of the final product.

Electroplate

Electroplating is a crucial step in the post-treatment of zinc alloy door handles.

It is mentioned that the electroplating process of zinc alloy door handles is usually completed by external suppliers to increase the surface glossiness. For example, it is mentioned that zinc alloy door handles can be treated with nickel plating or PVD gold plating to enhance their appearance and durability. In addition, it was mentioned that the surface treatment of zinc alloy door handles includes bright chromium, matte chromium, nickel plating, polishing, painting, powder coating, etc.

Spray painting and powder coating

Spray painting and powder coating are common surface treatment methods used to give zinc alloy door handles rich colors and good weather resistance.

Detailed description of the post-treatment process for zinc alloy door handles, including spray coating and drying and curing steps. During the spraying process, 90% of the excess powder can be recycled and reused, while the remaining 10% of the powder is mainly deposited and recovered, with only a small amount escaping. During the drying and curing process, the coating is cured at a temperature of 180-200 ° C for about 30 minutes to ensure its adhesion and durability.

Polishing and Grinding

Polishing and grinding are key steps in improving the surface smoothness and aesthetics of zinc alloy door handles.

It is mentioned that the polishing process of zinc alloy door handles is usually treated with acid or alkaline solutions to enhance the surface glossiness. In addition, it was mentioned that the post-treatment of zinc alloy door handles includes steps such as polishing, sanding, CNC turning, milling, drilling, and grinding.

Assembly and packaging

The post-treatment of zinc alloy door handles also includes assembly and packaging steps.

It is mentioned that the post-processing process of zinc alloy door handles includes steps such as painting, drying, assembly, and packaging. During the assembly process, the door handle is combined with components such as hinges and lock bodies to ensure its functionality and stability. In terms of packaging, white cardboard boxes and wooden boxes are usually used, and OEM customized colors are supported.

During the entire die casting process, vacuum die casting technology can significantly improve the density of castings and reduce defects such as pores. For example, by introducing a vacuum in the mold cavity, the gas content in the casting can be reduced, thereby improving its mechanical properties.

Haichen zinc door handle die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine.They have durable and highly precise features. Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

Haichen have rich experience of manufacturing zinc door handles. As per each customer’s specific demand, we can supply zinc door handle production line including hot chamber die casting machine. Also with auto ladle, auto sprayer and other necessary auxiliary equipment to improve the production efficiency and products quality.