The die casting machine conveyor price range is between 300-1000USD.It plays an important role in industrial production and has a wide range of types and applications with different prices for different materials.

Common types of die cast metal product conveyor belts

- PA belt conveyor

- CP belt conveyor

- CPT belt conveyor

- Chain conveyor

- Mesh belt conveyor

- Modular belt conveyor

- Screw conveyor belt

PA belt conveyor:

Suitable for products that need to be conveyed in high temperature environments, such as metal products with temperatures over 130°C.

The price range of this die-casting metal product conveyor is between 300-600USD.

CP Belt Conveyor:

Mainly used in conjunction with die casting units to handle aluminium or zinc alloy products.

The price range of this die cast metal product conveyor is between 400-600USD.

CPT Belt Conveyor:

Widely used adjacent to injection moulding machines (IMMs) to pick up products with gates and transport them to the separator.

The price range of this die-cast metal product conveyor is between 600-900USD.

Chain conveyor:

This type of conveyor is suitable for applications where heavy loads need to be borne, such as die-casting cooling and assembly lines in the food industry.

The price range for this type of conveyor for die cast metal products is between 200-500USD.

Mesh belt conveyor:

Mesh belt conveyors can divide into various types according to different weaving methods and materials, such as B-type, G-type, DB-type and so on.

The price range of this kind of die-cast metal product conveyor belt is between 400-800USD.

Modular Conveyor Belt:

These conveyor belts are for situations where conventional belts cannot fit, such as sliding, unsatisfactory length-to-width ratios or lateral forces.

The price range of this die-cast metal product conveyor belt is between 800-1000USD.

Spiral Conveyor Belt:

Spiral conveyor belts convey material through a spiral conveyor belt, which has a high conveying capacity and is suitable for applications where high conveying capacity is required.

The price range of this type of die cast metal product conveyor belt is around 1000USD.

Each type of die-cast metal product conveyor belt has its own unique characteristics and applicable scenarios, and choosing the right type of conveyor belt is crucial to ensure the efficient, safe and economic operation of the material handling system.

In practice, the type of conveyor belt should be determined by the material characteristics, working environment and specific application requirements to optimise operations and increase productivity.

Reasons for price differences in die cast chain conveyor belts

Die casting chain plate conveyor belt price difference is due to many aspects of factors such as:

- Material quality and type

- Specification and configuration

- Degree of customisation

- Market supply and demand

- Technology and function

- Suppliers and brands

- Production environment and use demand

Material quality and type:

The material quality of die-casting chain conveyor directly affects its price.

For example, the use of high-strength special steel will increase the cost, while ordinary low carbon steel plate is relatively cheap.

In addition, the price of stainless steel chain conveyor belt is usually higher than carbon steel chain conveyor belt.

Specification and configuration:

Different models and specifications of chain conveyor have different prices due to their different design parameters.

Heavy duty chain conveyor has higher production cost due to its larger size and heavier weight, so the price is also higher.

In addition, specifications such as the thickness, width and colour of the conveyor belt will also affect its price.

The degree of customisation:

Customised production requires more investment in R&D, design and manufacturing resources, which leads to higher manufacturing costs.

Therefore, the price of customised chain conveyor is usually higher.

Market supply and demand:

The supply situation and demand in the market will also affect the price.

Certain models of chain conveyors may be in short supply due to fewer suppliers, resulting in higher prices.

Technology and Function:

The application of intelligent technology improves the reliability of the equipment, but it also increases the cost of the equipment.

The application of real-time sensor monitoring technology improves the intelligence level of the equipment, which increases the price.

Suppliers and brands:

The purchase price of different suppliers varies, which is related to the supplier’s scale, brand influence and market positioning, Haichen as a well-known brand of die-casting equipment can provide you with excellent cost-effective price of conveyor belts.

Production environment and use requirements:

Chain conveyor is using in different production environments.

High temperature, high humidity and other harsh environments require higher wear resistance, which will also affect its price.

The price difference of die casting chain conveyor belt is the result of a variety of factors, including the quality of materials, specifications and configuration, the degree of customisation, market supply and demand, technical features and supplier brands.

You should consider these factors comprehensively when making your choice to ensure that you purchase a cost-effective product.

What are the price features of die cast mesh belt conveyor

There are 6 main price features of die cast mesh belt conveyor:

- Price range and influencing factors

- The influence of materials and manufacturing process

- Market supply and demand

- Customised demand

- Technical parameters and performance requirements

- Industry standards and quality requirements

Price range and influencing factors

Die cast mesh belt conveyors have a wide price range, ranging from a few hundred dollars to thousands of dollars.

The exact price depends on factors such as the specifications and configuration of the equipment, as well as the quantity purchased.

The influence of materials and manufacturing process

The material selection and manufacturing process of die-cast mesh belt conveyors can have a significant impact on their price.

Such as bridge conveyor due to its heavy equipment characteristics, need more high-end technology and professional personnel involved, so the price is higher.

Market supply and demand

Market supply and demand also have a significant impact on the price of die-cast mesh belt conveyors.

Certain models of conveyors may have higher price due to strong market demand, while other models pricing lower due to ample supply.

Customisation requirements

Die-cast mesh belt conveyors are usually customised products, designed and manufactured according to the specific needs of the customer.

As a result, different customer needs may result in different prices.

Prices for non-standard custom conveyors can run into the thousands of dollars or more.

Technical parameters and performance requirements

Technical parameters such as supply voltage, load current, and action force also affect the price of die cast mesh belt conveyor.

These parameters determine the performance and applicability of the equipment, which in turn affects its market pricing.

Industry standards and quality requirements

Industry standards and quality requirements also have an impact on the price of die cast mesh belt conveyors.

For example, products that comply with high levels of protection may command a higher price, as they require more complex manufacturing processes and materials.

The price characteristics of die cast mesh belt conveyors are mainly influenced by material selection, manufacturing process, market demand, customisation requirements, technical parameters and industry standards.

When selecting a die cast mesh belt conveyor, these factors need to be considered to determine the most appropriate configuration and price.

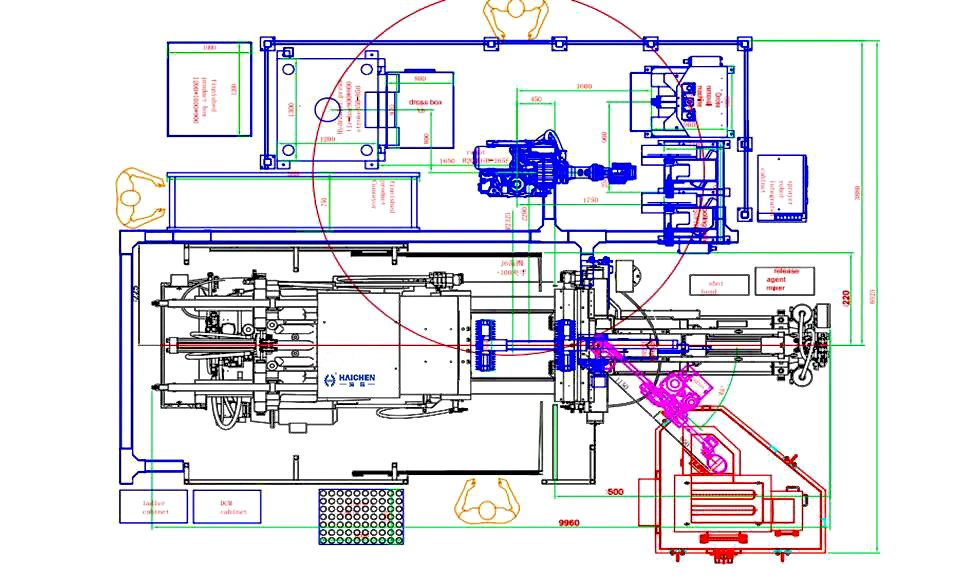

Haichen customises die casting machine conveyor at all price points

The price of customised Haichen die casting machine conveyor belts involves a number of aspects, including size, material and processing methods.

Prices for conveyor belts are usually base on a square metre basis, which means that when customising they can be made to the right size and material to suit your needs.

When customising a conveyor belt, Haichen will need to consider different processing methods to meet specific needs.

For example, skirt baffle belts are required for slope climbing, guide strips are processed for runaway prevention, and guide strips are required for anti-slip surfaces.

These different processes can be adapted to suit different conveying requirements to ensure safety, increase productivity and extend the life of the machine.

The price of a die casting machine conveyor belt is usually bulid up multiplying its dimensions (length*width) by the price per square metre.

In addition, joints are free when customising conveyor belts, so customisation is not expensive and guarantees the quality of the product and the quality of the finish.

The customisation of die casting machine conveyor belts can be done according to specific needs, including the choice of size, material and processing method, while the price is mainly based on square metres.

By choosing and customising a conveyor belt, you can be sure that it will be efficient and reliable in practice.

Welcome to contact us by email, we will provide the most cost-effective die casting machine conveyor belts.