Types of industrial robots:

- Intelligent foundry robot

- Heavy-duty intelligent robots

- Six-axis robot

- Linear robots

- Multi-axis robot

- Servo robots

- Multi-axis robot

- Special die-casting robot

- Intelligent Grinding Robot

In the foundry industry, industrial robots can be used for a variety of different tasks, including casting, painting, cleaning, cutting, and polishing.

Industrial robot——Intelligent foundry robot

The intelligent foundry robot uses advanced artificial intelligence technology to monitor key parameters.

Such as temperature and pressure in the casting process in real time to ensure production safety and casting quality.

Industrial robot——Heavy-duty intelligent robots

The new heavy-duty intelligent robot has a handling weight of up to 1000kg and a larger range of motion.

And adopts a new mechanical design to make the robot more compact and has a larger range of motion.

Industrial robot——Six-axis robot

These robots have high flexibility and precision, making them suitable for die casting production.

Flexible, fast and precise, it is suitable for the production of a wide variety of components in confined spaces.

Industrial robot——Linear robots

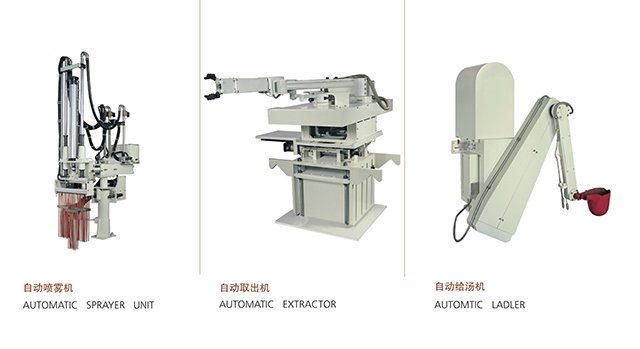

Linear robots are between industrial robots and manipulators, and are suitable for die-casting production needs such as spraying, picking, cooling, and palletizing, and are cost-effective.

Industrial robot——Servo robots

Servo robotics is also available in die casting automation.

For example, servo picking robots can form fully automatic production with die-casting machines and spraying machines to improve production efficiency.

Industrial robot——Multi-axis robot

Six-axis industrial robots, suitable for multi-degree-of-freedom operations in complex applications, can meet the needs of flexible production.

Industrial robot——Special die-casting robot

The special die-casting series robots have high protection characteristics such as high temperature resistance, dust resistance, and high humidity resistance.

And are widely used in harsh environments such as die-casting, hot forging, grinding and deburring.

Industrial robot——Intelligent Grinding Robot

The robot can flexibly walk on the track and polish large steel castings in various postures, showing a high level of intelligence.

This robot not only improves the grinding efficiency, but also reduces the labor intensity and environmental pollution caused by manual grinding.

Advantages of industrial robots

- Improve productivity and accuracy

- Enhance complex molding capabilities

- Improve security

- Energy saving and environmental protection

Improve productivity and accuracy

The robot is able to achieve high-precision repetitive positioning, which improves production efficiency and product quality.

During pouring operations, the robot can execute the program with consistent movements, optimize the quality of the casting, and reduce cavitation and porosity.

The application of robots in soup, spraying, pick-up and other links makes the control system of the die-casting machine.

And peripheral equipment more and more integrated, and realizes the automatic and unmanned operation of the whole process.

Enhance complex molding capabilities

Robotics enables complex molding tasks that are difficult to cope with with traditional methods.

Such as the manufacture of fine design, multi-bending, and highly geometrically complex parts.

The servo sprayer and pick-up machine has a six-axis rotation function that can adapt to the spraying requirements of complex molds, improving the consistency and reliability of operation.

Improve security

Robots are manufactured using heat-resistant materials.

Eliminating the need for workers to be exposed to high temperatures for long periods of time and improving workplace safety.

Cobots are able to work safely in close proximity to humans, reducing the risk of accidents.

Energy saving and environmental protection

Automating the die casting process can improve energy efficiency and reduce energy consumption.

Significant power and cost savings can be achieved by shutting down machines when not in use through an automated system.

The core functions of die-casting industrial robots

Part retrieval and handling:Remove high-temperature castings from the mold and transfer them to the next process.

Pouring (feeding soup) :Precisely control the injection of molten metal into the mold.

Demolding spray:Spray demolding agent on the surface of the mold to ensure the smooth demolding of the casting.

Post-processing:including deburring, cutting the gate, polishing, marking, etc.

Quality inspection:Conduct integrity checks on castings in combination with the visual system.

Haichen industrial robots

Haichen’s industrial robots help foundries improve production efficiency and product quality in die casting production.

And also reduce the need for manual operation through automation, thereby reducing production costs and improving safety.