A die casting machine heating bush is a component of a die casting machine used to heat the mould or mould cavity.During the die casting process, the mould needs to be kept at a certain temperature to prevent thermal shock and casting defects caused by temperature differences.

The heater bush usually maintains the temperature of the die by providing heat through an internal heating element such as a resistance heater or a high-frequency induction heating coil.

The control of mould temperature is particularly important in high pressure die casting because the temperature of the mould surface directly affects the quality of the casting.

For example, in aluminium high-pressure die casting, the die surface temperature usually needs to reach 300°C to ensure that the casting is evenly filled and to reduce porosity.

In addition, the design and choice of material for the heating bush is critical to ensure that it can withstand the cyclic and mechanical stresses of the mould at high temperatures.

Heating bushs are not only used to maintain mould temperature, but also to reduce energy consumption and increase productivity by optimising heat flow distribution.

The heating bush is therefore a key component in a die casting machine and is essential to ensure the production of high quality castings.

The role of die-casting machine heating bush

The role of die casting machine heating bush is mainly to ensure that the molten metal temperature stability in the die casting process.

Thus improve product quality and production efficiency.

Specifically, the main functions of the heating bush include:

- Maintain the temperature of the molten metal

- Improve production efficiency

- Improve product quality

- Extend the life of the mould

- Optimise process control

Maintain the temperature of the molten metal

The heating bush heats up the injection tube or material pot and other parts through heating elements (such as electric heaters).

Ensure that the molten metal is at the right temperature before entering the mould.

Avoiding low temperatures that could lead to reduced fluidity or defects.

Increase productivity

By maintaining the temperature of the molten metal, production interruptions due to temperature fluctuations are reduced.

This improves productivity.

Improve product quality

Stable temperature can reduce the thermal shock of the molten metal when filling the mould.

Reduce the rate of casting defects, such as porosity, shrinkage holes, etc..

It also helps to improve the surface quality of the castings and the uniformity of the internal structure.

Extend the life of the mould

The heating bush helps to reduce the thermal fatigue stress of the mould.

Avoid cracking or deformation of the mould caused by sudden temperature changes, thus prolonging the service life of the mould.

Optimise process control

The heating bush is using in conjunction with other control systems of the die casting machine (such as cooling system).

Can better control the temperature of the mould and molten metal.

Achieve more accurate process control, improve the consistency and reliability of production.

Die casting machine heating bush plays a vital role in the die casting process.

It not only directly affects the quality of castings and production efficiency, but also has an important impact on the life of the mould and the stability of the equipment.

How to use die-casting machine heating bush?

Die casting machine heating bush is with die casting machine injection parts and die casting products mould to use together!

The main method involves the following aspects:

- The role of the heating bush

- Heating bush heating method

- Use steps

- Precautions

- Maintenance

The role of heating bush

The heating bush is used to heat the material pipe, injection nozzle and other parts of the die casting machine, in order to improve the production efficiency and product quality.

Through the heating bush, can ensure that the liquid metal before entering the mould to reach the appropriate temperature.

So as to reduce the casting defects, such as deformation, hot pressure, surface depression.

Heating mode of heating bush

Our Haichen heating bush usually adopts electric heating or thermal oil heating.

Electric heating is simple but slow to heat up.

While thermal oil heating can provide more uniform temperature control, suitable for the need for high-precision temperature control occasions.

Use steps

Preheat

Before formal die casting, should be preheating the mould and heating bush, in order to reduce the temperature gradient at the beginning of production, to avoid mould damage due to sudden cold or heat.

The preheating temperature is generally between 150°C and 350°C, depending on the type of alloy used.

Temperature control

The heating bush should be used in conjunction with the mould thermostat to maintain the temperature of the mould and the feed tube within the set range (usually between 180°C and 260°C) by means of an automatic control system.

This will ensure casting dimensional stability and improve product quality.

Exhaust operation

After the first operation, long shutdown or mould change, exhaust operation is required to improve the heat conduction effect.

The specific method is to set the temperature to zero degree and run for 10 minutes; increase the temperature to 120℃ and run for 20 minutes to exhaust; then adjust to the normal production temperature range.

Precautions

The installation position of the Haichen heating bush should ensure good thermal contact to avoid local overheating or cold spots.

The operating status of the heating bush should be checked regularly during use to ensure that it works properly and to avoid interruption of production due to failure.

In the heating process, should avoid long time direct high temperature baking on the mould or material tube, so as not to cause material damage.

Maintenance

Regular maintenance of the heating bush, clean up the scale and corrosion, to ensure its long-term stable operation.

Through the reasonable use of die-casting heating bush, can significantly improve the efficiency of die-casting production and product quality, at the same time to extend the service life of the mould.

Haichen high quality die casting machine

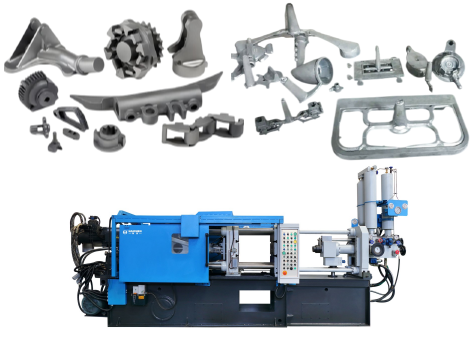

Haichen is a professional die casting machine manufacturer with more than 20 years of production experience.

Its products cover both cold chamber and hot chamber die casting machines for a wide range of non-ferrous metals such as aluminium, zinc and lead.

Haichen offers a wide range of tonnages of cold chamber and hot chamber die casting machines. Cold chamber die casting machines are suitable for low melting point alloys such as aluminium, zinc and copper.

And hot chamber die casting machine is suitable for zinc, lead and other high melting point alloys.

Among them, the C series cold chamber die casting machine is suitable for the production of medium-sized die castings, which are widely using in automotive, home appliances, 3C electronic products, aerospace and other industries.

Hot chamber die casting machines are available in tonnage ranges from 15 tonnes to 280 tonnes and are mainly using in casting low melting point metals such as zinc and lead alloys.

Haichen’s die casting machines are environmentally friendly, energy efficient, automated and intelligent, and can meet customers’ long-term usage needs.

Our products are exporting to more than 30 countries or regions.

The company provides online support and engineer support to ensure that customers’ needs are met in a timely manner.

With its advanced technology and rich experience, Haichen has high competitiveness in the die-casting machine market.

Its products are not only stable in performance, but also reasonably priced, which can increase users’ productivity and reduce costs.

Haichen’s die casting machines have become one of the most important brands in the die casting industry due to their high quality, high performance and wide range of applications.

Whether it is cold chamber or hot chamber die casting machine, Haichen can provide solutions to meet different customer needs.