What is industrial robot used in die casting machine

The uses of industrial robots in die casting machines include automating tasks like part removal, trimming, and inspection. Under the splash of 800℃ molten aluminum and the impact of 15Bar mold closing, the die-casting workshop is one of the most demanding environments in the industrial field. Industrial robots have become rigid demands with three capabilities: […]

Programmable logic controller (PLC)of die casting machine

Die casting machine PLC is a digital operation electronic system, it controls the automatic operation process. In die-casting machines, Programmable Logic Controller (PLC) is a key equipment widely uses in industrial automation control. PLC achieves precise control over various operational aspects of the die-casting machine through its powerful logic operations, sequential control, timing, counting, and […]

Brands of controller of die casting machines

The brands of controller of the die casting machine includes: The Die casting machine controller is an electronic device used to control and manage the entire production process of the die casting machine. It ensures the stable operation of the die-casting machine under the set parameters by receiving signals from sensors and executing corresponding control […]

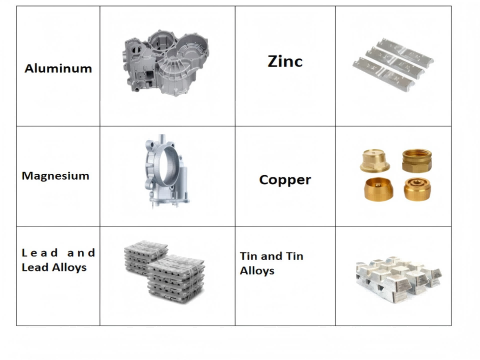

The 6 Best Materials for die casting

Die casting 6 best materials mainly include aluminum, zinc, magnesium, copper, lead and lead alloys, tin and tin alloys. Die casting is a manufacturing process in which molten metal is forced into a mold cavity under high pressure. The choice of material significantly impacts the product’s properties, durability, and application. Die casting 6 best materials […]

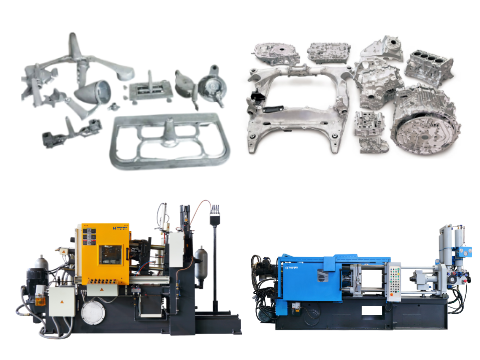

What Is the High Pressure Die Casting (HPDC)Process?

High Pressure Die Casting Process: High-Pressure die casting is a casting process in which molten metal is injected into the mould cavity under high pressure and high speed, and the casting is formed by cooling and pressure curing. The process is widely used to produce metal parts with complex shapes, high precision and high […]

Advantages of die casting Furnace

Advantages of die casting Furnace significantly: These advantages of furnaces make die-casting machine furnaces widely used in the field of metal parts manufacturing. Especially in automotive, home appliances, aviation, and many other industries. Die casting machine melting furnace is used to heat the metal material to the melting point above, for casting equipment. In die-casting production, the main […]

What are the fundamentals of die casting?

The fundamentals of die casting mainly includes the following steps: Die Casting is a metal forming process that uses the basic fundamentals of injecting molten metal under high pressure into a cavity called a mold, allowing it to cool and solidify into the desired shape. Die casting is an efficient metal casting processing method that […]

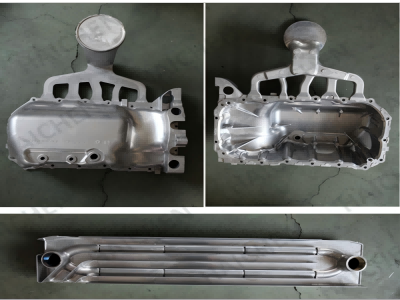

What is the temperature of die casting mold

Die casting mold temperature is generally between 150-300 degrees, it is suitable casting stability temperature range. Mold temperature generally is the surface temperature of the mold, and its standard measurement should be about 1/3 of the pouring temperature of the alloy liquid. But the temperature of die casting molds varies depending on the type of alloy […]

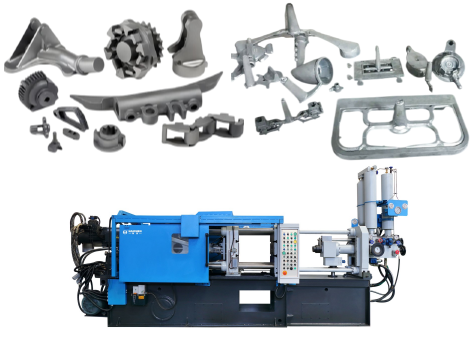

Application for High Pressure Die Casting

High pressure die casting application mainly applies for the automotive industry, aerospace industry, electronics industry, consumer goods and medical devices. High Pressure Die Casting (HPDC) is a highly efficient metal casting process that is widely used in a number of industries to produce complex and highly accurate metal parts. The process works by injecting molten metal under […]

Steps Involved in the Die Casting Operation

The die casting operation steps involve preparing the mold, heating metal, injecting it into the mold, cooling, ejecting the part, post-processing, etc. Die casting stands out as a go-to method for creating detailed components across many industries, thanks to its compatibility with versatile materials like aluminum, zinc, and copper alloys. Understanding the importance of each […]