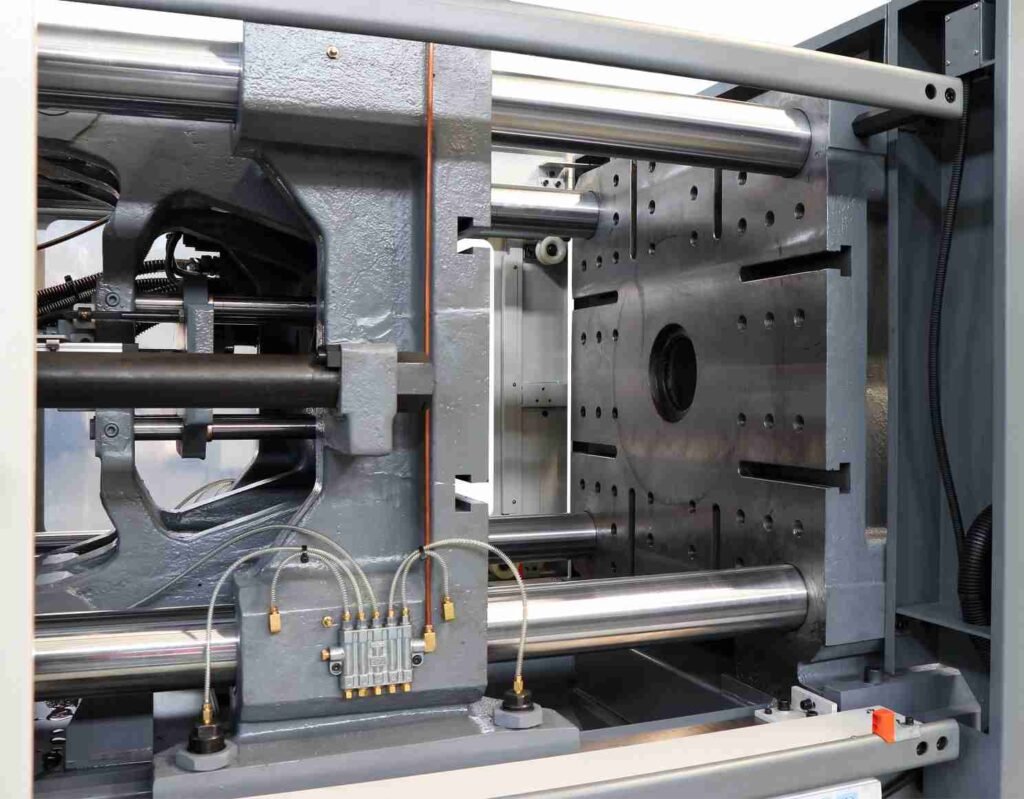

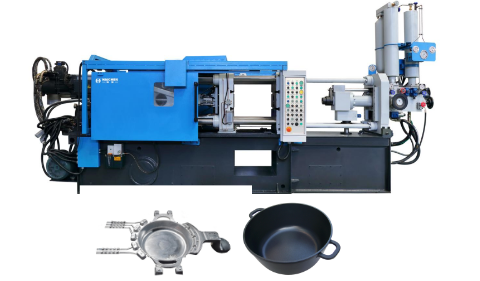

Die casting machine tie bar (also called tie rods or columns) are critical components in die casting machines, providing structural integrity and ensuring precise alignment during the casting process.

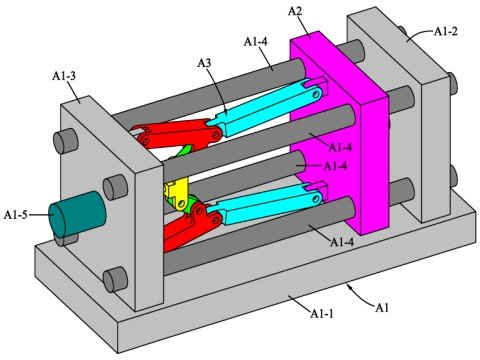

In automatic tie bar withdrawal devices, the tie bar nuts on the fixed fixing plate are split . First, the split tiebar nuts are opened with a hydraulic actuating cylinder. Then the tiebar nuts are unlocked from the movable fixing plate.

The overall tie bar assembly maintains the stress balance inside the overall clamping component when the die casting machine is running.

Detailed explanation of the pull rod operation function

Let’s break down the actual process

- Structural Support and Clamping Force Distribution

- Mold Alignment and Parallelism

- Adjustment for Mold Thickness

- Absorption of Thermal Expansion

- Safety and Load Balancing

Structural Support and Clamping Force Distribution

- Role:

- Tie bars connect the stationary platen (fixed mold half) and moving platen (ejector mold half), forming a rigid frame.

- They withstand the clamping force (up to thousands of tons) generated by the machine to keep the mold closed during injection.

- Importance:

- Prevents mold deformation under high pressure.

- Distributes clamping force evenly across the mold surface.

Mold Alignment and Parallelism

- Role:

- Tie bars ensure the two mold halves remain perfectly aligned during clamping and injection.

- Maintain parallelism between platens to avoid uneven parting lines or flash.

- Importance:

- Reduces defects like misalignment-induced porosity or incomplete fills.

- Extends mold life by minimizing wear from uneven contact.

Adjustment for Mold Thickness

- Role:

- Tie bars can be mechanically adjusted (via nuts or hydraulic systems) to accommodate molds of different thicknesses.

- Allows the machine to switch between molds for varying part sizes.

- Importance:

- Enhances machine flexibility for multi-product production.

- Simplifies mold setup and reduces downtime.

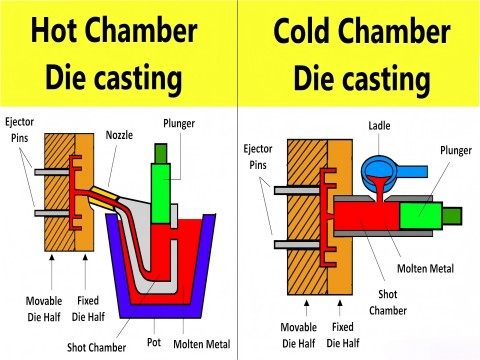

Absorption of Thermal Expansion

- Role:

- During operation, heat from molten metal and friction causes components to expand.

- Tie bars are designed to absorb thermal expansion without losing clamping force.

- Importance:

- Maintains consistent clamping pressure during prolonged cycles.

- Prevents mold damage due to thermal stress.

Safety and Load Balancing

- Role:

- Tie bars act as fail-safes, containing energy in case of hydraulic system failure.

- Balance dynamic loads during high-speed mold movements.

- Importance:

- Protects operators and equipment from sudden mechanical failures.

- Reduces vibration and noise during operation.

Key Considerations for Tie Bars

- Material: Made from high-tensile steel (e.g., 42CrMo4) to endure cyclic stress.

- Preload: Proper pre-tensioning ensures tie bars remain elastic under maximum load.

- Maintenance: Regular inspection for fatigue cracks, corrosion, or elongation is critical.

Tie Bar Specifications in Die Casting Machines

| Parameter | Typical Range |

|---|---|

| Diameter | 100–300 mm (depends on machine size) |

| Tensile Strength | 800–1,200 MPa |

| Preload Force | 60–70% of yield strength |

Common Issues & Solutions

- Elongation: Over time, tie bars may stretch, reducing clamping force. Solution: Re-tension or replace.

- Misalignment: Worn tie bars cause uneven mold closure. Solution: Laser alignment checks.

- Corrosion: Exposure to coolants or humidity. Solution: Coatings (e.g., chrome plating).

What is die casting machine tie bar distance?

The tie bar distance (also known as tie bar spacing or tie bar clearance) in a die casting machine refers to the horizontal and vertical space between the tie bars, which determines the maximum size of the mold that can be accommodated. It is a critical specification for ensuring compatibility between the machine and the mold. Here’s a detailed explanation:

- Definition

- Key Functions

- How It’s Measured

- Importance in Die Casting

- Typical Tie Bar Distances

- Tie Bar Distance vs. Other Specifications

- Example Scenario

- Common Challenges

Definition

- Tie Bar Distance:

- The horizontal and vertical measurements between the centers of adjacent tie bars.

- Defines the maximum allowable mold dimensions (width and height) that can fit into the machine.

Key Functions

- Mold Compatibility: Ensures the mold can physically fit between the tie bars without interference.

- Machine Flexibility: Dictates the range of mold sizes the machine can handle.

- Structural Integrity: Maintains alignment and rigidity during high-pressure clamping.

How It’s Measured

- Horizontal Tie Bar Distance: Distance between the left and right tie bars.

- Vertical Tie Bar Distance: Distance between the upper and lower tie bars.

- Example: A machine with a tie bar distance of 600 mm × 600 mm can accommodate molds up to 600 mm in width and height.

Importance in Die Casting

- Mold Size Limits: If the mold exceeds the tie bar distance, it cannot be installed.

- Production Constraints: Larger molds require machines with greater tie bar spacing.

- Adjustable Tie Bars: Some machines allow tie bars to be moved or removed for oversized molds (common in large-tonnage machines).

Typical Tie Bar Distances

| Machine Clamping Force | Tie Bar Distance Range |

|---|---|

| Small (100–500 tons) | 300–600 mm |

| Medium (500–2000 tons) | 600–1200 mm |

| Large (2000+ tons) | 1200–2500 mm |

Tie Bar Distance vs. Other Specifications

- Clamping Force: Determines the pressure to hold the mold closed (measured in tons).

- Daylight Opening: The maximum space between platens when fully open (mold height limit).

- Platen Size: The surface area for mounting molds, which must align with tie bar spacing.

Example Scenario

- Machine Specs:

- Clamping Force: 800 tons.

- Tie Bar Distance: 700 mm × 700 mm.

- Daylight Opening: 800 mm.

- Mold Requirements:

- Mold Width: 680 mm (fits within 700 mm tie bar spacing).

- Mold Height: 750 mm (fits within 800 mm daylight opening).

Common Challenges

- Oversized Molds: Exceeding tie bar spacing requires a larger machine or adjustable tie bars.

- Misalignment: Improperly spaced molds cause uneven clamping force and defects like flash.

The tie bar distance is a foundational specification in die casting machines, defining the physical limits for mold size. Always verify this parameter when selecting a machine to ensure your mold fits and operates efficiently. For specialized applications (e.g., large automotive components), opt for machines with adjustable tie bars or retractable tie rod systems to maximize flexibility.

What we want to tell

Tie bars are the backbone of die casting machines, ensuring precision, safety, and durability. Their ability to handle extreme forces while maintaining alignment makes them indispensable for producing high-quality cast parts. For optimal performance, prioritize regular maintenance and invest in machines with robust tie bar designs (e.g.,Haichen Bühler, Toshiba, or L.K. Technology).

Please feel free to contact us, Haichen will provide you with complete die casting information.