High pressure die casting application mainly applies for the automotive industry, aerospace industry, electronics industry, consumer goods and medical devices.

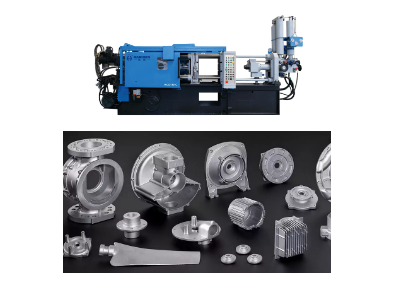

High Pressure Die Casting (HPDC) is a highly efficient metal casting process that is widely used in a number of industries to produce complex and highly accurate metal parts.

The process works by injecting molten metal under high pressure into a mold cavity, which is rapidly cooled and formed into the desired part.

This article will talk about the main areas of high pressure die casting application. It covers its wide use in the auto industry. It explains its benefits for making electronics parts and also discusses its role in industrial and consumer goods. Finally, it shows how HAICHEN die casting machines support these applications.

High pressure die casting application

- Automotive of high pressure die casting application

- Aerospace and Defense

- Electronics and Electrical Industry

- Consumer Goods

- Medical Devices of high pressure die casting application

- Industrial Equipment

Automotive of high pressure die casting application

- Engine Components: Cylinder heads, engine blocks, crankcases.

- Transmission Parts: Housings, clutch cases.

- Structural Components: Shock towers, cross beams, subframes.

- Other Parts: Wheels, brackets, housings for electronic systems.

Aerospace and Defense

- Aircraft Parts: Seats, brackets, housings for avionics.

- Defense Equipment: Radar systems, housings, and structural parts for vehicles.

Electronics and Electrical Industry

- Heat Sinks: For electronic cooling.

- Housings: Smartphone frames, laptops, and other portable device enclosures.

- Connectors and Switches: Electrical components needing high precision.

- Lighting Fixtures: LED housings and reflectors.

Consumer Goods

- Appliances: Washing machines, refrigerators, and air conditioner housings.

- Furniture: Structural frames for chairs and tables.

- Sporting Goods: Bicycle components, fitness equipment parts.

Medical Devices of high pressure die casting application

- Medical Imaging Devices: Frames and casings.

- Surgical Tools: Lightweight yet strong handles and components.

Industrial Equipment

- Hydraulic Parts: Pumps, valves, and pistons.

- Gear Housings: Enclosures for motors and machinery.

Materials used in high pressure die casting and their applications

- Aluminum Alloys

- Zinc Alloys

- Copper Alloys

- Magnesium Alloys

Aluminum Alloys

- Common grades: A380, A360, ADC12, AlSi9Cu3, etc.

- Areas of application:

Automotive components (engine block, transmission housing)

Electronic product shell (cell phone, notebook)

Lighting equipment (LED lamp housing)

Zinc Alloys

- Common grades: Zamak 3, Zamak 5, Zamak 7, ZA27, etc.

- Areas of application:

Crafts (zipper heads, door handles)

Industrial fittings (gears, locks)

Small electronics housings

Copper Alloys

- Common grades: H59, H62 (brass), bronze, etc.

- Areas of application:

Plumbing fittings

Electrical connectors

High-end mechanical components

Magnesium Alloys

- Common grades: AZ91D, AM60B, AM50, etc.

- Application Areas:

Automotive parts (steering wheel skeleton, dashboard bracket)

3C products (laptop, cell phone housings)

Aerospace and medical equipment

The advantage of high pressure die casting application

- Automotive: Lightweight, strong, and high-quality components for engines and structural parts.

- Electronics: Intricate casings with excellent thermal properties.

- Aerospace: High-strength lightweight parts for aircraft.

Haichen High Pressure Die Casting

Case: New Energy Vehicle Battery Box Production

A parts maker uses a HAICHEN 880-ton cold chamber machine to make aluminum battery box housings. The part is large (about 1.5 meters long) and complex. It needs very high sealing and strength to protect the battery. The stable, high clamping force and precise injection control of the HAICHEN machine ensure full forming, accurate size, and dense internal structure. The parts pass strict leak tests.

Key Technology Support: The real-time injection control system and stable clamping system of HAICHEN machines are key. They ensure that in this high pressure die casting application for large, complex thin-wall parts, the metal fills the mold smoothly and quickly with good quality. The efficient hydraulic and electric systems ensure stable continuous production.

Haichen Machinery is a manufacturer that specializes in advanced die-casting equipment, offering solutions for various industries, including automotive, electronics, aerospace, and consumer goods. If there is any need, please come to consult us.

High-pressure die casting has become an important means of manufacturing complex metal parts due to its high production efficiency, excellent dimensional accuracy and surface finish, and is widely used in many industries such as automotive, aerospace, and electronics.