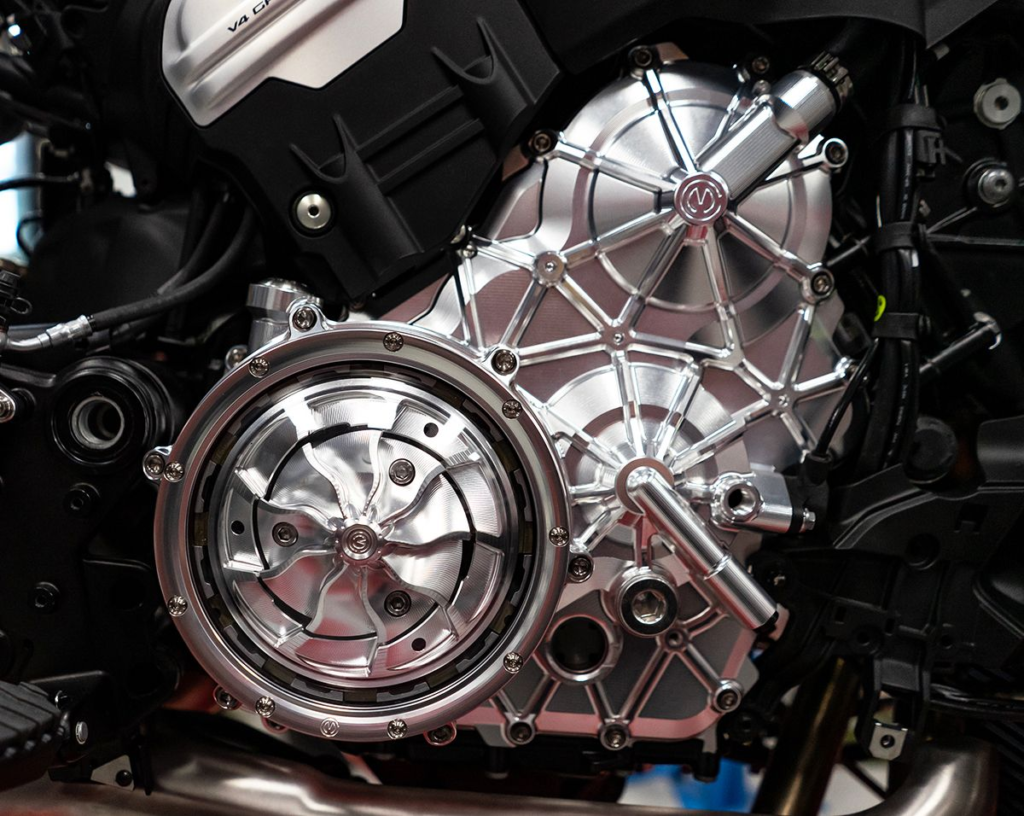

Structure and principle of crankcase:The crankcase die casting machine features a robust frame with a crank mechanism that converts rotary motion into linear motion, enabling precise control of the mold’s opening and closing, while its principle involves injecting molten metal into a closed mold cavity at high speed and pressure to form complex parts.

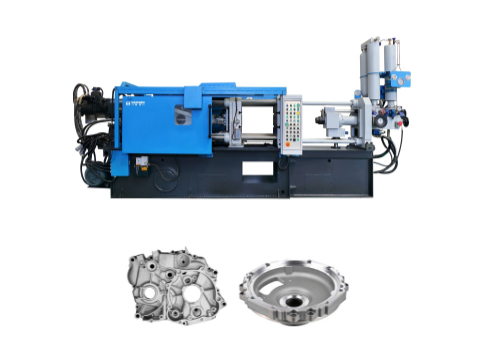

Crankcase die-casting machines are mainly used to produce precision metal parts such as engine crankcases.

This type of equipment uses die-casting technology (i.e., the technology of injecting molten metal into a mold to form it), combining advanced technology with high-strength mechanical structure to ensure high-quality production of products.

This article will introduce the construction and working principle of crankcase die-casting machines in detail.

Structure of Crankcase Die Casting Machine

- Injection System

- Mold Clamping System

- Melt Handling System

- Ejection System

- Control System

Injection System

The core of the crankcase die-casting machine is the injection system. This system consists of three key components: the injection cylinder, the plunger and the nozzle.

Its function is clear: to quickly and accurately deliver molten metal into the mold cavity under high pressure. During operation, the injection cylinder drives the plunger to move and push the molten metal into the mold through the nozzle.

Mold Clamping System

In the crankcase die-casting machine, the mold clamping system plays a vital role – its task is to ensure that the two halves of the mold are always tightly closed during the injection of molten metal.

This system consists of three key components: the clamping plate that fixes the mold, the tie rod that bears the tension, and the lever mechanism responsible for providing the clamping force.

The importance of the clamping force should be emphasized here: when the hot molten metal is injected into the mold under high pressure, it will generate a huge expansion force. The clamping system must generate a strong enough clamping force to resist this expansion force and prevent the mold from being stretched open and causing metal leakage.

The clever design of the lever mechanism is that it can generate a strong clamping force with a relatively small driving force through the principle of mechanical amplification. This design not only saves energy, but also ensures stable operation of the equipment

Melt Handling System

The melting treatment system of the crankcase die casting machine is mainly used for metal melting and temperature control.

The system consists of three core parts: the melting furnace is responsible for heating the solid metal to liquid; the holding furnace maintains the stable temperature of the molten metal to ensure that it is in an injectable state; the transfer device is responsible for transporting the molten metal from the holding furnace to the mold area.

Ejection System

The ejector system is responsible for removing the casting from the mold after it is formed. This system includes ejector pins, ejector plates and drive devices. When the molten metal cools and solidifies, the ejector pin pushes the finished part out of the mold cavity, and the operator can remove the finished part, while the mold is ready for the next production cycle.

Control System

The operator manages the entire die-casting process through the human-machine interface. The system consists of three parts: sensors, PLC controllers and operation panels:

- Real-time parameter control: The operator can manually set core parameters such as injection speed, pressure and mold temperature. For example, the mold closing action will be divided into 4 levels of pressure regulation, and the mold opening will be divided into 3 levels of flow control to ensure a smooth transition of the action.

- Dynamic process monitoring: The sensor continuously collects data (such as injection curve, mold temperature), and the PLC automatically compares the preset value. If a deviation is detected (such as abnormal pressure), the system immediately triggers the adjustment program.

- Safety and efficiency coordination: The emergency stop button and safety interlock device are integrated in a conspicuous position on the operation panel, and the robot control module supports automatic pickup to reduce manual intervention.

Principle of Crankcase Die Casting Machine

- Preparation

- Injection

- Solidification

- Ejection

- Cycle Repeat

Preparation

Crankcase die-casting machine mold preparation process:

- Clean the mold thoroughly – Use special tools to remove the residue on the mold parting surface

- Spray the release agent evenly – Cover the isolation coating in the upper and lower mold cavities to ensure smooth demolding of the liquid metal

- Precise mold locking – Close the mold after aligning the positioning pins and apply a 15-25MPa clamping force with a hydraulic mechanism

Injection

The operator first transfers the molten metal from the holding furnace to the injection cylinder. Then, the hydraulically driven plunger begins to advance: in the first stage, the molten metal is pushed at a relatively slow speed to fill the front end of the injection cavity, allowing the air to be fully exhausted; in the second stage, it switches to a high-speed and high-pressure mode to accurately inject the molten metal into the mold cavity. Through this staged pressure control, the molten metal can quickly fill every detail of the cavity, and finally obtain a casting that is completely consistent with the mold design.

Solidification

During the crankcase die casting process, the molten metal begins to cool and solidify immediately after being injected into the mold. The operator needs to keep the mold closed until the casting is completely solidified. By precisely controlling the cooling parameters (such as mold temperature and pressure holding time), it is ensured that all parts of the casting solidify synchronously, thus avoiding defects such as shrinkage cavities and looseness.

Ejection

When the metal is completely solidified, the mold opens automatically. At this point, the ejection system smoothly pushes the formed crankcase out of the mold. Operators need to carefully remove the parts and carefully check the surface quality and dimensional accuracy. After confirmation, the parts will be sorted and stored, waiting for subsequent finishing or packaging processes.

Cycle Repeat

The operator needs to complete the steps of mold cleaning, spraying release agent. And closing the mold before starting a new round of production. The entire process is controlled by a highly automated system to ensure part processing efficiency and quality stability.

Crankcase die-casting process

- Mold closing and locking: After the mold is closed, high pressure mold locking is performed to prevent mold expansion.

- Metal liquid injection: Molten aluminum alloy (pouring temperature 665±15℃) is poure into the pressure chamber. And the injection punch pushes the mold filling.

- Pressure boost and pressure holding: After filling, high pressure is maintain for 10-20 seconds to promote metal shrinkage compensation.

- Cooling and mold opening: Forced cooling for 15±3 seconds, the mold is open after the casting solidifies. And the ejection mechanism ejects the crankcase.

- Post-processing: Deburring, heat treatment, and machining to improve dimensional accuracy.

Haichen: China’s famous die-casting machine manufacturer

HAICHEN is a well-known die-casting machine manufacturer in China. And has accumulated rich technical experience in the field of industrial equipment. Our crankcase die-casting machine focuses on solving practical problems encountered by customers in production. Such as realizing precise adjustment of process parameters through intelligent control systems, helping operators reduce debugging time. The equipment adopts a modular design. And maintenance personnel can quickly replace wearing parts, significantly reducing the losses caused by downtime and maintenance.

Specifically, the three core advantages of HAICHEN equipment are reflecte in:

- Intelligent control system: Equipped with an intuitive operating interface and real-time data feedback function. Engineers can flexibly adjust parameters such as pressure and temperature according to production needs to ensure the quality stability of each product.

- Energy consumption optimization design: Through variable frequency drive and heat recovery system. Our equipment can reduce energy consumption by about 15% compared with traditional models, helping enterprises control long-term operating costs.

- Automation integration: Provide a full-process automation solution from mold positioning to finished product removal. Customers can choose a manipulator or conveyor belt system according to production requirements to effectively reduce manual operation links.

As a national high-tech enterprise, HAICHEN’s service team is always ready to provide you with equipment selection suggestions and process optimization solutions.

HAICHEN’s Engineering Practice in Crankcase Die Casting

HAICHEN crankcase die casting machines achieve high stability and precision for large. Complex parts like engine blocks through structural optimization and intelligent control.

- High-Rigidity Clamping and Injection Systems

For large crankcase molds needing high injection pressure, HAICHEN uses reinforced toggle links and high-strength tie bars to minimize deformation. The injection system has a large-diameter servo cylinder, delivering strong shot force and fast response to ensure rapid filling of complex cavities. - Intelligent Process Control and Data Management

The HAICHEN control system includes special process modules for crankcase production. Operators can fine-tune multi-stage injection speed, pressure, and mold temperature. The system monitors and records key data (like injection curve, clamping force) each cycle, compares it to the standard window, and warns of deviations for stable process control.

In conclusion, crankcase die casting machines are indispensable equipment for manufacturing high-precision metal parts. With their specific mechanical structure and working method, operators can stably produce crankcases with reliable quality and accurate dimensions while maintaining high production efficiency.