Comon Die Casting Cooling Defects in Die Casting

Common Cooling in Die casting defects are cold shut, thermal cracks, pores, shrinkage, thermal tearing, ejector marks.The avoidance of defects is the pathway to cost-effective high-quality aluminium die-casting production. Let alloy selection, die casting mold design, process control and simulation be critically analyzed to pre-inform and pre-resolve all possible defect issues. It will now look […]

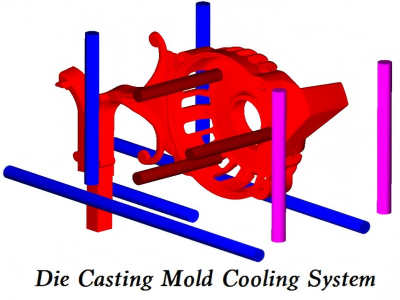

Why Cooling is so Important in Die Casting

In the die casting process, the importance of cooling cannot be ignored. Because the design and efficiency of the cooling system directly affects the quality of die castings, production speed and mold life. The importance of cooling in die casting Cooling is a critical component of the die casting process. It ensures proper solidification, reduces […]

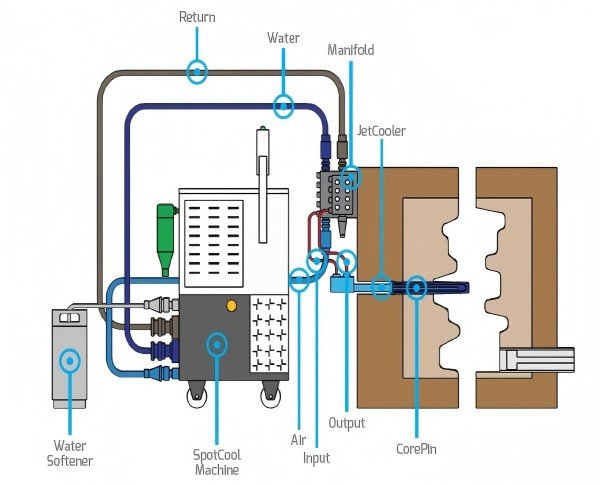

How to Optimize Cooling in Die Casting for Faster Cycle Times?

Optimize cooling in die casting is a central part of reducing cycle times and increasing efficiency. Optimize cooling in die casting to reduce cycle times requires a multifaceted approach that combines mold design, material science, process control, and advanced technology. Selection and combination strategy of Optimize cooling in die casting Water Application scenario: It is […]

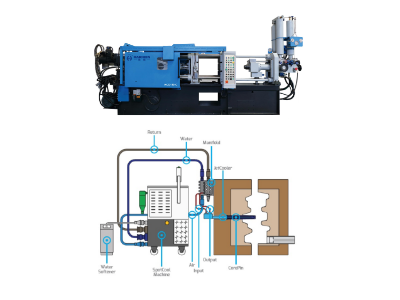

Cooling Methods in Die Casting

Cooling methods in die casting are crucial for quality and efficiency, using water or air to control mold temperatures. Die casting is a precision manufacturing process that involves injecting molten metal into a mold cavity under high pressure. One of the critical aspects of this process is the cooling phase, where the molten metal solidifies […]