Gooseneck Cost Optimization in die casting

Gooseneck cost optimization is a comprehensive process that involves balancing design, materials, processes, and innovative technologies. Specifically, the gooseneck, a curved conduit, actively transports molten metal from the furnace to the mold cavity . Furthermore, its core functions include controlling metal flow to ensure smooth and rapid filling , resisting high temperatures up to 600-650°C […]

Gooseneck structure design in die casting

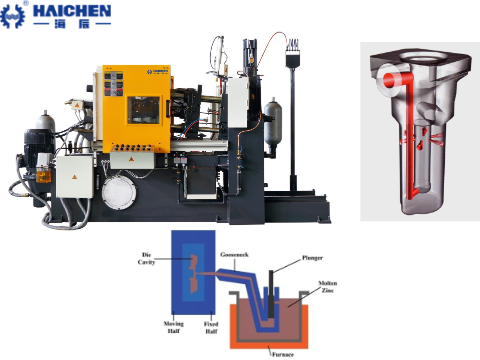

In the die casting process, the design of the gooseneck structure is a key component of Hot-Chamber Die Casting. The gooseneck is a kind of metal channel connecting the molten metal pool and mold chamber. Its design directly affects the efficiency of metal flow, casting quality and equipment life. Gooseneck structure design in die casting […]

Gooseneck in Hot Chamber die casting

In hot chamber die casting, the gooseneck is a critical component responsible for transferring molten metal and injecting it into the mold. Below are its key functions, structural features, and process-related details. Hot chamber die casting is particularly suitable for producing lead and zinc alloys. In actual operation, molten metal is automatically fed into the die casting […]

Gooseneck Installation and commissioning in die casting

Gooseneck installation and commissioning in die casting involves precise alignment with the injection system, ensuring proper sealing and connection to the mold, and conducting thorough testing to verify functionality and optimize performance for consistent metal flow and part quality. The gooseneck is a critical component in the die – casting process, responsible for transferring molten […]

How to choose gooseneck in die casting?

Choose gooseneck in die casting includes material selection, shape and function, operation mode and so on. The gooseneck is the core component of hot chamber die casting. Its main function is to connect the molten metal pool and the mold cavity. And inject the molten metal into the mold through the piston rod. Choosing a […]

Smart boosting handwheel in die casting Systems

Smart Boosting Handwheel is a high-precision operating device that integrates sensors, wireless communication, and real-time control algorithms. And is mainly used for the precise adjustment of key parameters (e.g., injection speed, pressure, and clamping force) in die casting systems. Smart boosting handwheel function Dynamic feedback control Real-time data collection through pressure and position sensors, combined […]