Common crucible materials include graphite, silicon carbide, alumina, ceramics, etc.

There are many kinds of materials for crucibles, and different crucible materials can be selected according to different use environments and conditions.

These materials have high temperature and corrosion resistance, making them suitable for high temperatures and corrosive environments.

What is crucible?

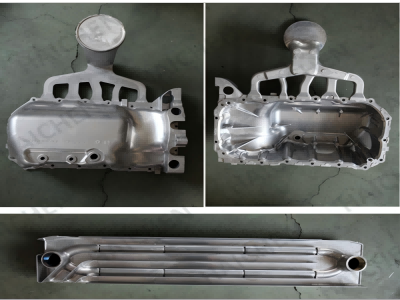

The crucible in a die casting machine is an important component used to melt and store molten metal.

In a hot chamber die casting machine, the crucible is usually fixed at the tail of the machine and is insulated by a high-temperature insulated bushing to maintain the temperature of the molten metal.

The molten metal inside the crucible needs to be heated constantly to prevent excessive temperature fluctuations, and thermocouples are usually used for temperature monitoring and the set temperature is maintained by adjusting the gas supply through automatic control devices.

What are the advantages of silicon carbide material crucibles?

- High bulk density, high temperature resistance, fast heat transfer

- Acid and alkali erosion resistance and high temperature strength

- High oxidation resistance

- Long service life

- Good thermal conductivity

High bulk density, high temperature resistance, fast heat transfer

Silicon carbide crucible materials have higher bulk density, high temperature resistance, and faster heat transfer than graphite crucibles.

Acid and alkali erosion resistance and high temperature strength

Silicon carbide crucible has good acid and alkali erosion resistance and high temperature strength.

High oxidation resistance

Silicon carbide crucibles have high oxidation resistance.

Long service life

The service life of silicon carbide crucibles is 3-5 times that of clay graphite crucibles.

Good thermal conductivity

Silicon carbide crucibles have good thermal conductivity, so they can save a lot of energy and save costs.

What are the advantages of graphite for crucible materials ?

- High temperature resistance and strong thermal conductivity

- Chemically inert and corrosion-resistant

- Resistance to acid and alkali erosion

High temperature resistance and strong thermal conductivity

Graphite crucible has excellent heat resistance and good electrical and thermal conductivity, making it have excellent control performance when used in high-temperature furnaces.

Chemically inert and corrosion-resistant

Graphite crucibles are highly corrosion-resistant, especially when working with metals and alloys at high temperatures, and their chemical inertness means that they do not react with molten substances, preventing contamination and ensuring the purity of the final product.

Resistance to acid and alkali erosion

Graphite crucible has strong corrosion resistance to acidic and alkaline solutions.

How does Haichen maintain the crucible on a daily basis?

Different crucible materials need different daily maintenance. The crucibles for Haichen die casting machine, maintain as belows:

- Regular inspection and cleaning

- Heating procedure

- Preheating and coating

- Regular maintenance

- Temperature control

Regular inspection and cleaning

Haichen’s operators often check the use of the crucible to prevent cracks and leakage due to corrosion and oxidation.

In addition, impurities precipitated at the bottom of the crucible and floating on the surface should be removed to ensure the quality of the solution.

Heating procedure

After installation, the crucible should be slowly heated to 200 °C (390 °F) for 2 hours to eliminate any moisture that may be present.

Then, it should be heated to 600 °C (1100 °F) at low power and then heated to 950 °C (1750 °F) or the desired operating temperature.

For holding applications, the temperature should be maintained at 950°C (1750°F) for approximately 1 hour to ensure that the glaze is adequately melted with the anti-oxidation coating, thus extending the life of the crucible.

Preheating and coating

Before using the crucible, Haichen will pay special attention to cleaning the dust inside the pot and preheating it to form a tight coating to improve the efficiency of use.

Regular maintenance

Haichen will regularly remove aluminum chips and oxide scale from the furnace to prevent the heating element from being short-circuited.

Check the crucible bracket for cracks every day, and adjust the height of the high-frequency heating coil to keep the distance between the crucible and the coil 2-3mm.

Temperature control

Check the potentiometer regularly to ensure that the temperature in the furnace is properly controlled. Temperature control is essential to extend the life of the crucible.