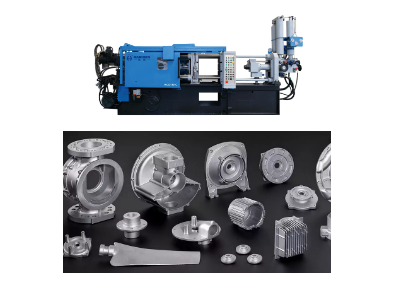

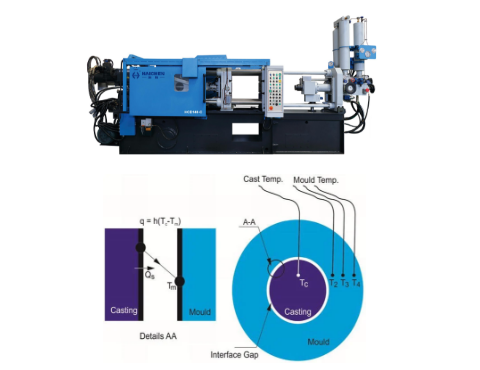

Heat transfer in die casting refers to the heat exchange process between the liquid metal and the mold during the die casting process.

This process has a significant impact on the quality and performance of the casting.

In the die casting process, liquid metal fills the mold cavity at high speed and solidifies under high pressure to form a casting.

The interfacial heat transfer behavior has a significant effect on the microstructure and mechanical properties of castings.

Therefore, Haichen controls the temperature of the die casting mold by reasonably arranging the cooling pipeline, which is crucial for the performance and service life of the mold.

Heat Transfer Measurement Method

Haichen conducted specific measurements of the interface heat transfer coefficient (IHTC) during the die-casting process through a variety of experimental and computational methods:

- Finite Element Analysis and Optimization Methods

- Experimental design and numerical simulation

- Vacuum-Assisted High Pressure Die Casting (HPDC)

- Iterative formulas

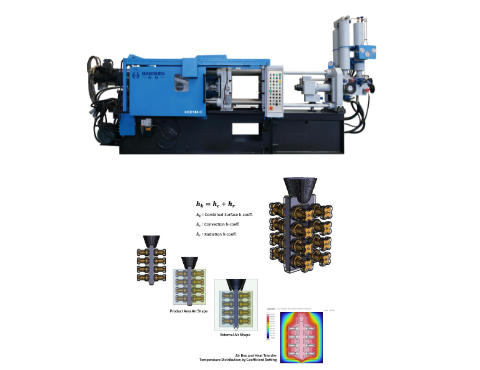

Finite Element Analysis and Optimization Methods

Finite element analysis (FEM) combined with optimization method (FEM-OPT) was used to calculate IHTC.

In this method, the quantitative relationship between the heat transfer coefficient of the water-cooled interface of aluminum alloy.

And the change of temperature is realized through numerical simulation iterative calculation and automatic optimization.

Experimental design and numerical simulation

By designing the mold and casting process, accurately installing the pressure sensor and temperature measurement unit.

And carrying out extrusion casting experiments.

Establish a set of accurate measurement methods for mold temperature and interfacial pressure.

Discuss the performance of IHTC under different material and process conditions using a circular test model and Beck’s nonlinear estimation method.

Vacuum-Assisted High Pressure Die Casting

In the HPDC process, 18 thermocouples record time-varying temperature data on molds and castings.

And the IHTC and heat flux were calculated by program using the finite difference method.

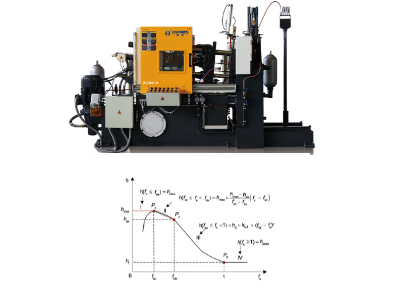

Iterative formulas

In die casting, as the solidification process progresses, the casting gradually reaches the liquid phase temperature, at which point the mold temperature also rises significantly to the maximum temperature.

Subsequently, a solid film is formed on the outer surface of the casting, causing the metal to shrink and create an air gap between the metal and the mold.

As the casting solidifies further, the air gap completely separates the two surfaces. Haichen believes that this is a common phenomenon in most alloys.

Because the casting releases a large amount of latent heat to the mold, its heat transfer rate is very high, and the casting temperature gradually approaches the solid-phase temperature (<sub>Ts</sub>) of the alloy.

Air gaps play an important role in various factors that influence the solidification process and significantly affect the interfacial heat transfer coefficient (IHTC).

Based on the least squares method and the thermal conductivity model, the iterative formula of IHTC is given.

A computer program completes the calculation of IHTC.

Improve heat transfer efficiency

Reducing the air gap between free interfaces to improve heat transfer efficiency is a complex and multifaceted task in die casting mold design.

- Vacuum-assisted technology

- Optimize mold temperature control

- Efficient in-mold cooling system

- Exhaust valve design

- Increases the heat dissipation surface

- Optimize the sprue system

- Use additives and lubricants

Vacuum-assisted technology

Vacuum-assisted technology can significantly increase the interfacial heat transfer coefficient (IHTC) of castings.

Reduce the porosity of castings, and thus improve heat transfer efficiency.

Haichen discovered that vacuum assistance can effectively reduce the porosity and particle size in castings.

Thereby improving the mechanical properties of castings.

Optimize mold temperature control

Mold temperature has an important influence on the heat transfer behavior in the die casting process.

By using high-performance multi-zone temperature control equipment.

Precise control of the mold temperature can be achieved to optimize the heat transfer process.

Preventing the alloy liquid from passing through the gap and affecting the normal production.

Efficient in-mold cooling system

The non-destructive heat dissipation process of the mold is achieved through the efficient in-mold cooling cycle.

Which can replace the traditional external cooling method.

This design method not only reduces thermal stress and impact on the die steel.

But also ensures an optimal temperature distribution.

For example, the integration of several independent circulation channels in the mold ensures the desired heat dissipation and even temperature distribution.

Exhaust valve design

Reasonable design of the position and width of the exhaust valve in the mold can effectively discharge the gas from the mold and reduce the formation of pores.

This can be achieved through an automated design system, which avoids iterative calculations and improves design efficiency.

Increases the heat dissipation surface

Increasing the heat dissipation surface in a specific part of the mold, such as processing the heat dissipation mesh on the forming surface of the side slide, can improve the heat dissipation efficiency.

This method not only increases the heat dissipation area.

But also improves the heat transfer efficiency by optimizing the heat dissipation path.

Optimize the sprue system

By optimizing the design of the sprue system, a fast and uniform mold filling process can be achieved.

Resulting in fewer internal defects due to air entrapment or shrinking pores.

For example, the use of a runner system that is lightweight and has an increased surface area for a specific surface area can effectively control the local temperature.

Use additives and lubricants

Using additives that help release dissolved gases during the melting process and lubricate the mold after each casting can reduce porosity tendency.

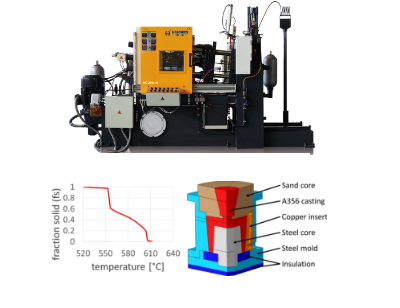

Interfacial heat transfer coefficient

Internal heat conduction (IHTC) governs the heat transfer characteristics during casting.

After workers pour molten metal into the cavity, the metal utilizes its inherent fluidity a key casting property defined as the liquid alloy’s ability to fill molds to rapidly occupy the cavity.

Consequently, this process establishes complete contact between the metal and the mold surface, thereby optimizing heat conduction efficiency.

In the early stage of solidification, the molten metal has good fluidity and the contact between the casting and the mold surface is good.

Assuming the expansion is uniform, the air gap size is measured as x, and the interinterface heat transfer coefficient is estimated as h = k/x: where k is the thermal conductivity of air (W/mK).

If all factors are not taken into account during the design process, IHTC will actually become very unpredictable.

The core factors affecting heat transfer efficiency

- Mold materials and design

- Cooling system design

- Alloy properties

Mold materials and design

Thermal conductivity: High thermal conductivity die steel (such as H13) accelerates heat dissipation.

But it is necessary to balance the coefficient of thermal expansion to avoid deformation.

For example, the thermal conductivity of H13 steel used by Haichen is about 24 W/m·K, while the thermal conductivity of copper alloy molds can reach 400 W/m·K, but the cost is higher.

Cooling system design

Channel layout: The distance from the cavity surface should be more than 25 mm to avoid local overheating. The corner should be more than 50mm to prevent cracking.

Flow control: Turbulent flow (Reynolds number > 2300) has a thermal efficiency that is over 30% higher than that of laminar flow.

Surface coating: Graphite coating adjustable IHTC.

When the thickness of the water-based graphite coating is increased by 10μm, IHTC is reduced by 15%, and the porosity of thin-walled parts is decreased.

Alloy properties

Thermal physical property difference: The peak value of IHTC in aluminum alloys (such as A380) is approximately 100 kW/m²K.

While in magnesium alloys (AZ91) it reaches 90 kW/m²K, due to the higher solidification shrinkage rate of magnesium.

Solidification behavior: In eutectic alloys (such as AlSi7Mg), a secondary peak of IHTC occurs at the end of solidification, which is caused by the exudation of solute liquid to fill the air gap.

The active control technology of heat transfer for Haichen die-casting machines

- Temperature Control Unit (TCU)

- Advanced cooling technology

Temperature Control Unit (TCU)

The mold temperature is precisely regulated through the circulation of oil/water medium (oil temperature ≤360°C, water temperature ≤160°C), and the temperature difference can be controlled within ±2°C.

It can achieve the effect of reducing the cycle time by 20%, extending the mold life by 30%, and lowering the scrap rate to less than 2%.

Advanced cooling technology

Haichen equips its die-casting machine with jet cooling technology.

Specifically, the system directs high-pressure water to impact the hot spot area, consequently increasing local cooling efficiency by 50%.