Zinc pipe fitting production line

Zinc pipe fitting production line mainly includes raw material, mould and hot chamber die casting machine. The use of hot chamber die casting machine in the production of zinc pipe fittings is a common manufacturing process. This process is suitable for low melting point metals such as zinc, tin, and lead. The working principle of […]

Types of industrial robots for die casting machine

Types of industrial robots: In the foundry industry, industrial robots can be used for a variety of different tasks, including casting, painting, cleaning, cutting, and polishing. Industrial robot——Intelligent foundry robot The intelligent foundry robot uses advanced artificial intelligence technology to monitor key parameters. Such as temperature and pressure in the casting process in real time […]

Advatnages of scrap conveyor for die casting machine

For die casting machines, scrap conveyor belts offer the following advantages: Scrap conveyor belts for die casting machines provide important support for die casting production by increasing efficiency. Reducing energy consumption, enhancing reliability, and adapting to a wide range of working environments. Conveyor belts can turn a laborious task into a breeze; they help […]

What are chillers used for in casting?

Chillers in die-casting mainly have these functions: The chiller is the core of the die-casting temperature control system, ensuring the stability of the mold and the consistency of the product. When selecting the type, it is necessary to take into account the material properties, mold structure and production capacity requirements. And establish a preventive maintenance […]

How to make zinc pipe fitting?

The complete production of zinc pipe fitting requires the assistance of many different processes.The first step is to make the zinc alloy material into a blank through the die-casting process. Next, the blank is treated with cooling and flushing, followed by the batching and tapping process. After completion, it is polished and electroplated. Finally, the […]

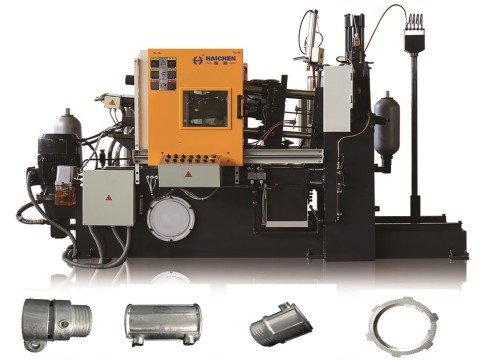

What machines are used to produce zinc pipe fitting

To produce zinc pipe fittings, specialized machines known as zinc pipe fitting making machine are used. These machines cope with the exceptional characteristics of zinc for its exact and uniform machining throughout the process. Zinc pipe fitting manufacturing machinery consists of several functional units: melting furnaces, die casting sets, and post-processing equipment which provide strong […]

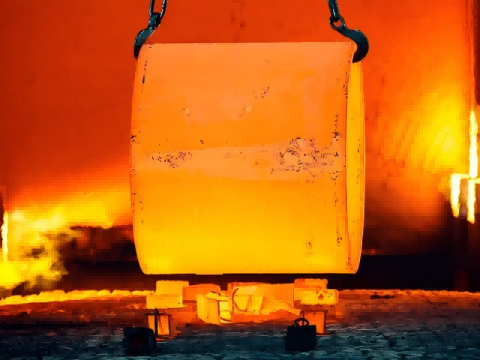

The Features of Heat Treatment In Die Casting

Critical heat treatment features in die casting are utilized to enhance mechanical properties, dimensional stability, and corrosion resistance through controlled heating and cooling cycles. In the die-casting production process, heat treatment is a crucial means to improve mold performance and extend its service life. By precisely controlling the heating and cooling processes, heat treatment can […]

What are the two heat treatment processes?

Two heat treatment processes are quenching and tempering.These two common heat treatment processes are helpful to improve the mechanical properties of metal die casting products. Different materials serve distinct purposes in engineering applications, necessitating performance treatments to meet essential requirements. Engineers employ various techniques during the manufacturing process to achieve the desired properties. Quenching and […]