When it comes to machine selection for aluminum radiators, focus on the press type, clamping force, shot capacity, cooling system, etc.

The lightweight, high corrosion resistance, and increased thermal conductivity are reasons why aluminium radiators are extensively used in various applications.

It is important to obtain high quality and production efficiency when choosing a machine for manufacturing aluminium radiators, thus machine selection is very important.

Because of the higher production rates and the ability of handling complex designs, cold chamber die casting machines tend to be the first choice for aluminum radiator production.

This article will provide the necessary considerations that guide one in selecting the right machine for aluminum radiator manufacturing.

Type of Die Casting Machine

Cold chamber die casting machines are the preferred type for the production of aluminium radiators. Their precision in controlling the injection of molten aluminium into the die cavity ensures capture of every intricate detail, thus the structural integrity of the radiators.

Among these, cold chamber devices are said to be the best for high temperature alloys, especially aluminum because they remove the added danger of safely containing the molten metal.

Also, cold chamber machines enable selection of different alloys and have the advantage of accommodating parts that are more complex and larger in size making them suitable for the manufacturing of advanced high precision parts such as aluminum radiators.

Clamping Force

During die casting, the clamping force of the machine should enable handling of the pressure during the process. Inadequate clamping force results in die deformation and parts of inadequate quality.

HAICHEN is capable of providing machines with different clamping forces ranging from 30 tons to 3000 tons, which assists in the selection of appropriate machines depending on the size and intricacy of the aluminum radiator parts.

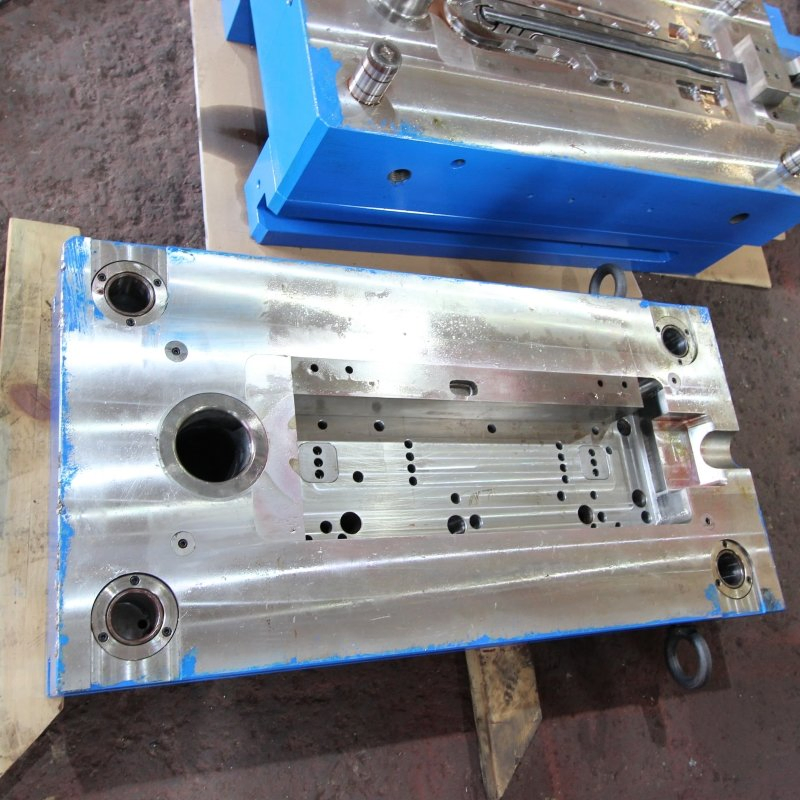

Machine selection for aluminum radiators

Shot Size

The shot size refers to the amount of molten metal that the machine can handle in one cycle. It should be In one cycle, a machine is capable of processing a specific volume of molten metal referred to as shot size. Shot size of the machine should correspond to the dimensions of the radiator being manufactured for efficiency and consistency.

With regards to aluminum radiators, HAICHEN has a variety of cold chamber die casting machines with specific shot sizes designed for different sizes of radiators. For instance:

- HCD300-C Die Casting Machine: Designed for small size radiators (350 mm in length).

- HCD580-C Die Casting Machine: For medium size radiators (length of 500 mm).

- HCD880-C Die Casting Machine: For bigger radiators (length up to 600 mm).

These machines are designed with the systems of advanced shot control which guarantee strick. And uniform injection of molten aluminum which is very crucial for achieving the required standard of quality and uniformity for the end product.

By selecting a machine with the appropriate shot size. Manufacturers can optimize production efficiency and ensure that each radiator meets the highest standards of quality and reliability.

Cooling System

It’s critical to implement a robust system designed to rapidly cool molten aluminum after casting. So that the parts solidify uniformly, maintaining their shape.

Contemporary die casting machinery possesses sophisticated cooling systems with individually controllable, multi-circuit cooling systems. Each coolant circuit can be managed independently with temperature set points for control during the cooling period of the casting cycle.

Such accuracy guarantees no shrinkage or warping, as would be the case, ensuring all components of the radiators are produced with high accuracy in terms of dimensions, features and surface finish.

Automation

Production efficiency can dramatically be improved and labor costs lowered with the use of automated machines.

Purchasing machines that include automation for material handling and part removal would increase precision and reliability of the devices.

A steady supply of molten aluminum can be assure with automated material handling systems. And finished components can be remove from the mold using robotic arms or ejector systems.

Reduction in manual work boosts the overall standard the product attains. And coupled with the reduction in a host of defects that may occur, offers far greater quality.

Furthermore, automated machines would enable continuous operation, yielding greater uptime as well as activity level, thus increasing volume of output produced.

Energy Efficiency

Overall costs that the business incurs during production will be greatly reduced by choosing machines optimally designed for energy efficiency. As expenditure of operations in terms of maintenance and resources will be minimized.

HAICHEN Application Example: Efficient Production Solution for New Energy Vehicle Aluminum Cooling Plates

HAICHEN provided a customized die-casting solution for a customer’s production line of aluminum cooling plates for new energy vehicle battery packs, successfully addressing the challenges of manufacturing large, thin-wall components.

- Project Background & Core Challenges

- HAICHEN’s Targeted Solution

- Results Achieved

Project Background & Core Challenges:

The product was a large, complex cooling plate with overall dimensions of approximately 600mm*400mm and internal channel walls as thin as 2mm.

Requirements included extremely high sealing, flatness, and a fast production cycle to meet batch delivery schedules.

HAICHEN’s Targeted Solution:

- Equipment Selection: Recommended an HAICHEN 880-ton cold chamber die casting machine to ensure sufficient clamping force and mold space.

- Process Configuration: Equipped with a high-speed injection system and a large-capacity closed-loop mold temperature controller to optimize filling and temperature management.

- Process Optimization: Optimized the gating and venting system through simulation analysis and applied vacuum assistance to ensure perfect filling and internal density of the ultra-thin channels.

Results Achieved:

- Quality Improvement: The first-pass yield of the product increased to 98.2%.

- Efficiency Gain: The production cycle time was reduced to 75 seconds.

- Cost Optimization: The stable, low energy consumption of the equipment significantly reduced the cost per part.

- Capacity Assurance: The solution fully met the customer’s demand for high-volume, stable delivery.

Manufacturer of Aluminum Radiator Cold Chamber Die Casting Machines

HAICHEN specializes in the manufacturing of cold chamber die casting machines. Specifically focusing on processes related to the production of aluminum radiators.

Cutting-edge controls, cooling, and automated part handling guarantee consistent quality and high production efficiency.

As leaders in the die casting industry over the last 20 years. HAICHEN is most capable in meeting your aluminum radiator production needs, delivering dependable solutions and advanced technology.

For machine selection for aluminum radiators, a range of criteria are consider. Such as machine tonnage, precision and control systems, cooling, energy, alloy compatibility, and automation.

Streamlined production processes, high quality standards, and operational efficiency are achieve by considering all factors.