To manufacture an aluminium radiator with a Haichen die casting machine is to use high-pressure die casting for making complex cooling structures in one piece.

Aluminum radiators are efficient heat exchange devices widely use in automotive, industrial equipment, and building heating systems. They achieve temperature regulation and heat dissipation by transferring heat from the coolant (such as water or coolant) flowing through their interior to the air.

Die casting machine technology is a manufacturing process that rapidly produces high-precision, complex shaped metal parts by injecting molten metal into the mold cavity under high pressure. The basic principle is to use high pressure (usually between 150 and 1200 bar) to quickly fill liquid metal into the mold, and then cool and solidify under high pressure to form the desired casting. This process typically uses for mass production and can achieve high consistency, high surface quality, and high production efficiency.

Aluminum radiator die-casting machine is a specialized equipment for manufacturing aluminum radiators, which produces parts by injecting molten metal into the mold cavity under high pressure and rapidly cooling it. This equipment typically uses cold chamber die casting technology and is suitable for high melting point alloys such as aluminum and magnesium. Aluminum radiator die-casting machine widely use in automotive parts, consumer electronics and other fields. With the advantages of high production efficiency and dimensional accuracy.

The following are the detailed manufacture a aluminium radiator with Haichen die casting machine steps. It includes five baisc steps:

- Material selection and preparation

- Aluminum radiator mold design

- Aluminium radiator die casting process

- Cooling and demolding

- Post-processing

Material selection and preparation

- Pure aluminum

- 6063 aluminum alloy

- 6061 aluminum alloy

- 7075 aluminum alloy

Select a suitable aluminum alloy material, such as a specific aluminum alloy material with composition includes 9.0%-9.4% silicon (Si), 0.5%-0.75% copper (Cu), 0.35%-0.42% magnesium (Mg), etc. This material optimizes to have good fluidity, anti-sticking and corrosion resistance.

The mechanical and thermal conductivity parameters of different material types in aluminum radiators are as follows:

Pure aluminum

Thermal conductivity: approximately 235 W/(m · K).

Mechanical properties: The tensile strength is relatively low, usually 115 MPa, and the yield strength is also low, but it has good thermal conductivity and corrosion resistance.

6063 aluminum alloy

Thermal conductivity: approximately 210 W/(m · K).

Mechanical properties: High tensile strength, up to 290-330 MPa, yield strength of 270-300 MPa, elongation at break ≥ 12%, with good processability and plasticity.

6061 aluminum alloy

Thermal conductivity: approximately 200-230 W/(m · K).

Mechanical properties: High tensile strength, reaching over 250 MPa, yield strength ≥ 210 MPa, with good strength and thermal conductivity.

7075 aluminum alloy

Thermal conductivity: approximately 200-230 W/(m · K)

Mechanical performance: It has higher strength and wear resistance, suitable for use in high load and high temperature environments, but it is more difficult to process.

Different types of aluminum materials have differences in mechanical and thermal properties. And the selection of suitable materials need to balance base on specific application scenarios and performance requirements.

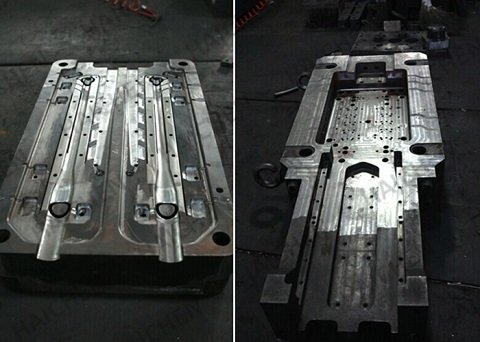

Aluminum radiator mold design

- Aluminium radiator basic structure composition

- Mold structure design

- Cooling system design

- Exhaust system design

When designing the die casting mold, you need consider the complex shape and deep cavity of the heat sink. Use Pro/E software to create a 3D model of the heat sink and design the mold cavity and core.

The mold usually made of two hardened tool steels. One for the upper mold and the other for the lower mold. These molds need to withstand high temperatures and pressures.

Aluminium radiator basic structure composition

Aluminum radiators typically compose of multiple parts. Including heat dissipation cores (made up of aluminum tubes and fins), connectors (such as flanges and joints), seals (such as O-rings), and decorative panels. The heat dissipation core is the core part responsible for heat exchange, while the fins increase the heat dissipation area to improve heat conduction efficiency.

Mold structure design

Mold structure design is the core part of mold design, which determines the strength, rigidity, and stability of the mold. When designing, it is necessary to consider the structural form of the mold, such as slender cores, complex cores, and multi insert molds, which have a direct impact on the design of the cooling system

The mold structure should be concise and clear, easy to process and maintain, while avoiding complex geometric shapes and internal structures to reduce processing difficulty and costs.

Cooling system design

The design of the cooling system need to consider the control of cooling water flow and temperature. Because it can ensure that the temperature on the mold surface is uniformly reduced without causing problems. Such as expansion or contraction.

The design of the cooling water channel should be reasonable to ensure that the water can cover the entire surface of the mold, in order to achieve the best cooling effect

In addition, the optimized design of the cooling system can accelerate the cooling speed of the product, shorten the molding cycle, and improve production efficiency.

The design of the cooling system also needs to follow some basic principles, such as the number of water holes, diameter, spacing, arrangement, and strengthening cooling in heat concentration areas.

Exhaust system design

Reasonable design of the exhaust system can reduce the generation of bubbles and improve product quality. The design of the exhaust system need to consider the exhaust requirements of the mold to ensure that the plastic is uniformly heated in the mold cavity. Avoiding product deformation, uneven shrinkage, and a decrease in appearance quality.

Aluminium radiator die casting process

- Clamping

- Injection

- Cooling&Pressure Holding

- Ejection

The aluminum alloy heats to an appropriate temperature (usually 650-700°C). And then the molten metal is injected into the mold by a aluminium radiator die casting machine. During the die casting process, the mold need preheated to above 180°C to reduce thermal shock and improve product quality.

Injection speed and pressure need adjust according to the specific material and mold design to ensure uniform filling and good molding.

Clamping

- Clean and lubricate the surface of the mold (lubricant can control the mold temperature and assist in demolding).

- The hydraulic system closes the two halves of the mold and applies locking force (to ensure that there is no overflow during high-pressure injection).

Injection

- Molten aluminum (usually 630-730 ° C) injects into the mold cavity at a high pressure of 1500-25000 psi.

- High speed filling (ensuring that the aluminum liquid fills the thin-walled teeth before solidification)

Vacuum system reduces porosity.

Cooling&Pressure Holding

Maintain pressure until solidification (to prevent shrinkage, for approximately 2-60 seconds).

Mold water cooling accelerates the formation of heat dissipation teeth (mold temperature needs to be stable at 120-280 ° C).

Ejection

After mold opening, the ejector pin pushes out of the casting to avoid deformation.

High density tooth radiators require precise protrusion design to prevent tooth breakage.

Cooling and demolding

- Cooling rate

- Mold temperature

- Cooling method

In the mold, the aluminum alloy cools rapidly and solidifies. The cooling rate can control by passing air through the internal channels of the mold. To optimize the microstructure and mechanical properties of the product. After cooling, the casting will remove from the mold using a ejector pin.

Cooling rate

Cooling rate is an important factor affecting the microstructure and properties of aluminum alloys. A higher cooling rate can suppress the formation of harmful phases, improve the ductility and mechanical properties of materials.

Mold temperature

Mold temperature has a significant impact on the material properties during the cooling process. During the die-casting process, the mold temperature should be controlled below 750 ° C to avoid excessive oxidation of alloy elements and the formation of pores

In addition, mold temperature can also affect the cooling rate and mechanical properties of castings

Cooling method

In some cases, due to the inability of cooling water to effectively cool the mold. It can use air cooling or heat pipe cooling technology. Although air cooling has a lower cooling temperature, it can evenly blow away volatile gases in the coating and reduce porosity in casting.

Post-processing

For some complex radiator structures, subsequent processing such as cutting, grinding or spraying may require to achieve the performance requirements of the final product.

Conclusion: through the above steps, high-quality aluminum radiators can efficiently produce using a die-casting machine. This manufacturing method not only enables accurate molding of complex shapes, but also ensures high strength and corrosion resistance of the product.

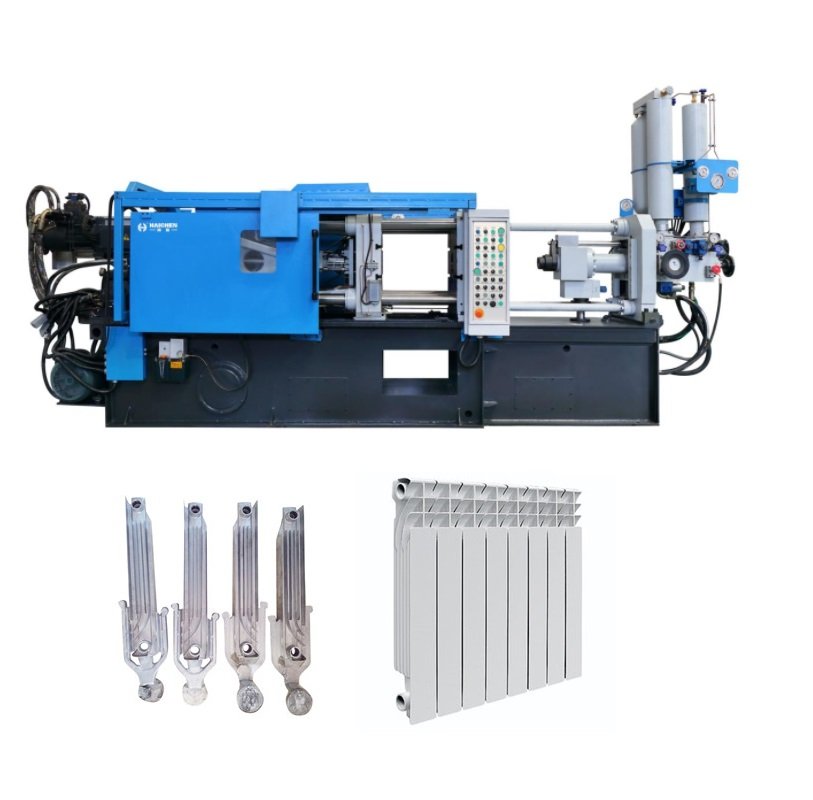

Haichen High-Pressure Aluminium Radiator Die Casting Machine

Haichen produce high pressure die casting machines with below advantages:

High Dynamic Response Shot System

The system delivers extremely high injection speeds and rapid pressurization times, ensuring that molten aluminum fills complex, densely packed thin-walled fins within milliseconds, fundamentally preventing underfill or cold shut defects.

Advanced Vacuum Die-Casting Assistance

Integrated with an efficient vacuum system, it can rapidly remove gas from the mold cavity, significantly reducing internal porosity in castings and providing process assurance for producing high-density, high-thermal-conductivity radiator blanks.

Precise real-time closed-loop control

R1: “The first mock examination” must be translated as the first mock examination.

The real-time monitoring and feedback adjustment of every stage in the die-casting process ensure stable process parameters for each mold cycle, guaranteeing consistent performance of radiators in large-scale production.

Robust Locking and Rigid Structural Design

The equipment features high rigidity and stable clamping force, capable of withstanding high filling pressure while effectively minimizing mold expansion, ensuring dimensional accuracy and structural integrity of radiators, especially large ones.