Precision die casting advantages include high precision and consistency, capability to produce complex geometries and so on.

Precision Die Casting has several significant advantages. That makes it an ideal choice for manufacturing complex, high-precision metal parts.

Precision die casting occupies an important position in modern manufacturing due to its advantages such as high precision, complex shape production capability, excellent surface quality and mechanical properties, high production efficiency and wide range of material selection. These advantages make it the preferred manufacturing process in many industries such as aerospace, automobile, electronics, etc.

Advantages of precision die casting mainly include:

- High Precision and Consistency

- Capability to produce complex geometries

- Excellent mechanical properties

High Precision and Consistency

Precision die casting is able to produce parts with tight tolerances and high dimensional accuracy through carefully designed molds and controlled pouring processes.

This accuracy can usually reach ±0.1 mm (first 2.5 cm), and decrease by 0.02 mm for every additional cm.

- Extremely High Dimensional Accuracy

- Dimensional Consistency and Repeatability

- Excellent Surface Quality

- Achieving Complex Geometric Shapes

In addition, the surface roughness of precision die casting parts is usually between Ra0.8 and 3.2 microns. This high precision makes it particularly suitable for industries such as aerospace, automotive, and electronics.

Extremely High Dimensional Accuracy

- Through high-pressure injection and precision molds, die-cast parts can achieve tolerances of ±0.01mm or even ±0.002in, meeting stringent assembly requirements.

- This precision significantly reduces subsequent processing (such as drilling and tapping), even enabling “net-shape” production.

Dimensional Consistency and Repeatability

- Strict process control and automated equipment maintain consistent fill speed and pressure for every shot, ensuring dimensional tolerances within ±2mm for each part, meeting high consistency requirements.

- Reusable molds and standardized process parameters ensure highly consistent part shape, size, and surface quality across large-scale production.

Excellent Surface Quality

- The mold surface directly determines the surface finish of the casting, often achieving Ra1–2.5µm (approximately 0.04–0.10 thou rms), significantly reducing post-processing steps.

- High-quality surfaces not only enhance aesthetics but also reduce costs for subsequent painting and polishing.

Achieving Complex Geometric Shapes

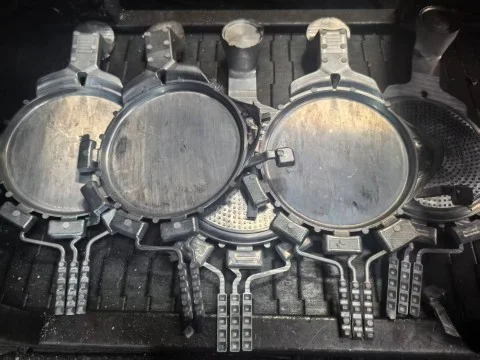

- Precision die casting enables the formation of complex structures such as internal channels, threads, and heating elements in a single step, ensuring dimensional accuracy while enabling design freedom.

- This is particularly important for products requiring high detail, such as electronic housings and automotive parts.

Capability to produce complex geometries

- Excellent surface quality

- High production efficiency

- Wide selection of materials

Precision die casting is able to produce parts with complex geometries, including thin walls, deep cavities, and complex internal structures. This capability gives precision die casting a significant advantage in manufacturing complex components, such as automotive engine parts, electronic equipment housings, etc.

Excellent surface quality

Precision die-cast parts usually have a smooth surface, reducing the need for subsequent processing.

This surface quality not only improves the appearance of the part, but also enhances its durability and functionality.

High production efficiency

Precision die casting is a high-speed production process that can produce a large number of parts in a short period of time.

This high efficiency makes it suitable for large-scale production while reducing unit costs.

Wide selection of materials

Precision die casting can use a variety of metal materials, including aluminum, zinc, magnesium and copper alloys.

This range of material selection enables precision die casting to meet the needs of different industries.

Haichen advantages of precision die casting case

Haichen die casting machines demonstrate their advantages in precision die-casting through high accuracy, exceptional consistency, and superior surface finishing capabilities. The precision die-casting process enables the single-step formation of complex structures while ensuring highly precise component dimensions, which is crucial for numerous demanding products.

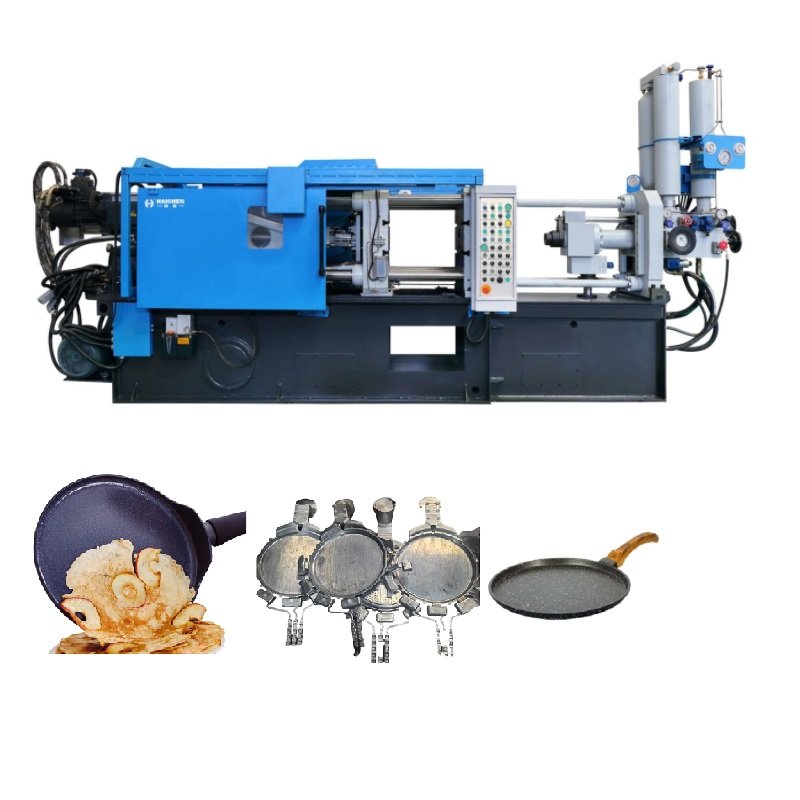

Aluminium frying pans precise die casting

Pan bodies produced using Haichen precision die-casting machines exhibit exceptional uniformity in wall thickness. This not only optimises heat transfer efficiency for more even heating but also significantly enhances the product’s overall structural strength and service life, preventing localised overheating or deformation caused by uneven thickness.

Die casting advantage of aluminium alloy cookware handles

For handles requiring intricate textures and precise assembly dimensions, precision die casting guarantees consistent detail clarity and accurate connection points with the pan body. This achieves secure assembly while providing a comfortable, non-slip grip, enhancing user experience.

Zinc alloy Medals precise die casting

The advantages of precision die-casting are particularly pronounced in the production of zinc alloy medals or commemorative badges. It perfectly replicates the most minute patterns, text, and textures on the mould, yielding castings with a high surface finish. Subsequent processing requires only simple polishing or electroplating to achieve exquisite finished products, significantly reducing post-production costs and time.

Excellent mechanical properties

- Dimensional stability

- Long mold life

- Versatility and integration

Precision die-cast parts have high strength, hardness and durability. Because the liquid metal solidifies quickly under high pressure, the internal structure of the parts is dense and uniform, which improves its mechanical properties.

Dimensional stability

Precision die-cast parts show good dimensional stability during use and can maintain their accuracy even in harsh environments.

Long mold life

Precision die-casting molds have a long service life.

For example, zinc-based molds can reach one million injections, copper-based molds can reach 750,000 times, and aluminum-based molds can reach 500,000 times.

This long life further reduces production costs.

Versatility and integration

Precision die casting can integrate multiple functions into one part, such as embedded threads, bosses, and ribs.

This integration reduces assembly cost and complexity.

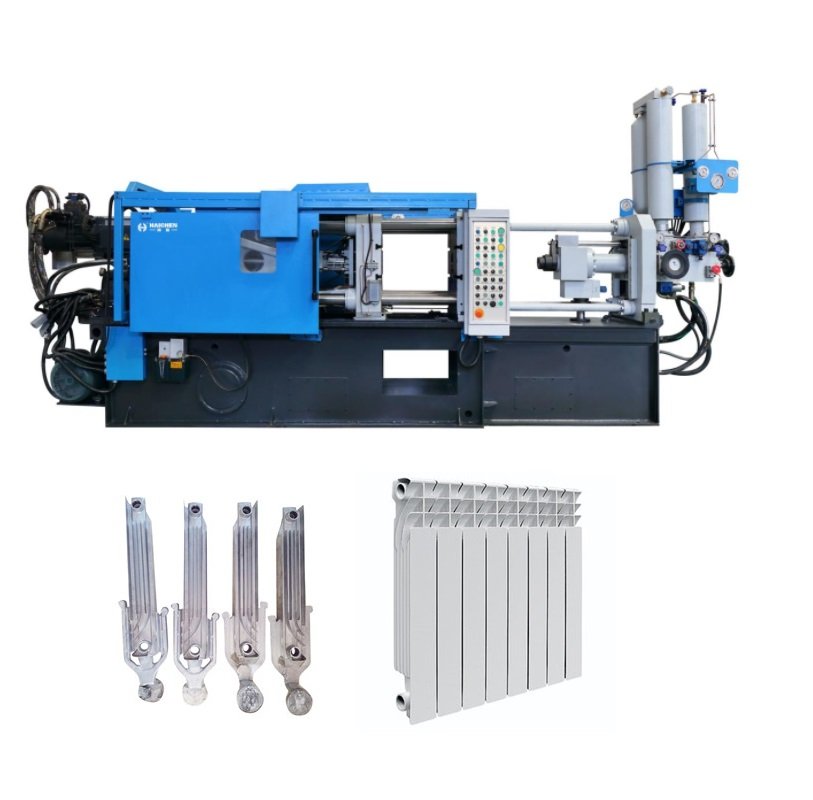

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.