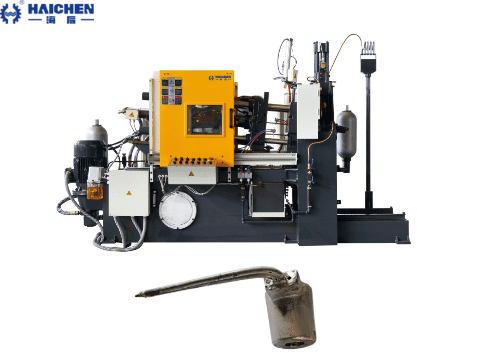

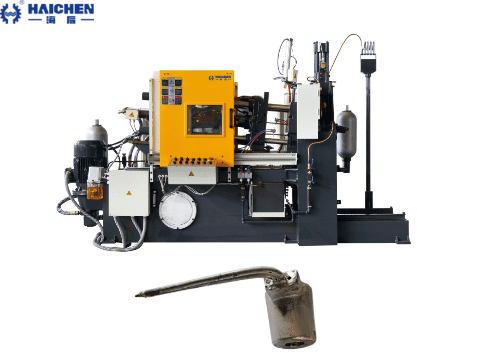

What is die casting machine heating bush?

A die casting machine heating bush is a component of a die casting machine used to heat the mould or mould cavity.During the die casting process, the mould needs to be kept at a certain temperature to prevent thermal shock and casting defects caused by temperature differences. The heater bush usually maintains the temperature of […]

Raw materials for die casting heating bush

Raw materials for a die casting heating bush also commonly known as Stellite alloys. For die casting bushes, especially heating bushes in continuous casting, you need high-performance materials like Stellite alloys Stellite 6, 20. Or specialized ceramic materials like Aluminum Titanate for wear, heat, and corrosion resistance, preventing metal buildup and ensuring long life, as opposed to standard casting metals […]

Advantages of die casting machine heating bush

The heating bush in a die – casting machine offers several advantages, including precise temperature control for consistent metal flow, enhanced part quality through uniform cooling, and increased production efficiency by reducing cycle times and minimizing downtime. The heating bush is a critical component in die – casting machines, playing a significant role in ensuring […]

Types of Heating bush for die casting machine

Die casting heating bush types includes high-frequency induction heating bush, electric Heating bush, hot runner heating bush and so on. In a die casting machine, a heating bush is a device uses to increase the temperature of the mold. It ensures that the molten metal reaches the appropriate temperature when it is injected into the mold. Depending on […]

Functions and Applications of die casting machine heating bush

Function Purpose of Heating bush: The Heating Bush in die-casting machines ensures that molten metal maintains the ideal temperature just before injection, thus enabling seamless flow into the die. Operating quietly behind the scenes, it thus supports the production of the high-precision components critical in modern manufacturing. By keeping the metal at a consistent heat, […]