Advantages of die casting products include high precision and dimensional stability, complex shape manufacturing capability and so on.

The core advantages of die casting products lie in high efficiency, high precision, excellent material properties and design flexibility. Making it irreplaceable in large-scale production. And it is particularly suitable for areas with high requirements for strength, lightweight and details.

Die casting products offer many significant advantages that make it a widely adopted process in modern manufacturing. It has many different types, like aluminium alloy die-casting mold and zinc alloy die-casting mold.They are very popular.

The following are the main advantages of die casting products:

High Precision and Dimensional Stability

Die casting is able to produce parts with excellent dimensional accuracy and stability.

Due to the high-precision design of the mold, die castings can be manufactured within very small tolerances, usually up to ±0.001 inches or less. This high precision allows die castings to be used directly in many applications without further processing.

High Output and High Efficiency

The die-casting process is highly automated, enabling the rapid production of thousands of identical parts at rates far exceeding those of other manufacturing methods, making it suitable for large-scale mass production. Hourly output can reach hundreds of parts, significantly reducing lead times.

For example, Haichen produce aluminium cookware handle with 12 pieces in one mold. With experienced die casting technology, this high output die casting products with good quality.

Reusable moulds

Die casting molds are reusable, spreading initial mold costs over long-term production, while unit costs decrease as production increases.

Save on material and processing costs

- Near-net-shape production reduces or even eliminates secondary operations (such as cutting), reducing material waste and subsequent processing costs.

- Compared to plastic injection molding, rising oil prices have led to rising plastic raw material costs. Die-casting metals (such as aluminum and zinc) offer superior long-term economics.

Complex Shape Manufacturing Capability

The die casting process can easily manufacture complex geometries and internal structures that are often difficult to achieve with other manufacturing methods.

For example, die casting can produce parts with thin walls, complex cavities, and porous structures. This capability makes die casting very popular in the automotive, electronics, and consumer goods industries.

Like Haichen aluminum radiator mold, with skilled design engineers. Haichen can produce different specification aluminium radiator with or without core mold. Thus to meet customer’s requirements according to production cost.

Achieving High-Precision Complex Geometries

The die casting process is capable of producing parts with tight dimensional tolerances and complex geometries. Including thin-walled structures, fine details, internal cavities, and three-dimensional forms. High-pressure filling allows the molten metal to precisely replicate every detail of the mold, enabling the creation of complex designs that are difficult to achieve with other processes.

Thin-Wall and Structural Integration Capabilities

Die casting can produce complex parts with extremely thin walls (typically over 0.5mm) and achieve multi-component functional integration. Replacing traditional assembly parts with a single casting reduces assembly steps and production costs, while also improving structural consistency and reliability.

Reduced Post-Processing Needs

Die castings offer excellent dimensional stability and surface finish, often eliminating the need for secondary machining to meet required tolerances (±0.001 inch). This significantly reduces production cycle time and machining costs.

High Design Freedom

The process supports complex curved surfaces, hollow structures, and fine textures, breaking through the limitations of traditional manufacturing.

High strength and durability

Die castings generally have high mechanical properties, including strength, rigidity and corrosion resistance.

This is because the metal is cooled rapidly under high pressure during the die casting process, forming a fine grain structure, which improves the mechanical properties of the material.

Material Properties Provide Superior Strength

Die casting utilizes high-strength metal materials such as aluminum alloys, magnesium alloys, and zinc alloys. These alloys are crystallized under high pressure, resulting in a fine, uniform grain structure that significantly enhances the product’s hardness and strength.

Corrosion Resistance

Die-cast alloys (such as aluminum and zinc) are naturally highly corrosion-resistant and maintain stable performance in harsh environments (such as high temperature and humidity).

Temperature Resistance

Die-cast parts can withstand extreme temperatures (-40°C to over 200°C), surpassing most plastic parts (which are prone to deformation or melting).

Fatigue and Wear Resistance

The high-pressure forming process creates a dense and uniform microstructure, reducing internal defects (such as pores), thereby improving wear, impact, and fatigue resistance.

Excellent surface quality

Die castings usually have a smooth surface, reducing the need for subsequent processing.

This surface quality is not only aesthetically pleasing, but also helps improve the functionality of the part, such as reducing friction and wear.

Surface Smoothness and Finish

The die-casting process can directly produce highly smooth surfaces. Most evidence indicates that surface roughness can reach Ra 5-8 (equivalent to ISO N5-N8). Some high-precision die-cast parts can even achieve Ra 4.

Reduced Post-Processing Steps

- Die-cast parts typically require no secondary processing to meet service requirements, significantly reducing subsequent polishing and grinding costs.

- Aluminum die-cast parts offer a smooth, ready-to-use surface immediately after demolding, making them particularly suitable for consumer electronics and automotive exterior parts.

- Zinc die-cast parts can be directly electroplated or painted, requiring fewer surface pre-treatment steps.

Dimensional Accuracy and Surface Consistency

- High dimensional accuracy (tolerance grades IT6-IT7) and excellent surface finish complement each other.

- Precision mold machining and high-pressure forming ensure consistent surface quality across thousands of parts, meeting stringent interchangeability requirements.

High production efficiency

Die casting is a high-speed production process suitable for large-scale production.

By using high pressure and quickly filling the mold, die casting can produce a large number of parts in a short period of time, thereby reducing the cost per unit product.

High-Speed Production Capabilities

The die casting process is capable of extremely high production rates. Evidence suggests that die casting machines can produce hundreds of parts per hour, with annual output reaching millions of parts.

Fast Production Cycle

From metal injection to part formation, die casting boasts extremely short cycle times. Combined with automated systems, this allows for uninterrupted, continuous production, significantly increasing output per unit time.

Cost Advantages of Scale

Although the initial mold cost is relatively high, high-speed production significantly reduces the cost per part when mass-producing.

Environmental protection and sustainability

Die casting materials such as aluminum, zinc and magnesium have good recyclability, which makes die casting products have advantages in environmental protection.

In addition, the die casting process can reduce material waste and improve material utilization.

High material utilization and minimal waste

The die-casting process significantly reduces waste by controlling material flow through precision molds. Waste materials (such as gates and overflow trough metal) are 100% recyclable, creating a closed-loop system.

Energy Efficiency and Low Carbon Emissions

- Die casting offers a short production cycle and high efficiency, with unit energy consumption lower than other processes such as injection molding and sand casting.

- The advantages of lightweighting (such as automotive aluminum die castings) reduce energy consumption in end products, indirectly reducing greenhouse gas emissions.

Material Sustainability

Common die-casting materials (aluminum, magnesium, and zinc alloys) are infinitely recyclable, requiring only 5% of the energy required for ore mining, significantly reducing resource consumption.

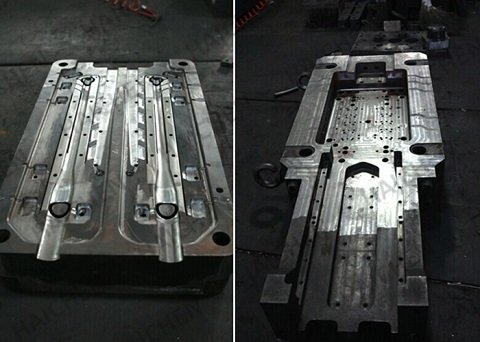

Haichen die casting mold

Haichen die casting mold possesses a complete technical system. From structural simulation, material selection to mold processing, assembly and debugging. Haichen’s mold solutions have widely covered multiple fields such as automotive, electronics, and industry. For example, aluminium alloy pancake pan mould, cast aluminum cookware, aluminum radiator mold and so on. It can provide customized mold design and production services according to the specific needs of different industries.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine.They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

When you have any demand, feel free to contact us.