Servo sprayer advantage include improved the die lubrication effect in the die casting process, so as to reduce the casting sticky mold phenomenon.

A Servo sprayer system (servo sprayer) is a device used for die lubrication and spraying in die-casting machines. Its main function is to realize precise spraying operation through a servo motor drive.

The core of their operation lies in servo-driven control, ensuring highly consistent spray path, flow rate, and time for each application, thereby directly improving the demolding effect and surface quality of the castings.

This not only reduces mold sticking problems caused by uneven lubrication but also provides a reliable guarantee for stable and efficient continuous production.

Servo sprayer advantage for die casting machine

- Improved coating accuracy and stability

- Reduced maintenance costs and failure rates

- Enhance production efficiency of servo sprayer advantage

- Extended mold life of servo sprayer advantage

- Environmental protection of servo sprayer advantage

Improved coating accuracy and stability

- The servo spraying system, driven by servo motors, is able to achieve extremely high positional accuracy and stable movement, thus ensuring the accuracy and consistency of the spraying process.

- This high-precision spraying reduces casting defects and improves casting quality.

Reduced maintenance costs and failure rates

- Since the servo sprayer system is integrated with the control system of the die casting machine, no additional PLC is required for maintenance, simplifying maintenance.

- In addition, the servo sprayer advantage has a low-maintenance design that improves equipment reliability and reduces downtime.

Enhance production efficiency of servo sprayer advantage

- The servo sprayer for die casting machine allows for quick changeover and adjustment of spraying parameters, resulting in shorter cycle times and increased productivity.

- And the servo spraying system can also optimize spraying time and position to further reduce the defect rate of castings.

- At the same time, the servo spraying system can further reduce the defect rate of the castings by optimizing the spraying time and position, which improves the overall production efficiency.

Extended mold life of servo sprayer advantage

- The servo sprayer for die casting machine can significantly extend the service life of molds by reducing thermal stress and optimizing the spraying process.

- This is particularly important for large die casting machines, which often require higher maintenance costs and more frequent mold changes.

Environmental protection of servo sprayer advantage

- The servo sprayer for die casting machine typically utilize advanced lubricants and coating technologies that reduce lubricant usage and emissions, contributing to a more environmentally friendly manufacturing process.

Key Features of servo sprayer for die casting machines

- Servo Motor Control

- Precise Fluid Delivery

- Programmable Settings

- Integration with Die Casting Machines

Servo Motor Control

- The sprayer uses a servo motor to precisely control the spray nozzle’s position and operation.

- This provides better accuracy over traditional pneumatic or hydraulic systems, enabling more uniform coverage of the mold.

Precise Fluid Delivery

- Flow rate control allows for the precise application of mold release agents.

- This can reduce material waste and ensure the correct amount of lubricant is applied, which helps in easier part removal from the mold.

Programmable Settings

- Most servo sprayers for die casting machines allow operators to program spray patterns, fluid amounts, and application timing to suit specific die-casting jobs or molds.

- This flexibility is crucial when dealing with different die sizes or part geometries.

Integration with Die Casting Machines

- Servo sprayers can be integrated with die-casting machine control systems to automate the application of

Deep Synergy and Process Optimization with Die-Casting Machines

The high performance of servo sprayers stems not only from their own inherent characteristics but also from their deep synergy with modern die-casting machines, particularly servo drive systems. This synergy enables process optimizations that are difficult to achieve with traditional systems.

A key technology is linked positioning spraying. On die-casting machines equipped with servo-driven electric mold-closing mechanisms, the system can utilize the precise servo positioning function of the moving mold plate. During spraying, the sprayer head and the moving mold plate can move in tandem, intelligently calculating and precisely stopping at the optimal spraying distance from both the moving and fixed mold cavity surfaces, eliminating the need for additional precision movement mechanisms for the sprayer head in the mold opening and closing direction. This simplifies the equipment structure, and more importantly, by partially overlapping the spraying preparation actions with the mold opening and closing process, it significantly shortens the production cycle time.

Haichen Application Case Reference: In a customer factory producing electric drive housings for new energy vehicles, Haichen’s integrated die-casting unit solved the problem of uneven spraying of deep-cavity parts. Through seamless communication between the Haichen servo sprayer and the die-casting machine’s main control system, the system automatically generates customized spraying trajectories and dosage parameters for deep ribs and heat dissipation fins based on the mold’s 3D model data, ensuring that the release agent can accurately cover every complex corner. This solution reduces the sticking rate of such complex castings by more than 70% and extends the average mold maintenance interval by 30%.

Data-Driven Management and Intelligent Applications

Modern servo sprayers have transcended their role as mere execution units, becoming key data nodes in die-casting intelligent manufacturing networks. Their core value lies in transforming the spraying process from “experience-dependent” to a standardized “data-driven” workflow.

The system’s high-precision servo control ensures that the path, speed, flow rate, and timing of each spraying operation become precisely reproducible and storable digital parameters. This allows for the creation and locking of the “optimal spraying formula” for each mold. Furthermore, advanced systems continuously record key data such as spraying consumption and execution time, providing reliable data for production cost accounting, process trend analysis, and predictive maintenance.

Haichen Application Case Reference: In the “Production Management System” deployed by Haichen for a large die-casting plant, servo sprayers are one of the key data sources. This system not only stores the spraying programs for all molds, enabling one-click mold change recall, but also assists process engineers in identifying potential problems by monitoring real-time fluctuations in release agent consumption. For example, the system once issued a warning about a slight, abnormal increase in the amount of coating applied to a specific mold. Upon inspection, it was found that a minor blockage in the local cooling water channels caused the mold temperature to rise, thus preventing a potential batch sticking defect. This data-driven management approach helped the customer steadily improve the overall yield rate by 2.5%.

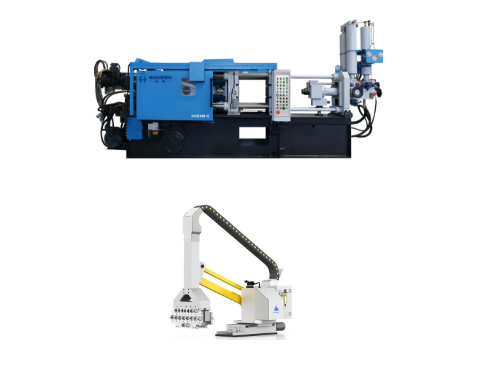

Haichen servo sprayer advantage for die casting machine

Haichen is a well-known brand that manufactures high-quality, automated solutions for die-casting processes, including servo-controlled sprayers. These sprayers help improve mold release, reduce waste, and enhance the overall efficiency of the die-casting process.

These Servo sprayer advantage make servo sprayers an essential upgrade for die casting operations looking to enhance efficiency, reduce costs, and achieve higher-quality outputs.

Servo sprayers, with their precise and controllable characteristics, have become a key component in optimizing die-casting production processes and improving overall efficiency. They not only directly improve demolding results and casting quality, but also provide a solid guarantee for production stability and sustainability through data-driven and intelligent management.