The most effective alloys for die casting include aluminum, zinc, magnesium, copper, tin, and lead alloys, each offering unique properties for specific applications.

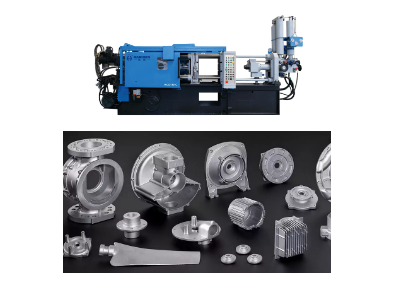

Die casting is a metal casting method that forces molten metal into a mold with high pressure.

The machine was utilized to manufacture metal components extremely accurately and repeatedly. Hence, the choice of alloy is very important for obtaining the desired properties in the product.

In this article, we’ll examine some of the best alloys for die casting and discuss the applications.

The choice of metal is of great importance for the quality and mechanical properties of the die cast component. For this reason, here we have a list of the best “web” to be used in die casting.

Aluminum Alloys

One of the most commonly used materials in engineering applications is aluminium alloy because of its good strength to weight ratio, particularly when the operation of the product involves moving parts; but also due to its low weight, resistance to corrosion, and good conductivity. Accordingly, its use in automotive and aerospace industry is popular for those features.

- Aluminum Alloys

- Real-world application example

- Haichen Die Casting Machine Recommendation

Aluminum Alloys

These alloys are used extensively in the automotive, aerospace and electronics industries for components that require both strength and minimal weight.

- 300 Series (Al-Si): These alloys are renowned for their excellent fluidity, rendering them well-suited for intricate shapes. They offer excellent castability and good mechanical properties.

- The 400 Series is an aluminium-silicon-copper alloy. These alloys boast higher strength and hardness compared to 300 series alloys, though they are less ductile. These products are frequently employed in applications that demand higher strength.

Real-world application example

The automotive ECU housing is die-cast using A380 aluminum alloy (an aluminum-silicon-copper alloy). The mold can achieve a die-casting life of up to 100,000 cycles at an operating temperature of 680°C.

Haichen Die Casting Machine Recommendation

HAICHEN’s cold chamber die casting machines are specifically designed to handle aluminum alloys with high melting points. These machines feature:

- High injection pressure and speed control

- Real-time shot monitoring

- Energy-efficient hydraulic systems

- Ideal for automotive parts, LED housings, and electronic enclosures

Zinc Alloys

Good castability is a feature of all zinc alloys, including thin walls and extended sections containing bends.

Due to their increased strength these alloys are often used by industries in the manufacture of small fasteners, automotive components and toys.

- ZA-8 (Zn-4Al): Known for its high strength and castability. This is a common process of small and complicated parts.

- ZA-12 (Zn-3Al-0. 5Mg): This alloy achieves a balance between strength, ductility and castability. It is ideal for components that demand a blend of these characteristics.

HAICHEN hot chamber machines are optimized for zinc and other low-melting-point alloys. They offer:

- Faster cycle times

- Lower energy consumption

- Precision casting for small, intricate parts

- Commonly used for lock parts, zipper sliders, and decorative hardware

Magnesium Alloys

Magnesium alloys: Being the lightest of the die casting alloys, magnesium alloys’ use provides immense savings in weight in applications where weight is a critical grind. These materials are use regularly in aerospace applications or vehicles requiring dramatic weight reductions. They include:

- AZ91D (Mg-Al-Zn): Known for the outstanding strength-to-weight ratio. The most common material is also use in the automotive industry due to the limited ability to reduce weight.

HAICHEN also provides specialized magnesium die casting machines with:

- Vacuum-assisted injection systems

- Anti-oxidation protection

- Suitable for lightweight automotive and aerospace components

HAICHEN’s Practice in Alloy-Process Co-Optimization

HAICHEN’s value lies not only in providing die casting machines for different alloys but also in offering deep process support to help customers fully realize each alloy’s potential.

Based on our understanding of different alloy properties (like aluminum’s flow, magnesium’s lightness, zinc’s surface finish), we provide targeted optimization in mold design, injection profiles, and temperature control strategies.

For example, when developing a large thin-wall magnesium automotive part for a customer, our team solved challenges with filling and warpage by optimizing vacuum assistance and mold temperature gradients.

This allowed the product to meet its weight reduction goal while achieving a stable yield rate over 99% and increasing production efficiency by more than 25%.

Copper Alloys

Materials such as copper alloys (brass, bronze) provide good thermal and electrical conductivity, suitable for applications such as heat dissipation or electrical contact. They are also include in ornamental products because of their ornamental value.

- Copper based alloys (brass and bronze) exhibit high thermal/electrical transit properties. And then these characteristics are often use in demanding applications.

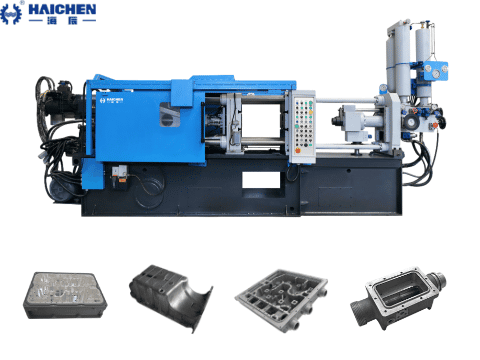

Die Casting Machine Manufacturer: Efficient Alloy Processing

The above is the introduction of the HAICHEN die casting machine factory, which specializes in the production of high-quality die casting equipment and die casting technical solutions.

Our die cast machines feature top of the line hay and sleeve presses for same quality every time. Therefore, the product is widely applied in the automotive, aerospace, electronics, and other industries to address a broad range features in complex die casting.

We are committe to providing our customers with efficient and energy-saving die-casting solutions. Our objective is to assist clients in optimising their production efficiency and enhancing the quality of their products.

The choice of the best alloy to cast is dependent on the nature of the application such as strength, weight, heat transfer characteristics, corrosion resistance, casting properties and cost.

Aluminium, zinc, magnesium and copper alloys possess material properties that make them appealing to different markets and applications. Hence the selection of the proper alloy to achieve the best performance and efficiency in a multitude of uses cannot be overemphasized.

Finally, through these right alloy choice and advanced die casting machines, manufacturers can produce high-quality, durable, and precise components.