Choosing the best maintenance for die casting machine

The best maintenance for a die casting machine involves: The die-casting machine has strict requirements for the safe operation of the operator; the correct maintenance of the machine can not only protect the safety of personnel and equipment, but also help improve economic benefits. In order to ensure the normal operation of the die-casting machine, […]

Electrical System of die casting machine maintenance

The electrical system maintenance of a die casting machine is a crucial component that controls and monitors various aspects of the machine’s operation. Given the high failure rate of molds and equipment in the die casting industry, companies must prioritize preventive maintenance to avoid production disruptions caused by equipment failures. Consequently, by developing a comprehensive preventive […]

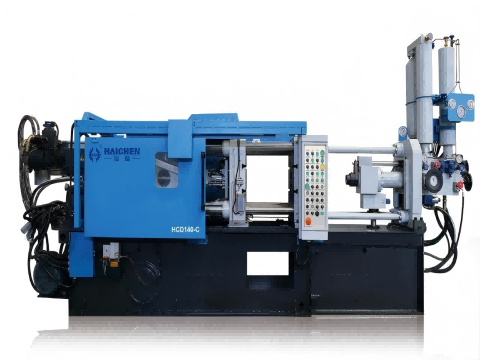

Importance of Die Casting Machine Maintenance

Die Casting Machine Maintenance is vital to ensure its efficient and reliable operation.It is a necessary management tool to ensure the safe operation. Maintenance of die casting machines is the key to ensuring their efficient, safe and sustainable operation.By regularly checking, cleaning, lubricating and replacing parts, the life of the equipment can be extended, production […]

Lubrication part of die casting machine maintenance

Die casting lubrication part maintenance includes choose the right lubricant, frequency and method of using lubricants and so on. The core of die-casting machine lubrication maintenance is to regularly clean and ensure the lubrication channels are unobstructed + add appropriate lubricants according to the standard cycle + monitor the status of the hydraulic/lubrication system.At the same time, […]

Injection Unit of die casting machine maintenance

Injection Unit of die casting maintenance is crucial for consistent production quality and minimizing downtime. The injection unit of the die casting machine is responsible for accurately metering and injecting molten metal into the mold cavity under high pressure and at high speed. Any degradation in its performance—such as plunger wear, pressure loss, or misalignment—can […]

Why Choose Cold Chamber Die Casting?

Why choose cold chamber die casting: Choose cold chamber die casting is because it is a kind of high-efficiency equipment used for the manufacture of metal parts. Especially suitable for the forming of metals with high melting points such as aluminum alloys, magnesium alloys, etc. What Is Cold Chamber Die Casting? Cold chamber die casting […]