Die casting in manufacturing is a precision casting method in which molten metal is injected into a precision-designed mold under high pressure to form a part of the desired shape.

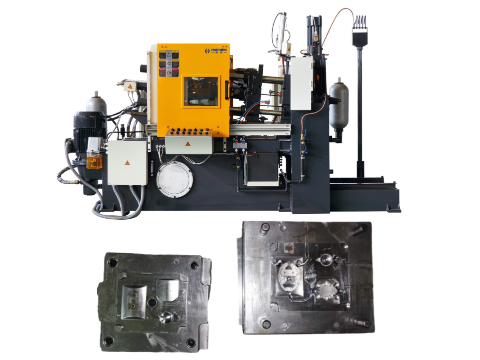

Afterward,die-casting molds are typically made of tungsten carbide tool steel that is carefully machined to preset shapes.

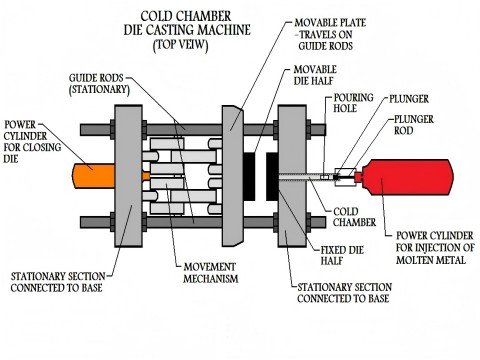

Basically ,the die casting process includes preparation, clamping, injection, and cooling steps.

To produce highly accurate, dimensionally stable, and well-surfaced parts.

Main features of die casting in manufacturing

- High precision and dimensional stability

- High strength and hardness

- Suitable for complex shapes

- High-speed production

- Variety of material options

- Cost-effective

- Surface treatment

High precision and dimensional stability

The dimensional accuracy of die casting parts is usually 6-7 grades, or even up to 4 grades.

The surface quality is good, and the surface roughness is Ra 1-2.5 microns.

High strength and hardness

The strength and hardness of die castings are usually 25-30% higher than those of sand castings, but the productivity is lower.

Suitable for complex shapes

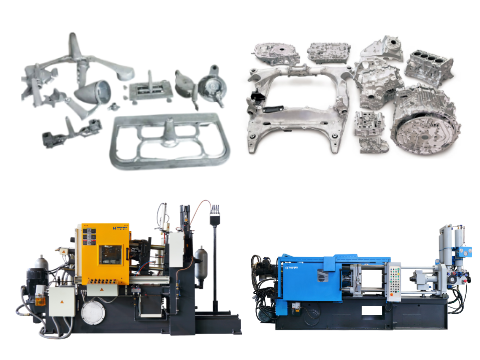

Die casting can produce parts with complex shapes, such as thin-walled structures and fine features.

And is suitable for automotive, aerospace, electronics, home appliances and other industries.

High-speed production

The die-casting process is fast and can complete multiple cycles per minute, making it suitable for large-scale production.

Variety of material options

Commonly used die-casting alloys include zinc, aluminum, magnesium, copper, lead, tin, etc., and different alloys are suitable for different application scenarios.

Cost-effective

Despite the higher cost of tooling, the cost of a single part is relatively low, making it suitable for high-volume production.

Surface treatment

The surface of the die casting is smooth, and the surface treatment such as painting and electroplating can be carried out to improve the corrosion resistance and aesthetics.

Die casting process in manufacturing

- Mold preparation

- Filling

- Cooling and curing

- Demoulding

Mold preparation

The mold is made of cemented carbide tool steel, which is divided into fixed half die and movable half die.

Filling

Molten metal is injected into the mold cavity through the gate.

Cooling and curing

The metal is cooled and cured into shape under high pressure.

Demoulding

After cooling, the mold is opened and the casting is taken out.

Applications

Automotive: engine parts, transmission housings, wheels, etc.

Aerospace: Lightweight, high-strength components.

Electronics: heat sinks, connector housings, etc.

Home appliances: washing machines, refrigerators and other components.

Toys: model cars, toy parts, etc.

The main advantages of the die casting process

- High production efficiency

- High precision and surface quality

- Cost-effective

- High material utilization

- Strength and durability

- Environmentally friendly

- Automation and mechanization

- Multiple surface treatment options

High production efficiency

Die casting is a continuous production process that can produce a large number of parts in one go, hundreds to thousands of parts per hour, significantly improving production efficiency.

High precision and surface quality

Die castings have high dimensional accuracy and good surface finish. Moreover, the minimum wall thickness can reach 0.3mm, making them suitable for manufacturing complex-shaped and precision parts.

Cost-effective

The die casting process can reduce labor and equipment investment, and reduce production costs.

For example, the integrated die casting technology reduces the number of parts.

And the number of solder joints is reduced from 700-800 to about 50, which greatly reduces costs.

In addition, the short production cycle of die castings and the long life of the molds further reduce the production costs.

High material utilization

Due to the recyclability of metal, the die casting process can make efficient use of materials and reduce waste.

Strength and durability

Die castings have high strength and hardness, which makes them suitable for producing thin-walled complex parts, and additionally, they offer good heat and UV resistance.

Environmentally friendly

Aluminum alloy die casting technology does not need to add a large amount of grease and other toxic and harmful substances.

Accordingly, we can reduce environmental pollution and energy consumption by controlling process parameters and optimizing waste recycling.

Automation and mechanization

The die-casting process is easy to realize mechanization and automation.

Then,which reduces the error and labor intensity of human operation, and improves production consistency and product quality.

Multiple surface treatment options

Die castings have a smooth surface and can be used directly or can be finished.

Such as plating or painting, adding to the aesthetics and functionality of the product.

Get Started with Die Casting

Die casting is a versatile and efficient manufacturing process that offers significant advantages for producing high-quality, high-volume metal parts.

Whether you’re working in the automotive, aerospace, or consumer electronics industry, die casting provides the precision, strength, and cost-effectiveness needed to bring your designs to life.

If you’re ready to start your next die casting project, Haichen is here to help.

Our platform offers instant access to a vetted supply chain, fast quoting, and comprehensive support to ensure your project’s success from prototyping to full-scale production.