What is a vacuum machine used for die casting?

The purpose of vacuum machine for die casting is to remove air and gas from the mold cavity before injecting molten metal. Vacuum machines are particularly indispensable in improving both the quality and consistency of the final product in the die casting process. Especially in the case of die casting for a workpiece, they are […]

Human Machine Interface (HMI)of die casting machine

Die casting machine HMI is a critical component that facilitates interaction between the operator and the machine. It provides a user-friendly platform to monitor and control the machine’s operations. It typically includes both hardware and software components. The hardware component may include input devices such as touchscreens, buttons, switches, etc., while the software component is responsible for […]

How does a chiller work for die casting machine

The working principle of chiller is to circulate the coolant through the mold to absorb heat, then cool it in the evaporator of the chiller and then circulate it. Like other manufacturing processes, die casting requires strict temperature regulation during the entire process of production to maintain quality. This is because the thermal dynamics of […]

What is the best die casting temperature?

The best die casting temperature depends on a number of factors.During the die casting process, temperature will affect the mechanical properties to a certain extent. Temperature control is crucial, and too low a temperature will affect metal flow and casting quality. Too high a temperature may also damage the mold and cause other defects. In […]

What products are made by high pressure die casting?

High pressure die castingcan produce complex shapes with intricate details and thin walls, and the castings usually have a smooth surface after they come out of the mold. It can handle tighter tolerances and produces much less scrap than other similar methods. It is compatible with a wide range of non-ferrous metals and is cost-effective […]

Application for die casting machine control system

Die casting machine control system in the modern die casting process plays a vital role.With the integrated control system, you gain a comprehensive overview of your production unit. This enables you to refine your die-casting processes and monitor production conditions. Our bespoke solutions for aluminium and magnesium die-casting processes are designed to enhance the productivity […]

What are the raw materials for die casting?

The raw materials for die casting are mainly various non-ferrous metals and their alloys,like Zinc,Aluminium and Copper. Which have a low melting point and are suitable for injection into moulds under high pressure for forming. Details of various metal die-casting raw materials Commonly used die-casting materials are: Zinc alloy zinc alloy is one of the […]

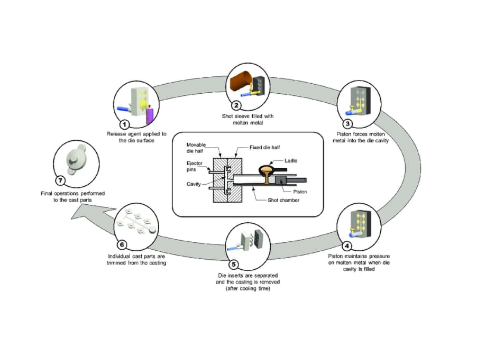

What are the steps of die casting?

Die casting steps are manufacturing process in which molten metal injecting into a metal mould cavity under high pressure. It is a precision casting process in which molten metal is injected into a mould under high pressure,. This allowing it to cool rapidly and form the desired shape. Die casting is good in automotive, electronics, […]

Which material is most suitable for die casting?

Aluminum is the most suitable material for die casting. It has the advantages of light weight, high strength, good corrosion resistance, and high thermal conductivity, making it one of the most commonly used materials in die casting. In addition, aluminum has excellent mechanical properties and provides good dimensional stability and surface finish during the die […]

Working concept of conveyors for die casting machine

The working concept of conveyors in die casting machines involves moving parts efficiently through the production stages, from casting to cooling. The implementation of conveyor systems significantly improves the productivity and automation of the die casting process. The modern die casting industry cannot operate without these systems because of their impact on production efficiency, decrease […]