Die Casting and Metal Forging are two different metal forming processes.In metal forging, the workpiece material is heated (often to extremely high temperatures) while remaining solid. In die casting, the metal is heated until it is completely molten. Forging relies on physical force to push solid metal into an open die to shape it, while die casting uses air or hydraulic pressure to force molten metal into a completely enclosed die.

Although both involve heating metal and using a forming device called a die, there are significant differences between die casting and metal forging. Die casting offers a distinct advantage over forging: it can be used with a wide range of alloys, including materials such as aluminum, magnesium, zinc, and copper. Forging can handle iron, steel, and titanium, materials that cannot withstand melting temperatures in casting. Die casting dies are generally less expensive than forging dies because they are subjected to far less stress during the manufacturing process.

Die casting is better suited to parts with complex shapes and fine geometries, and its finished products have a surface finish far superior to forgings, while also offering faster production speeds and greater capacity.Haichen Die Casting Machine Company Having worked in this industry for many years, I am ready to provide you with professional services.

There are significant differences in material applicability, process characteristics, product performance and application scenarios.

Detail differences between Die Casting and Metal Forging processes

- Process Principle

- Material Applicability

- Product performance

- Cost and production efficiency

- Typical Applications of Die casting and Forging

- Other key differences between Die casting and Forging

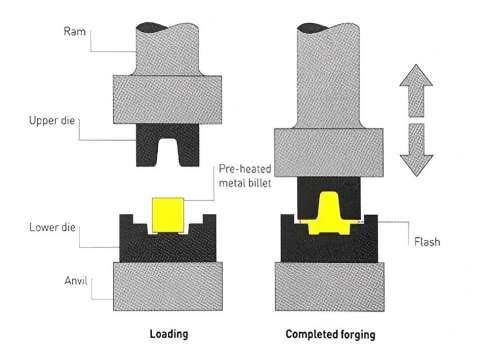

Process Principle

Die Casting

Molten non-ferrous metals (such as aluminum, zinc, and magnesium alloys) are injected into the steel mold cavity under high pressure and cooled to form precision parts.

This process is suitable for mass production of thin-walled parts with complex shapes and high surface finish.

Forging

By applying compression force (hammering or press) to heated solid metal (ferrous metals such as steel, or non-ferrous metals such as aluminum and titanium), it is plastically deformed and formed.

Forging is divided into cold forging, warm forging and hot forging, which can improve the grain structure and mechanical strength of the material.

Material Applicability

Die Casting

Only suitable for non-ferrous metals such as cast aluminum alloys, zinc alloys, magnesium and copper alloys.

Ferrous metals are prone to damage molds due to their high melting point and are usually not used for die casting.

Forging

Applicable to ferrous metals (such as steel, stainless steel) and non-ferrous metals (such as aluminum, titanium, nickel-based alloys), with a wider range of material selection.

Product performance

Die casting

Advantages: high dimensional accuracy, can produce complex shapes and thin-walled parts, good surface quality, suitable for lightweight needs.

Disadvantages: Porosity or shrinkage may occur inside the parts due to rapid cooling, and heat treatment strengthening is usually not possible.

Forging

Advantages: Refine the grains through plastic deformation, improve the tensile strength, fatigue strength and impact resistance of the material, and the parts have high density and no pores.

Disadvantages: The complexity of the shape is limited, and it is difficult to manufacture deep cavities or fine structures.

Cost and production efficiency

Die casting

The mold cost is high, but it is suitable for large-scale production, and the unit cost is low; the production efficiency is extremely high (such as the die casting machine can complete multiple injections per minute).

Forging

The mold needs to withstand high pressure impact, and the tool steel mold cost is higher; it is suitable for small and medium batches or high-strength parts, but the production cost is low when the shape is simple.

Typical Applications of Die casting and Forging

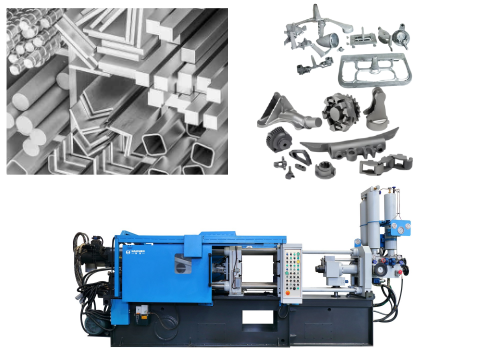

Die casting

Lightweight precision parts such as automotive parts (such as engine blocks, gearbox housings), consumer electronics housings, and medical devices.

Forging

Aerospace parts (such as engine blades, landing gear), heavy machinery (such as gears, crankshafts), and high-load tools (such as anchor chains and hooks).

Other key differences between Die casting and Forging

Weight:

For parts of the same design, die castings are usually lighter than forgings.

Post-processing requirements:

Die castings usually do not require additional machining, while forgings may require finishing to meet tolerances.

Environmental impact:

Forging requires high-temperature heating and high energy consumption; die casting molten metal processing may produce exhaust gas, but the material utilization rate is higher.

Summary

Choosing die casting or forging depends on specific needs:

Prefer die casting:

When complex shapes, thin-walled structures, large-scale production, and non-ferrous metals are required.

Prefer forging:

When high strength and impact resistance are required, the material is ferrous metal or needs to withstand extreme working conditions.

Haichen Die Casting machine company

Haichen Die Casting Machine Company is a Chinese company focusing on the research and development and manufacturing of high-pressure die-casting equipment, headquartered in Ningbo, Zhejiang. The following is the main information of the company:

- Company Profile

- Core Products

- Technical advantages

- Service and support

- Market Positioning

Company Profile

Founded in 2005, with more than 20 years of industry experience.

Production Base: The factory is located in Ningbo, equipped with full-process support such as sales, service, and R&D.

Market Distribution: Products are exported to India, Russia, Mexico, China and other countries or regions, especially in the automotive industry.

Core Products

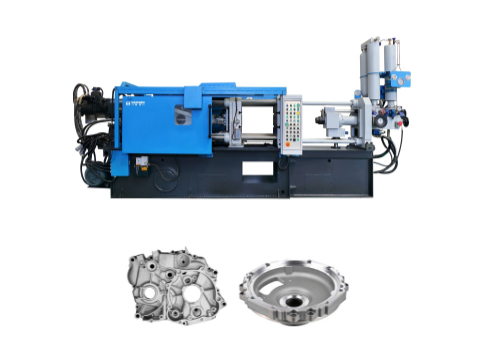

Cold Chamber Die Casting Machine

Applicable Materials: High-melting-point metals such as aluminum, magnesium, and brass (melting temperature exceeds 700°C).

Features: Clamping force range 500-30,000 kN, equipped with servo energy-saving system and real-time control system. Models such as the HCD series support large mold production, with larger template size and mold opening stroke.

Application Areas: Automotive parts (such as structural parts, radiators), LED lamp housings, building materials, etc.

Hot Chamber Die Casting Machine (Hot Chamber)

Applicable materials: low melting point metals such as zinc and lead.

Features: tonnage range 15-280 tons, integrated design of furnace and machine, fast injection speed.

Application areas: precision parts such as lock parts, door handles, pipe fittings, etc.

Auxiliary equipment

Provide automation solutions, including manipulators, sprayers, pick-up machines, etc., to support intelligent production processes.

Technical advantages

Control system: Siemens PLC is used, which supports multi-language interface (such as English, Spanish, Russian) and stores multiple sets of mold parameters.

Hydraulic components: Select well-known European and American brands (such as Vickers, Sannishi) to ensure high stability and reliability.

Energy-saving technology: Servo energy-saving system reduces energy consumption and displays injection curves in real time to optimize the process.

Certification standards: Passed ISO 9001 and CE certification, in line with international safety and quality standards.

Service and support

Solution: Provide one-stop service from mold design, mold flow analysis to equipment configuration.

Warranty policy: The warranty period starts from the date of equipment delivery. The warranty service can only be enjoyed if the equipment is operated correctly, covering hydraulic components, electrical components, etc.

Maintenance Guide: Emphasize regular lubrication (such as adding lubricants every half month), cleaning of the hydraulic system and inspection of components to extend the life of the equipment.

Market Positioning

Industry Cooperation: Closely cooperate with customers to promote die-casting technology innovation, involving vacuum casting, squeeze casting and other fields.

Competitive Advantage: Known for its high cost-effectiveness, fast delivery and reliable after-sales support, it is especially suitable for large-scale production of complex thin-walled parts.

Notes

Haichen Die Casting Machine Company has become an important player in the die-casting industry with its diversified product lines, advanced technology configuration and global market layout, especially in the field of medium-sized die-casting equipment.

Contact us at any time and let us provide stronger support for your metal products industry.