Die cast mold tooling guide includes mold material selection, mold structure and components,mold design and optimization etc.

The die casting mold is the prime instrument used in the die casting process. It is an important tool as the final product heavily relies on selection of the proper cooling system, ejection system, parting line, and even the geometric designs. Having proper mold designs ensures that the required industry standards are fulfilled, and in turn, guarantees the production of high precision castings.

Careful and precise maintenance on die-casting molds also ensures the system remains operational for a long time. Generally, we expect the die-casting molds to have high temperature resistance, and strong structural integrity, whilst remaining economical. They also need to be durable enough to withstand the expected production volume, alloy type and precision needs. For aluminum alloy die-casting, H13 steel is the gold standard, while P20 steel or aluminum alloy is a good low-cost alternative. Proper testing and rigor in the materials used in the heat treatment process is also crucial.

We will analyse die cast mold tooling guide from blew aspects:

- Mold material selection of die cast mold tooling guide

- Mold structure and components

- Mold design and optimization

- Mold maintenance and improvement

Mold material selection of die cast mold tooling guide

- Matching Working Conditions

- Based on product scale and life requirements

- Affordability and Processability

- Aluminum Alloy Die Casting

- High-precision Large Molds

- Repair Welding Materials of die cast mold tooling guide

- Pre-processing Inspection

- Heat Treatment Process

- Welding Repair Specifications

Die casting molds are usually made of heat-resistant tool steels, such as H13, SKD61, DAC, FDAC, etc. These materials have good wear resistance and high temperature performance.

Matching Working Conditions

- The material must withstand high temperatures (molten metal temperatures can reach 600-700°C). And the high pressures (typically 70-150 MPa), and possess high thermal conductivity. Wear resistance, thermal fatigue resistance, and dimensional stability.

- Components in direct contact with the molten metal (such as the mold cavity) must be made of high-quality heat-resistant steel. So it can resist thermal deformation and corrosion.

Based on product scale and life requirements

- For large-scale production: High-performance hot-work die steels (such as H13 and 8407) prefer to ensure long life.

- For small-batch or prototype molds: they can use lower-cost pre-hardened steels (such as P20) or aluminum alloys.

- The larger the mold size and the more complex the structure, the higher the material performance requirements, and a satisfactory strength-to-weight ratio must be met (for example, a cavity depth to mold thickness ratio of <1:3).

Affordability and Processability

- While meeting performance requirements, select materials with good processability and stable heat treatment processes to reduce costs.

- For example, P20 steel is relatively low-cost and suitable for aluminum alloy die casting, but its high-temperature performance is inferior to H13.

Aluminum Alloy Die Casting

Preferred are H13 steel (best overall performance) or P20 steel (low-cost option).

Avoid low-carbon steel (poor pressure and heat resistance).

High-precision Large Molds

It require High-purity, fine-grained steel (such as imported SK61 and DACS5). And metallographic and ultrasonic testing perform in advance.

Repair Welding Materials of die cast mold tooling guide

Select solder based on the base material (e.g., nickel-chromium alloy for H13 molds).

Pre-processing Inspection

Before processing, the material must undergo visual inspection, metallographic analysis, and ultrasonic testing to eliminate internal defects.

Heat Treatment Process

Ensure the material reaches a uniform hardness (HRC 44-48) to avoid thermal stress cracking.

Welding Repair Specifications

After welding, it require slow cooling and annealing. Direct quenching is not permitted. And then it should remove the weld beading.

Mold structure and components

- Molding System of die cast mold tooling guide

- The fixed die

- The movable die

- Molding System of die cast mold tooling guide

- Gating System of die cast mold tooling guide

- Overflow System of die cast mold tooling guide

- Ejector System of die cast mold tooling guide

- Mold Base System of die cast mold tooling guide

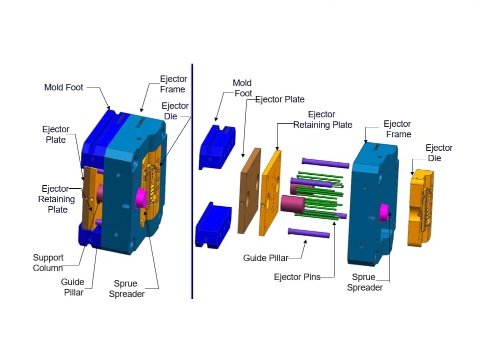

The structure of the die-casting mold includes the rear mold, front mold, mold frame, mold core, guide pin, guide sleeve, push rod, driver, slider, gate system, etc. The manufacturing of the mold involves precision processing equipment, such as milling machines, CNC machining centers, wire cutting machines, etc.

Core Structure: Fixed Die and Moving Die

A die casting mold consists of two main parts: the fixed die (fixed die) and the movable die (movable die).

The fixed die

Attached to the die mounting plate of the die casting machine, it connects to the injection system (such as the pressure chamber or nozzle). It includes components such as the sprue bush, guide pins, and core, and is responsible for the initial injection of the molten metal.

The movable die

Attached to the die casting machine‘s center plate, it moves to open and close the mold. It includes the ejector mechanism, slider, and other components, and is responsible for ejecting the part after molding.

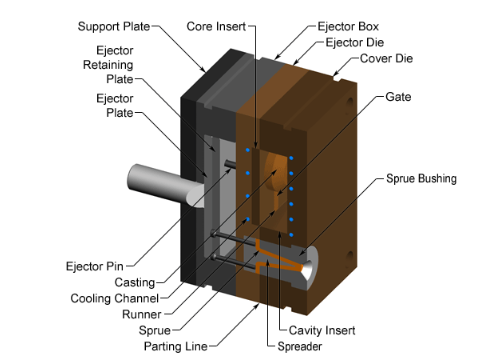

Molding System of die cast mold tooling guide

- Cavity: A cavity that matches the part’s shape and determines the final product’s geometric features.

- Core: A component that forms the part’s internal structure and works in conjunction with the cavity.

- Inserts and Sliders: Used to mold complex structures (such as side holes and threads) and require specialized motion mechanisms.

Gating System of die cast mold tooling guide

- Sprue: The channel through which molten metal enters the die from the die-casting machine.

- Runner: Guides the metal flow from the sprue to the inner gate, controlling flow direction and speed.

- Gate: The entrance through which the melt enters the cavity. Dimensions must meet fluid dynamics requirements (such as avoiding turbulence).

Overflow System of die cast mold tooling guide

- Overflow Slots: Collect cold metal and gas, reducing defects such as cold shuts and air holes.

- Venting Slots and Vent Plugs: Vent plugs are added to deep cavity areas to ensure effective gas discharge.

Ejector System of die cast mold tooling guide

- Ejector Pins: Eject the molded part. Critical areas (such as the gate) must be made of the same material as the part.

- Reset Parts and Guided Ejection: Ensure precise ejection of the ejector pins to avoid interference.

Mold Base System of die cast mold tooling guide

- Steel Plates and Frames: Combine the various mold components and support the overall structure.

- Guide Pins and Guide Bushes: Ensure precise alignment of the movable and fixed molds to reduce wear.

- Locking Modules: Such as wedges and inclined guide pillars, enhance mold clamping stability.

Mold design and optimization

- Draft Angle

- Reinforcement Ribs and Corner Fillets

- Wall Thickness Control

- Modular Design

- Venting Design of die cast mold tooling guide

- Advanced Technologies and Trends

- Smart Mold Technology

- Rapid Tooling Technology

- Mold Maintenance Strategies

Mold design is a critical step in the die casting process, which directly affects the shape, quality and consistency of the product. When designing, factors such as part geometry, we should consider material selection and production volume, and optimize CAD software used.

Draft Angle

The draft angle of the inner wall (typically 1°–3°) should be greater than that of the outer wall to prevent mold jamming. The angle increases with wall depth.

Reinforcement Ribs and Corner Fillets

- Reinforcement Ribs: Increase part rigidity, reduce wall thickness and weight, but avoid stress concentration.

- Corner Fillets: All intersections should radiuse (R ≥ 0.5mm) to improve metal flow and reduce the risk of mold thermal cracking.

Wall Thickness Control

Maintain uniform wall thickness (recommended 2–5mm) to avoid areas of excessive thickness that may cause shrinkage. Use reinforcement ribs to bridge uneven areas.

Modular Design

Use interchangeable modules (such as standardized mold bases) to shorten manufacturing cycles and accommodate a wide variety of production options.

Venting Design of die cast mold tooling guide

Add venting grooves (0.03–0.05mm deep) to complex structures or thin-walled areas to reduce air holes.

Advanced Technologies and Trends

CAE/CAD Integrated Applications

3D modeling combined with flow simulation (such as semi-empirical model analysis) optimizes casting plans in advance and reduces mold trial costs.

Smart Mold Technology

Embedded sensors monitor pressure and temperature in real time, dynamically adjusting parameters through AI to improve yield.

Rapid Tooling Technology

Prototype molds utilize laser sintering or direct metal deposition to shorten lead times (suitable for small batches).

Mold Maintenance Strategies

Regularly clean and polish the mold cavity, repair cracks (welding/coating), and record wear data to predict mold life.

Die cast mold tooling guide: Mold maintenance and improvement

- Routine Maintenance and Cleaning

- Lubrication and Lubricant Selection

- Temperature Control

- Storage and Environmental Management

Molds may wear or deform during use, so they need to be inspected and maintained regularly. Design improvements such as adding fillets and ribs can extend mold life and reduce production errors.

Routine Maintenance and Cleaning

- Routine maintenance of molds is crucial to maintaining their performance and extending their lifespan. Regularly cleaning the mold surface and interior to remove residual metal debris, oil, and other impurities can effectively prevent corrosion and damage.

- Use appropriate tools, such as wire brushes, for cleaning, and ensure proper lubrication to reduce friction and wear.

- Additionally, regularly inspect all mold components, including the cooling system and injection molding system, to promptly correct any problems before they escalate.

Lubrication and Lubricant Selection

- Lubrication is an essential component of mold maintenance. Sliding and friction components require regular lubrication to ensure smooth and unobstructed mold operation.

- Selecting a lubricant that is compatible with the mold material and alloy can effectively prevent wear and damage.

- Furthermore, lubricant usage should follow the manufacturer’s recommendations for optimal results.

Temperature Control

- Mold temperature control has a significant impact on production quality and mold life. Preheating the mold to the appropriate temperature and maintaining a stable temperature during production can prevent thermal stress and dimensional deviation.

- Excessively high or low temperatures can damage the mold, so strict temperature control is essential.

Storage and Environmental Management

- The storage environment of molds significantly affects their lifespan. Molds should be stored in a dry, clean, and flat area, away from moisture and contaminants. Before storage, thoroughly clean the molds to remove any residual cooling water and oil.

- Use locking plates to secure the movable plate and molds to prevent accidental opening. Additionally, similar molds should be stored separately for easier management and maintenance.

Application and selection of molds

Die-casting molds widely use in the molding of metals such as aluminum, zinc, and magnesium, and are suitable for mass production. We can select different mold materials and designs according to different production requirements.

The die casting mold tooling guide covers the entire process from material selection and design optimization to manufacturing and maintenance, emphasizing the core role of the mold in the die casting process and its impact on product quality.

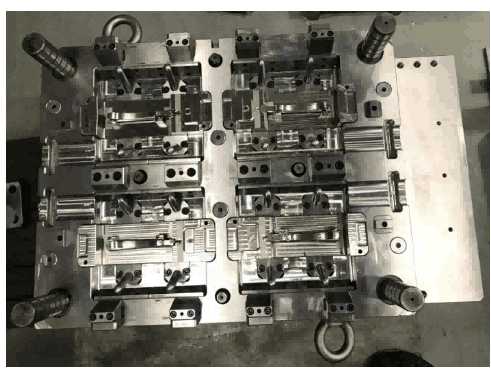

Die cast mold tooling guide for Haichen case

This case shows HAICHEN’s mold tooling process for a real high pressure die casting part.

- Part Analysis and Tooling Goals

- Mold Design and Build Process

- Result and Performance in High Pressure Die Casting

Part Analysis and Tooling Goals

One Haichen customer needed a mold for an engine part made by high pressure die casting, for example the aluminum crankcase. This part had complex shapes and thin walls. The main goal was to build a mold that could make many parts fast and with good quality. The mold needed to work well under the high force and high temperature of the high pressure die casting process.

Mold Design and Build Process

HAICHEN engineers first used software to design the mold. They planned the gates and cooling lines with care. This step is key for smooth metal flow and fast cooling in high pressure die casting. Then, they used strong steel to make the mold. They used precision machines to make every detail exact. The mold got special coatings to resist wear from the hot metal. This makes the mold last longer in high pressure die casting production.

Result and Performance in High Pressure Die Casting

The finished mold met all goals. It made high-quality parts in the high pressure die casting machine. The parts had few defects and needed little extra work. The mold showed good performance. It kept making good parts for a long production run. This case proves that good mold tooling is very important for success in high pressure die casting.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. At the same time, we produce both high pressure cold chamber die casting machine and hot chamber die casting machine. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.