There are various types of die casting machine Extractors, mainly including the following:

- Servo manipulator

- Five-link Extractor

- Industrial robotic arm

- Automatic die-casting Extractor

- Clamp-on Extractor

- Customized pick-up manipulator

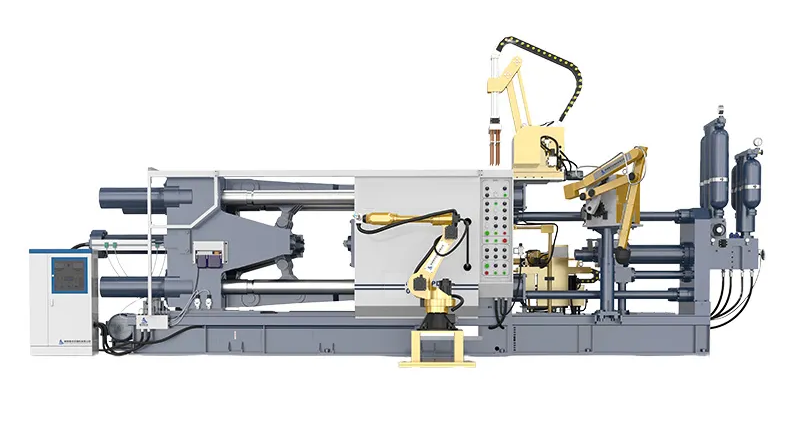

In the mass production of thin-walled non-ferrous metal parts, molten metal is injected into metal molds at high speed and high pressure.

To ensure that the components can be easily demolded and maintain surface quality, a mold release agent is sprayed on the mold and lubricated at key positions.

Then, after the casting is completed, use the piece pick-up hand to pick it up.

The size of the required pick-up hand depends on the size and design of the machine.

Whether it is a cold chamber system or a hot chamber system.

Servo manipulator

This type of Extractor is usually driven by a multi-axis servo system, which has the characteristics of high precision, high speed and flexibility.

For example, some models of pick-up manipulators include six-axis robots.

Which can realize complex movements and can be linked with die-casting machines, sprayers and other equipment to achieve fully automatic production.

Five-link Extractor

This Extractor is usually used in zinc alloy die-casting machines.

Suitable for smaller or irregular workpieces, with a five-link mechanism to achieve gripping and placement.

Industrial robotic arm

Six-axis robotic arm is a common type of Extractor with a large working range and flexibility.

Suitable for a variety of die casting scenarios, including loading and unloading, injection molding, die casting, etc.

Fully automatic die casting Extractor

This type of equipment usually integrates a variety of functions.

Such as spraying, trimming, etc., to automate the whole process from taking out the casting to placing it on the conveyor belt.

Gripper type Extractor

This kind of Extractor grabs the casting through the fixture.

Which is suitable for the workpiece with regular shape, and has the characteristics of simple structure and convenient operation.

Customized pick-up manipulator

According to different production needs, manufacturers can provide customized pick-up manipulators to meet specific material and process requirements.

Each of these Extractor types has its own characteristics and is suitable for different die casting scenarios and needs.

which can effectively improve production efficiency and automation level.

Advantages of Extractors

The die-casting machine extractor has many advantages, mainly reflected in the following aspects:

- Improve production efficiency

- Adaptable

- High degree of automation

- Versatility

- High safety

Improve production efficiency

The die-casting machine Extractor can complete the pick-up operation quickly and accurately.

Reduce the waiting time and operator errors in the production process, and thus significantly improve production efficiency.

For example, the Extractor with servo control and PLC control system can achieve high-precision positioning and clamping.

Adaptable

The Extractor is designed to be flexible and able to adapt to different sizes and shapes of castings.

For example, some Extractors use a four-link mechanism

Which can easily remove the product in a small space and can be adapted for the production of complex molds.

In addition, manufacturers can adjust the trajectory of the picker hand through programming to adapt to different workpieces and production requirements.

High degree of automation

Extractors usually have intelligent control systems that can achieve fully automatic operation without manual intervention.

This not only improves the stability and consistency of production, but also reduces labor costs and the risk of workplace injuries.

Versatility

Modern die casting machine Extractors are not limited to simple pick-up actions

But can also integrate other functions such as slag removal bag, spray, trimming, etc., to further improve the automation level and efficiency of the production line.

Easy maintenance

Many Extractors use high-strength materials and advanced drive systems

Such as servo motors and gear units, which eliminate the need for frequent oil changes and are relatively simple to maintain, extending the life of the equipment.

High safety

The Extractor is usually equipped with a variety of safety protection functions

Such as anti-collision devices and emergency stop buttons, to ensure safe and reliable operation.

The Die Casting Machine Pickup Arm is an indispensable piece of equipment for modern die casting production lines by improving productivity, adaptability, high automation, versatility, ease of maintenance, and ensuring safety.

The function of the extractor

The integrated functions of the automatic die casting picker include the following aspects:

- Casting extraction

- Product integrity inspection confirmation

- Die-casting cooling

- Slag bag

- Fine blanking

- Grinding and deburring

- Product Conveying

- Spraying

Casting extraction

The six-axis robot can flexibly perform secondary operations to quickly and accurately remove castings from the mold and place them in the designated position.

The robot system automatically completes functions such as product clamping, detection, water-cooled positioning, hydraulic positioning and transfer table positioning through different attitude changes.

Product integrity inspection confirmation

During the pick-up process, the robot system can carry out product integrity inspection to ensure product quality.

Die-casting cooling

Integrated cooling systems, such as cooling fans and lifting cooling water tanks, ensure that castings are cooled immediately after removal.

Slag bag

Remove the slag bags on the surface of the castings to improve their quality.

Fine blanking

The robot system can perform fine blanking operations to further improve the accuracy and surface quality of castings.

Grinding and deburring

The robot grinding and deburring device is used to remove burrs from the surface of the casting and improve the overall quality of the casting.

Product Conveying

The robot system can transport the processed castings to the designated location to achieve a fully automated production process.

Spraying

In addition to picking, the robot system can also be used with a spraying device to coat castings to meet different surface treatment needs.

Data recording and monitoring

Data recording and real-time monitoring of the entire production process ensure the transparency and traceability of the production process.

Haichen Extractors Application

The application examples of Haichen extractors cover a wide range of areas and demonstrate the wide range of applications of automation technology in die casting production.

For details, please refer to Haichen’s website.

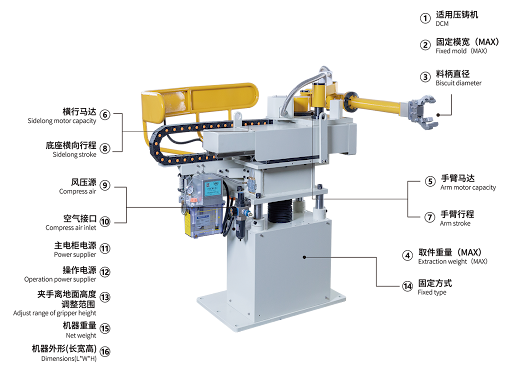

Robot pick-up application

The manipulator is used to pick up parts from the die-casting machine with a compact arm structure

And the pick-up claw is designed to be extended, which can complete the pick-up operation even in confined spaces.

In addition, the robot can continue to remove the slag bag, air cooling and edge trimmer loading the workpiece after picking.

Machine automation pick-up case

Haichen can also provide customers with die-casting pick-up robot application solutions.

Including industrial robots, pick-up fixtures, bases, spraying mechanisms and automatic receiving lines.

The robot acts immediately after the completion of die-casting, completes operations such as picking, spraying release agent.

And mold clamping production, and puts the workpiece into the receiving line to achieve circular production.