Cooling system in die casting, effective cooling is critical for controlling solidification, minimizing defects, and optimizing cycle times.

In the die casting process, the cooling system is a key component to ensure product quality, production efficiency and mold life. Die casting is a process in which molten metal is injected into a mold under high pressure, allowing it to cool rapidly and solidify into shape.

An efficient cooling system not only helps improve die casting production efficiency, but also reduces energy consumption and waste emissions.

Mainstream die casting cooling methods

Here are the primary cooling methods used, along with their mechanisms, advantages, and applications:

- Water Cooling

- Oil Cooling

- Air Cooling

- Conformal Cooling

- Heat Pipe Cooling

- Spray Cooling (Mist Cooling)

- Thermoelectric Cooling

Water Cooling

Mechanism:

- Circulates water through channels drilled into the die to absorb heat.

- Typically uses a closed-loop system with chillers to maintain coolant temperature.

Pros:

- High efficiency: Rapid heat extraction reduces cycle times.

- Precision: Adjustable flow rates target specific die regions (e.g., hot spots).

- Cost-effective: Widely used due to water’s availability and thermal capacity.

Cons:

- Risk of corrosion or mineral buildup in channels.

- Requires strict temperature control to avoid thermal shock.

Applications:

- High-volume production (e.g., automotive parts like engine blocks).

Oil Cooling

Mechanism

- Uses oil (e.g., thermal oil) as a coolant in high-temperature dies.

- Operates at higher temperatures than water (200–300°C).

Pros

- Thermal stability: Suitable for dies requiring uniform high-temperature control.

- Reduced thermal stress: Minimizes cracking in dies for alloys like magnesium.

Cons

- Messy maintenance and potential fire risk.

- Lower heat transfer efficiency compared to water.

Applications

- Magnesium die casting (e.g., laptop housings).

Air Cooling

Mechanism

- Relies on ambient air or forced-air systems (fans/blowers) to cool the die.

Pros

- Simple and low-cost: No complex plumbing required.

- No corrosion risk.

Cons

- Low efficiency: Limited to small parts or low-production runs.

- Uneven cooling may cause warping.

Applications:

- Prototyping or low-volume zinc alloy parts.

Conformal Cooling

Mechanism

- Uses 3D-printed channels that follow the die’s contours for uniform heat removal.

Pros

- Uniform cooling: Reduces hot spots and defects like porosity.

- Faster cycles: Up to 30% shorter than traditional cooling.

Cons

- High upfront cost for additive manufacturing (e.g., DMLS).

- Limited to dies with complex geometries.

Applications:

- Precision components (e.g., medical devices, aerospace parts).

Heat Pipe Cooling

Mechanism:

- Passive devices that transfer heat via phase change (liquid-vapor) in sealed tubes.

Pros:

- No external power required: Self-regulating and maintenance-free.

- Targeted cooling: Ideal for hard-to-reach die areas.

Cons:

- Limited heat capacity for large dies.

- Higher initial cost.

Applications:

- Localized cooling in electronics housings or thin-wall castings.

Spray Cooling (Mist Cooling)

Mechanism:

- Sprays a fine mist of water or coolant onto the die surface.

Pros:

- Rapid cooling: Effective for thick sections.

- Flexibility: Adjustable spray patterns.

Cons:

- Risk of thermal shock if overused.

- Requires drainage systems.

Applications:

- Large dies for aluminum wheels or structural components.

Thermoelectric Cooling

Mechanism:

- Uses Peltier modules to create active cooling via electric current.

Pros:

- Precise temperature control: Adjustable cooling rates.

- Compact design: Suitable for small dies.

Cons:

- High energy consumption.

- Limited to low-heat-load applications.

Applications:

- Niche uses in high-precision tooling or R&D.

Comparison Table

| Method | Cooling Speed | Cost | Maintenance | Best For |

|---|---|---|---|---|

| Water Cooling | High | Low | Moderate | High-volume production |

| Oil Cooling | Moderate | Medium | High | High-temperature alloys (e.g., Mg) |

| Air Cooling | Low | Very Low | Low | Prototypes/small parts |

| Conformal | Very High | High | Low | Complex geometries |

| Heat Pipes | Moderate | Medium | Low | Localized hot spots |

| Spray Cooling | High | Medium | Moderate | Thick-section castings |

| Thermoelectric | Low | High | High | Precision R&D applications |

Key Considerations

- Material Compatibility:

- Aluminum alloys often use water cooling, while magnesium may require oil.

- Cycle Time:

- Faster cooling reduces cycle time but risks thermal stress.

- Sustainability:

- Closed-loop water systems minimize waste.

By selecting the appropriate cooling method, manufacturers enhance part quality, extend die life, and boost productivity.

What is the cooling system in die casting?

The cooling system in die casting is a critical component designed to manage heat during the casting process, ensuring proper solidification of molten metal, minimizing defects, and optimizing production efficiency. Here’s a comprehensive breakdown:

- Purpose of the Cooling System

- Key Components

- Types of Cooling Methods

- Design Considerations

- Importance of Effective Cooling

- Innovations & Challenges

Purpose of the Cooling System

- Control Solidification: Regulates how quickly molten metal cools to avoid defects like porosity, shrinkage, or warping.

- Cycle Time Reduction: Faster cooling shortens cycle times, boosting productivity.

- Die Life Extension: Prevents overheating, reducing thermal stress and die wear.

Key Components

A typical cooling system includes:

- Cooling Channels: Drilled or 3D-printed passages within the die to circulate coolant (water, oil, etc.).

- Heat Exchangers/Chillers: Maintain coolant temperature (e.g., water chillers at 10–30°C).

- Pumps and Valves: Control coolant flow rate and pressure.

- Temperature Sensors: Monitor die temperature in real time for adjustments.

Types of Cooling Methods

Water Cooling

- Mechanism: Circulates water through channels in the die.

- Use Case: High-volume production (e.g., automotive parts).

- Advantages: Cost-effective, high heat transfer efficiency.

Oil Cooling

- Mechanism: Uses thermal oil for high-temperature dies (200–300°C).

- Use Case: Magnesium alloys (e.g., electronics housings).

- Advantages: Stable at high temps, reduces die cracking.

Air Cooling

- Mechanism: Relies on fans or ambient air.

- Use Case: Prototyping or low-volume zinc parts.

- Advantages: Simple setup, no corrosion risk.

Conformal Cooling

- Mechanism: 3D-printed channels that follow the die’s contours.

- Use Case: Complex geometries (e.g., medical devices).

- Advantages: Uniform cooling, 20–30% faster cycles.

Spray/Mist Cooling

- Mechanism: Sprays coolant directly onto die surfaces.

- Use Case: Thick-section castings (e.g., aluminum wheels).

- Advantages: Rapid cooling for heavy parts.

Design Considerations

- Die Material: Steel dies require more aggressive cooling than copper alloys.

- Casting Alloy: Aluminum (high thermal conductivity) vs. magnesium (needs slower cooling).

- Production Volume: High-volume systems prioritize speed (water cooling), while low-volume may use air.

- Channel Placement: Strategically positioned to target “hot spots” (e.g., near thick sections).

Importance of Effective Cooling

- Quality Control: Prevents defects like porosity, cracks, or dimensional inaccuracies.

- Cost Efficiency: Shorter cycle times = higher output; longer die life = lower maintenance costs.

- Sustainability: Closed-loop water systems reduce waste; conformal cooling minimizes energy use.

Innovations & Challenges

- Additive Manufacturing: Enables complex conformal cooling channels impossible with traditional drilling.

- Smart Systems: IoT sensors and AI adjust cooling rates dynamically for optimal results.

- Challenges: Balancing cooling speed with thermal shock risk; maintaining channels free of scale/corrosion.

Comparison of Cooling Methods

| Method | Best For | Cycle Time Impact | Cost |

|---|---|---|---|

| Water Cooling | High-volume aluminum | High reduction | Low |

| Oil Cooling | Magnesium alloys | Moderate | Medium |

| Conformal | Complex geometries | Very high | High (3D print) |

| Air Cooling | Prototypes/small parts | Low | Very low |

Real-World Example

In automotive die casting (e.g., engine blocks):

- Water cooling dominates due to its efficiency.

- Channels are drilled near critical areas like cylinder walls to ensure rapid, uniform solidification.

By tailoring the cooling system to the specific alloy, part geometry, and production needs, manufacturers achieve high-quality castings with minimal waste and maximum throughput. Advances like conformal cooling and smart temperature control are pushing the boundaries of precision and sustainability in the industry.

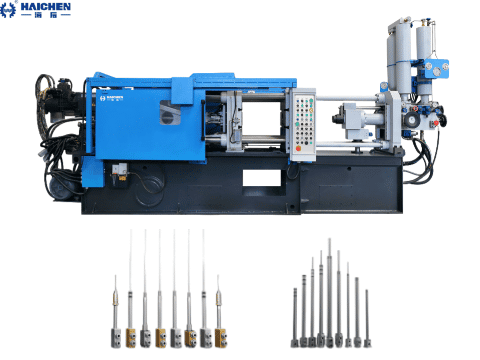

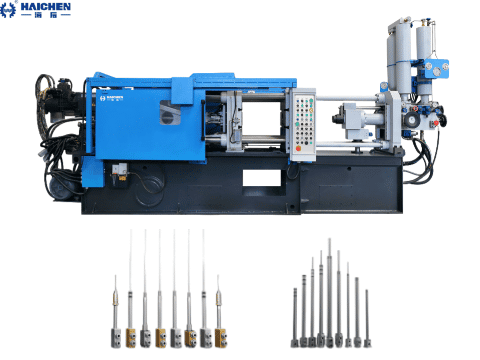

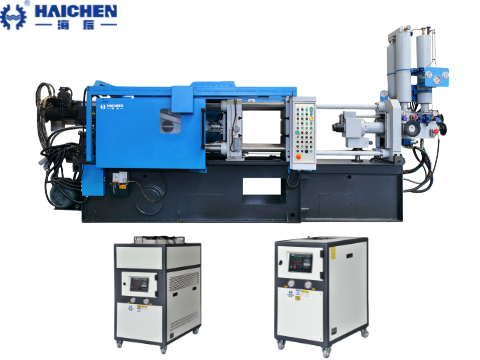

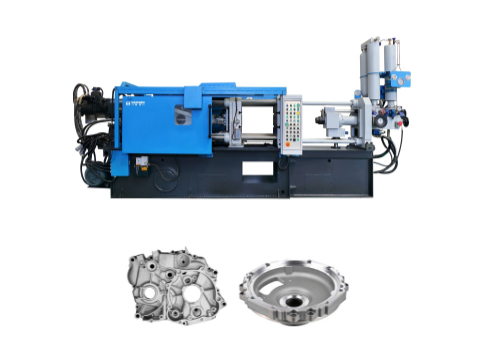

Excellent cooling system for Haichen die casting machine

- Intelligent temperature control and monitoring

- Efficient cooling water channel design

- Structural optimization and dynamic analysis

- Integrated cooling and lubrication system

- Energy saving and automation design

- Application cases and industry adaptation

Intelligent temperature control and monitoring

Real-time temperature feedback and adjustment:

Haichen’s die-casting machine uses thermocouples to monitor the mold temperature, and the set value is compared in real time through the built-in intelligent system of the die-casting machine.

When the temperature exceeds the upper limit (such as 205℃), the system will automatically open multiple sets of cooling water solenoid valves to achieve precise temperature control.

This closed-loop control significantly improves the stability of casting quality.

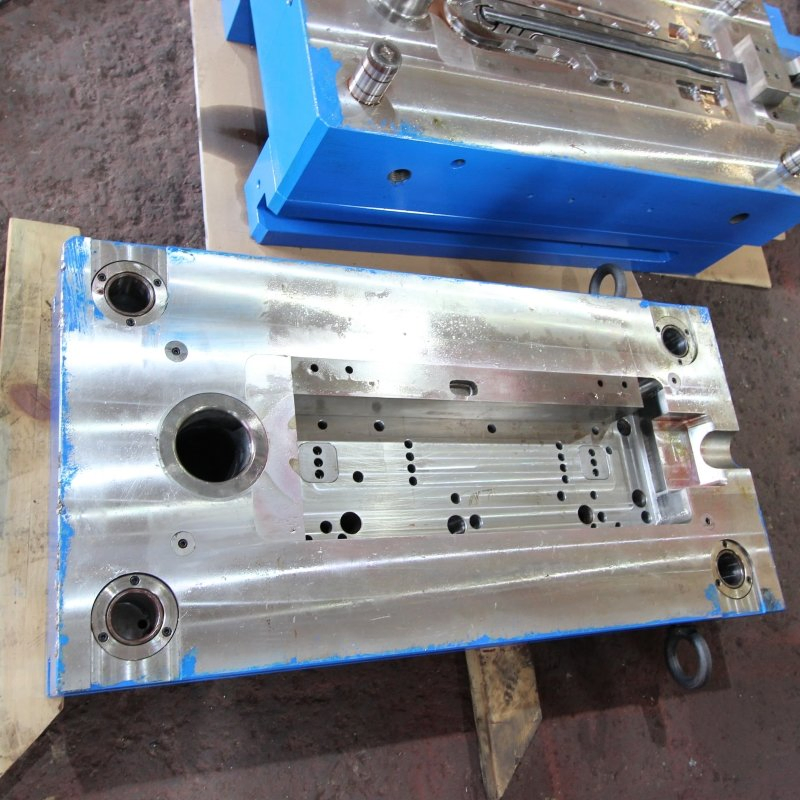

3D printing insert technology:

In complex castings (such as motor housings), 3D printing inserts are embedded in key areas of the mold (such as high-temperature area G), and combined with a high-pressure cooling system to achieve local rapid heat dissipation and effectively avoid thermal stress concentration.

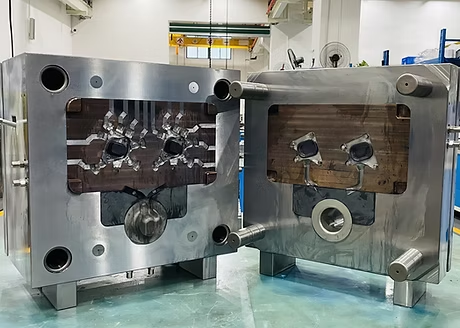

Efficient cooling water channel design

Multi-channel cooling system:

Multiple Φ10 mm cooling water channels are set inside the mold, distributed along the length of the cavity, and connected to the fixed mold insert through a nozzle to form a circulating water channel.

For example, in the production of thick-walled castings, the layout of the cooling water channel takes into account both heat dissipation efficiency and structural interference issues to ensure uniform cooling.

High-pressure spot cooling technology:

For areas with long solidification time (such as gearbox housing), high-pressure spot cooling mechanism is used to cool down separately, combined with the overall water channel to form a graded cooling strategy to optimize the thermal balance of the mold.

Structural optimization and dynamic analysis

Finite element analysis to enhance cooling effect:

Haichen conducts finite element dynamic analysis on all key components (such as templates and tie rods) during the design stage to ensure reasonable stress distribution and reduce thermal deformation.

For example, the design of thickened plate and roughened tie rod maintains injection coaxiality for a long time, indirectly improving the stability of the cooling system.

Oblique five-point clamping structure:

Compared with the traditional straight structure, the oblique design enhances the clamping strength and stability, reduces the displacement of the mold at high temperature, and thus optimizes the sealing and efficiency of the cooling channel.

Integrated cooling and lubrication system

Central oil lubrication and cooling water linkage:

The machine is equipped with an automatic central oil lubrication system, which triggers an alarm when the oil volume is low. At the same time, the cooling water system and the lubrication system work together to prevent local overheating caused by insufficient lubrication.

Independent oil cooling and water cooling system:

The independent oil cooling device (such as oil-cooled air conditioner) and oil-water dual cooling design of the servo hydraulic system ensure efficient heat dissipation of hydraulic oil and cooling oil, and avoid performance degradation caused by excessive oil temperature.

Energy saving and automation design

Servo energy saving technology:

Haichen’s high-performance servo system (such as Haitian servo) reduces ineffective energy consumption by precisely controlling the oil pump flow and pressure, and at the same time combines efficient cooling methods (such as fin heat transfer tubes) to reduce the overall cooling load.

Automated coolant management:

The die-casting unit is equipped with a short-circuit ball valve and flow meter to dynamically adjust the cooling water flow during production, and automatically switch to short-circuit mode when shutting down to maintain system temperature stability.

Application cases and industry adaptation

Aluminum radiator and pot production:

In view of the high thermal conductivity of aluminum, Haichen’s cold chamber die-casting machine shortens the filling time and reduces the heat load of the mold by optimizing the injection speed (up to 8m/s) and boost control (precise control by pressure sensor).

At the same time, the Teflon-coated mold surface further reduces the risk of sticking.

Automotive parts manufacturing:

In large castings (such as engine blocks), the dual systems of “water-cooled material temperature” and “temperature range control” are used to handle the heat dissipation requirements of the mold and hydraulic unit respectively, ensuring efficient production and long mold life.

More we can tell

The cooling system of Haichen die-casting machine has achieved a dual improvement in casting quality and production efficiency through intelligent temperature control, structural optimization, efficient water channel design and energy-saving technology.

Its core advantage lies in the combination of dynamic analysis, intelligent feedback and modular cooling solutions to adapt to the diversified production needs from small and medium-sized parts to large automotive structural parts.

You are welcome to leave a message to get more technical support related to die casting.