The electrical system maintenance of a die casting machine is a crucial component that controls and monitors various aspects of the machine’s operation.

Given the high failure rate of molds and equipment in the die casting industry, companies must prioritize preventive maintenance to avoid production disruptions caused by equipment failures.

Consequently, by developing a comprehensive preventive maintenance program, they can enhance equipment reliability and minimize unplanned downtime.

What is Electrical Maintenance?

Electrical maintenance is the process of ensuring that electrical equipment is kept in good working order.

It includes inspecting, testing, and repairing electrical equipment as necessary to prevent problems that could lead to a loss of power or an electrical fire.

The Importance of Electrical Maintenance

Electrical maintenance is of vital importance for die-casting machines.This helps manufacturers avoid costly equipment repairs or replacements.

Regular maintenance helps detect and resolve issues before they escalate into high maintenance costs, reduces energy consumption, ensures compliance with safety regulations, and ultimately guarantees the normal operation of the manufacturer.

The electrical maintenance work of die-casting machines is usually carried out by electricians and maintenance personnel who are familiar with the maintenance procedures.

For example, engineers at Haichen usually follow or use an electrical equipment maintenance checklist.

To ensure the safety of the working environment during maintenance, personnel in the work area must always abide by electrical safety regulations.

Electrical system maintenance of a die casting machine

Regular maintenance of the electrical system is essential to ensure its reliable operation and prevent costly downtime.

Inspection and maintenance of the electrical control system:

- The electrical control system is the core part of the die casting machine and is responsible for controlling the execution of the machine’s actions.

- Therefore, it is very important to regularly check the components of the electrical control system, including the motor, PLC (Programmable Logic Controller), relays and switches.

Power management:

- Ensure that the power supply is stable and meets the requirements of the machine.

- If you do not use the machine for an extended period of time, then turn off the power to avoid unnecessary energy consumption and potential electrical failures.

Maintenance of circuit boards and sensors:

- Since circuit boards are a crucial component of the electrical system, technicians must inspect them regularly for damage or deterioration.

- Sensors such as temperature sensors and pressure sensors also require regular calibration and maintenance to ensure their accuracy and reliability.

Preventive Maintenance Strategies:

- The reliability and longevity of equipment can be significantly improved by employing preventive maintenance strategies.

- For example, regularly clean and lubricate electrical connection points, and inspect and replace deteriorated cables and connectors to prevent electrical shorts or failures.

Troubleshooting and Repair:

- Troubleshooting should be done in a timely manner when abnormalities in the electrical system are detected.

- Common problems include power fluctuation, motor overheating, and sensor failure. These problems need to be dealt with promptly by professional maintenance personnel to avoid further equipment damage.

The impact of environmental factors:

- Die-casting workshop is usually harsh environment, there are high temperature, high humidity and corrosive gas conditions, these will have an impact on the electrical system.

- Therefore, regular inspection of the electrical system of waterproof, dustproof measures, and take the necessary protective measures is very necessary.

What are the common types of electrical faults in die-casting electrical systems?

- Power failure

- Sensor failure

- Control panel failure

- PLC Controller Failure

- Electrical components damaged

- Circuit faults:

- Winding fault:

Power failure

The press machine fails to start or frequently trips. This could be caused by unstable power voltage, short circuits or open circuits in the power lines, overload or short circuits, etc.

The repair methods include checking the power voltage, lines and internal components to ensure stable power supply.

Sensor failure

The sensor is not functioning properly, causing the die-casting machine to be unable to control accurately.

Common causes include problems with the sensor’s power supply or wiring, contamination or impurities, or damage to the sensor.

Repair methods include checking the power supply, cleaning the sensor, or replacing the damaged sensor.

Control panel failure

The control panel is not functioning properly, causing the die-casting machine to fail to start or operate abnormally.

Possible causes include power or wiring issues, component damage or failure.

Repair methods include checking the power supply, wiring, and components, and replacing or repairing the control panel if necessary.

PLC Controller Failure

The PLC (Programmable Logic Controller) is the core control component of the electrical system of the die-casting machine.

Its failure may cause abnormal automated operations.

Common failures include abnormal input and output signals, damage to relays, transistors, or thermal relays, etc.

Electrical components damaged

If electrical components such as contactors, relays, and switches are damaged, it may cause abnormal startup or operation of the die-casting machine.

The repair methods include inspection and replacement of the damaged components.

Circuit faults

These include short circuits and open circuits, which may cause partial malfunction or abnormal operation of the die-casting machine.

The repair methods include inspecting the circuits, repairing or replacing the damaged circuits.

Insurance burnout, loose wiring connectors, electromagnetic valves, potentiometers, and sensors failure.

These faults may cause damage to the control circuit board and affect the normal operation of the die-casting machine.

The repair methods include inspection, tightening, replacement, or adjustment of the relevant components.

Winding fault

Such as inter-turn short circuit, broken wire in the winding, etc., may be caused by natural damage, poor heat dissipation or overload. Regular inspection and maintenance are required.

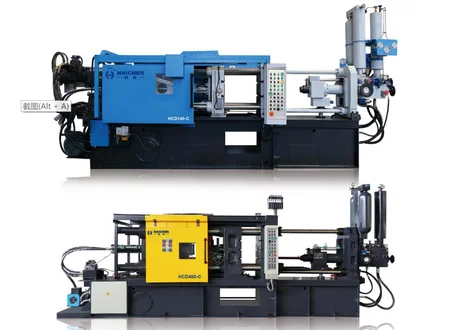

Haichen Electrical System of die casting machine

The electrical system of Haichen die casting machines is designed to provide high levels of automation, precision, and reliability.

The use of an embedded soft PLC control system enables real-time control of the die-casting machine’s ejection process, improving the response speed and ensuring the quality of the production.

Haichen is a die casting machine supplier, we mainly supply cold chamber and hot chamber die casting machine.

If there is any demand for die casting machine and electrical system of die casting machine, welcome to consult us.