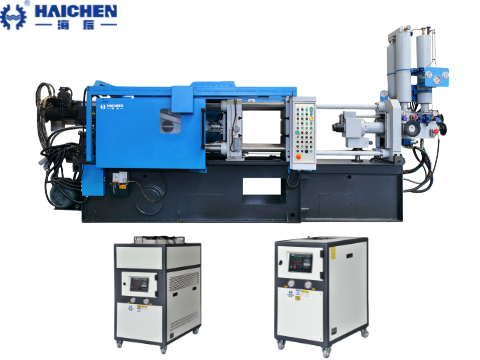

Die casting chiller advantages include improving mold and casting quality, improving production efficiency and reduce consumption, etc.

The basic function of industrial chillers in die-casting machines is to remove the heat generated by the die-casting machine and molds through circulating cooling water, maintain the equipment within a suitable working temperature range, and thus improve production efficiency and product quality.

The chiller can accurately control the temperature of the cooling water, achieve precise control of the mold temperature, extend equipment life, reduce thermal stress, wear and corrosion. In addition, chillers can effectively shorten the solidification time of castings, reduce scrap rates, and extend the service life of molds. During the die-casting process, the chiller transfers heat from the mold through an internal and external circulation system, ensuring the stability of the production process and product quality

Die casting chiller advantages mainly reflected in the following six detailed aspects:

- Improve mold life and casting quality

- Energy saving and water saving

- Improve production efficiency

- Environmental performance

- Energy saving and consumption reduction

- Improve equipment stability

Improve mold life and casting quality

During the die casting process, it has hot chamaber and cold chamber die casting. The mold is subjected to high temperature and high pressure environment. That prones to cracking, affecting the surface quality of the casting and the service life of the mold.

Hot chamber die casting: The metal and injection unit are in the same heating chamber. Suitable for low-melting-point alloys, it offers high circulation speed and relatively low pressure, but has greater limitations regarding material corrosion.

How does hot chamber die casting work? Hot chamber die casting achieves high efficiency, high precision, and is suitable for mass production of low-melting-point alloys by directly storing molten metal in a hot chamber inside the machine and using a high-pressure piston to rapidly inject the metal into a cooling mold.

Cold chamber die casting: The metal is heated in a separate furnace and then poured into a cooled injection tube, which is then injected at high speed into a mold by a piston. Suitable for high-melting-point alloys, it allows for higher injection pressure and thinner wall thicknesses, but has longer circulation times and higher energy consumption.

The difference between hot chamber and cold chamber die casting determines the different application scenarios for the two processes in terms of material selection, production scale, cost, and product characteristics.

By using die casting machine industrial chiller for effective cooling can improve this problem.The correct use of cooling water has a great impact on production efficiency, casting quality and mold life.

Thermal stress and thermal fatigue

Periodic changes in mold temperature can cause thermal stress, leading to thermal fatigue cracks. The greater the temperature fluctuation, the higher the thermal fatigue load, ultimately leading to surface cracks and peeling of the mold, shortening the mold life. For example, drastic changes in mold temperature during the die-casting process can cause cracks or fissures on the surface of the mold, significantly reducing its lifespan .

Thermal equilibrium and heat conduction

The control of mold temperature directly affects the thermal equilibrium state of the mold. Excessive or insufficient mold temperature can disrupt thermal balance, leading to a decrease in casting quality and a shortened mold lifespan. For example, a mold temperature that is too low can cause condensation on the surface of the casting and form defects, while a temperature that is too high may cause shrinkage depressions or bubble defects [43]. In addition, the uniformity of mold temperature is crucial for heat conduction, and uneven temperature distribution can lead to stress concentration, further shortening the mold life.

Thermal damage of mold materials

High temperature operation can accelerate the wear and degradation of mold materials, especially aluminum alloy die-casting molds. Prolonged exposure to high temperatures can accelerate the thermal cracking and erosion of molds. At the same time, excessive mold temperature can also lead to incomplete evaporation of the release agent, forming an low-density film and increasing the risk of mold sticking.

Mold preheating and cooling

Mold preheating is an important measure to extend its lifespan. Preheating can avoid thermal shock caused by the rapid cooling of molten metal and reduce the occurrence of surface cracks on the mold. For example, preheating the mold to 180-230 ℃ and performing 3-6 no-load cycles can effectively extend the mold life. Meanwhile, the design of the cooling system is crucial for the uniform control of mold temperature, and a reasonable layout of cooling channels can reduce temperature gradients and lower thermal stress.

Improving casting quality

Surface defect control

When the mold temperature is below 130 ℃, the metal liquid solidifies prematurely, resulting in cold insulation and flow patterns; When the temperature is above 300 ℃, it will cause surface bubbles and mold sticking. The chiller ensures uniform temperature on the mold surface through zone cooling (such as point cooling structure), reducing the porosity of thin-walled parts (<2mm) by 70%.

Dimensional accuracy guarantee

Temperature fluctuations result in a difference of ± 0.1mm in mold expansion. Under constant temperature conditions (220 ± 10 ℃), the dimensional tolerance of castings remains stable at CT8 level, and the assembly qualification rate of automotive components has increased to 99.2%.

Improve material properties

Grain structure optimization

The chiller reduces the solidification time by 30%, promotes the refinement of aluminum alloy grains to ≤ 50 μ m, and increases tensile strength by 15-20%.

Reduction of internal defects

Stabilize the mold temperature to avoid concentration of shrinkage stress, reduce the porosity inside the casting from 8% to 1.5%, and increase the X-ray inspection qualification rate by 40%.

Energy saving and water saving

The design of industrial chillers usually includes efficient spot cooling systems, such as RO reverse osmosis water treatment devices, water-cooled chillers, etc.

These devices can effectively control the mold surface temperature, and achieve water-saving and environmental protection effects.

Variable frequency speed regulation and dynamic load matching

Modern industrial chillers use frequency conversion control technology to match the actual heat load of the die-casting machine by adjusting the compressor speed in real time. Compared to traditional fixed frequency units, it can reduce 25% -40% of ineffective power consumption. For example, when the die-casting machine is in standby or low load state, the compressor automatically slows down to avoid energy waste.

Design of Efficient Heat Exchange System

Microchannel evaporator: adopting a three-dimensional fin structure, the thermal contact area is increased to 1.8 times that of traditional shell and tube type, significantly enhancing heat transfer efficiency.

Hydrophilic aluminum foil surface treatment: accelerates the dripping speed of condensed water by 30%, reduces water film thermal resistance, and improves phase change heat transfer efficiency.

Heat recovery device: recovers the waste heat generated during the die-casting process (up to 30% -80% of the cooling capacity), which is used for preheating process water or workshop heating, achieving energy cascade utilization.

Optimization of Intelligent Control System

The fully automatic microcomputer controller adjusts the cooling water flow and temperature in real time according to the mold temperature, avoiding energy redundancy caused by overcooling or insufficient cooling. The remote monitoring function further optimizes the operation strategy and reduces human operation errors.

In addition, the circulating water cooling device can significantly reduce industrial water consumption and save a lot of water resources.

Improve production efficiency

By optimizing the design of the cooling water circuit, the temperature of the injection chamber can be effectively reduced.

Stable cooling effect

Industrial chillers can provide stable cooling effect, maintain the normal operating temperature of equipment, and thus improve production efficiency. In high temperature environments, equipment is prone to overheating, leading to equipment failure or shutdown. Industrial chillers effectively reduce equipment temperature and maintain normal equipment operation by cooling the equipment.

Efficient energy consumption control

Industrial chillers adopt advanced energy-saving technologies, which can control energy consumption while reducing equipment temperature. Compared to traditional cooling equipment, industrial chillers can more efficiently utilize energy, reduce energy waste, and lower production costs.

Accurate temperature control

Industrial chillers can precisely adjust the temperature during the production process, ensuring product quality and process stability. This precise temperature control helps to improve product qualification rate and quality stability.

Equipment maintenance and operation

Poor operating habits and neglect of maintenance can seriously affect the operational efficiency of industrial chillers. For example, increasing water flow to obtain more cooling water can lead to equipment overload, reducing efficiency and lifespan. In addition, regular inspections and recording of equipment operating parameters are necessary to promptly detect refrigerant leaks, pipeline scaling, and other issues, reducing the occurrence of failures and ensuring stable equipment operation

Moreover, the occurrence of locking failures can be reduced. Thus it can improve the service life and production efficiency of the injection chamber.

Environmental performance

The design of industrial chiller focuses on environmental protection.

For example, the design of the W-type cast aluminum water-cooling machine base can supply leak-proof and water-proof. With the reliable structure, chiller help to reduce environmental pollution.

The impact of industrial chillers on greenhouse gas emissions depends on their refrigerant type, energy efficiency level, and whether energy-saving technologies are used. The following is a comprehensive analysis:

Refrigerant selection

The types of refrigerants used in industrial chillers have a significant impact on greenhouse gas emissions. For example, the use of high global warming potential (GWP) refrigerants such as HCFC-22 can lead to higher greenhouse gas emissions

Using low GWP refrigerants (such as HFO, R-32, R-410A, etc.) or natural refrigerants (such as CO ₂, NH3) can significantly reduce greenhouse gas emissions

For example, the new chiller launched by Trane uses R-513A refrigerant, which has a GWP value 55% lower than traditional R-134a.

Energy efficiency improvement

Efficient and energy-efficient chillers can significantly reduce energy consumption, thereby lowering greenhouse gas emissions. For example, compared to traditional screw chillers, magnetic levitation variable frequency centrifugal chillers have an energy efficiency improvement of over 20%. In addition, the variable frequency chiller achieves on-demand cooling by adjusting the compressor speed, and the energy-saving effect can reach 10%~50%.

Heat recovery technology

The heat recovery chiller recovers waste heat from the refrigeration process to achieve energy reuse, thereby reducing energy consumption and greenhouse gas emissions. For example, a heat recovery chiller can use the heat generated by the compressor for heating or hot water preparation, further improving energy efficiency. This technology not only reduces energy demand, but also reduces dependence on traditional energy, which helps achieve low-carbon development.

Energy saving and consumption reduction

Industrial chillers focus on energy saving and consumption reduction in design.

For example, the servo cold chamber die-casting machine uses servo motors and full closed-loop control technology, which can significantly reduce energy consumption and improve production efficiency.

Optimizing operating parameters

By adjusting the load ratio of the chiller unit to operate between 70% and 80%, power consumption can be reduced while improving energy efficiency. In addition, appropriately increasing the evaporation temperature and reducing the condensation temperature can also improve energy utilization efficiency.

Adopting efficient equipment

Select a chiller with high energy efficiency ratio (EER) and use frequency conversion technology to adjust the operating frequency according to actual cooling needs, thereby achieving energy conservation and consumption reduction. Meanwhile, choosing environmentally friendly refrigerants and high-efficiency compressors can also help reduce energy consumption.

Regular maintenance

Regularly clean the heat exchanger of the chiller to prevent dirt and dust from affecting heat transfer efficiency. Regularly check the refrigerant pressure and electrical components to ensure optimal equipment operation.

Intelligent control system

Install an intelligent control system to adjust the operation mode of the industrial chiller according to actual production needs, achieve precise control, and reduce energy waste.

Optimization system design

Multiple chiller units are used in combination for operation, and the number of equipment operations is flexibly adjusted according to actual cooling needs to reduce energy consumption. At the same time, a cold storage system is set up to store cold during periods of low power load and release cold during peak periods, achieving energy conservation and consumption reduction

In addition, by adopting frequency conversion control technology and embedded real-time controllers, can reduce power consumption. So it can achieve the purpose of energy saving and consumption reduction.

Improve equipment stability

Industrial chillers focus on equipment stability and safety in design.

For example, the horizontal cold chamber die-casting machine uses high-strength materials and advanced hydraulic system design. This design ensure the stability and reliability of equipment operation.

There is a close relationship between the cooling efficiency of industrial chillers and equipment stability.

Firstly, industrial chillers maintain stable operating temperatures through refrigerant circulation and water cooling principles, thereby improving product quality and production efficiency.

Secondly, its high efficiency, stability, and reliability enable it to provide continuous and stable cooling capacity, with uniform cooling effect, which is crucial for industrial processes.

In addition, industrial chillers use advanced refrigerants and intelligent control technology to improve energy efficiency and user experience, providing more reliable cooling solutions for industrial production.

Die casting machine industrial chiller has significant advantages in improving mold life, casting quality, production efficiency, environmental protection performance, energy saving and consumption reduction, etc. Die casting chiller advantages make industrial chiller an indispensable and important equipment in die casting production.