Pressure casting vs other Processes

Pressure casting is quickly cooled and formed by injecting molten metal into a precision metal mold cavity at high pressure (5-150MPa) and high speed (5-100m/s). Pressure Casting is mainly divided into High Pressure Die Casting (HPDC) and Low Pressure Die Casting (LPDC). In the design of low-pressure die-casting molds, the use of sand cores requires […]

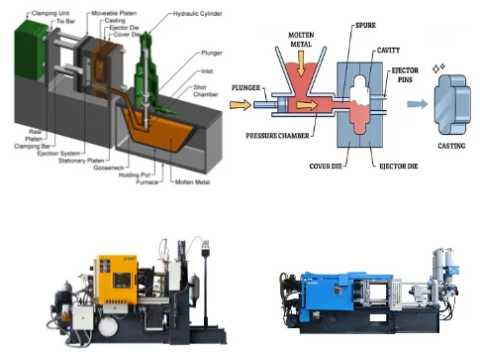

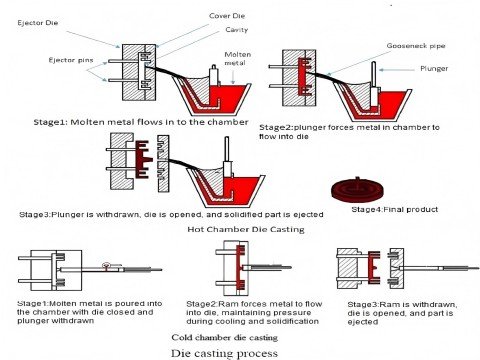

Different types of die casting process

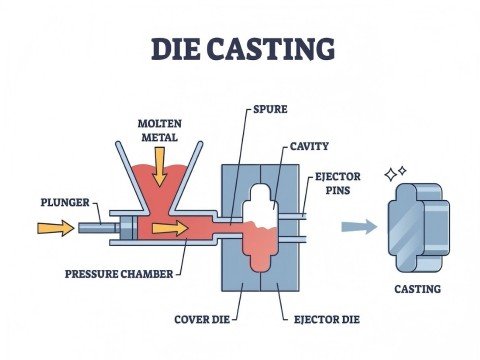

Different types of die casting process mainly have hot chamber die casting, cold chamber die casting, vacuum die casting and others. Die casting is an efficient and precise metal casting method, which is widely used to produce high-quality parts. It by forcing molten metal under high pressure into a mold cavity, typically manufactured from hardened tool […]

Guide to the Die Casting Process

Die casting is a manufacturing process known for producing high-precision,and efficient can produce high-precision metal parts. Conventional process of die casting Definition of Die Casting Die casting forces molten metal under high pressure into a reusable steel mold (a “die”). The process rapidly solidifies the metal into high-precision, complex-shaped parts. Manufacturers favor this method for […]

Advantages of die casting process

Advantages of die casting process: The die casting process offers numerous benefits for producing high-quality metal parts with precision and efficiency. The die casting process offers numerous advantages that make it a popular choice in modern manufacturing. High Production Efficiency Die casting allows for the rapid production of large quantities of identical parts. Its automated […]

The 4 Steps of High Pressure Die Casting

The 4 steps of high pressure die casting include mold preparation, metal injection, cooling and solidification, and part ejection. High – pressure die casting (HPDC) is a widely used manufacturing process in the metal – casting industry, known for its ability to produce complex parts with high precision and efficiency. This process is favored by […]